39

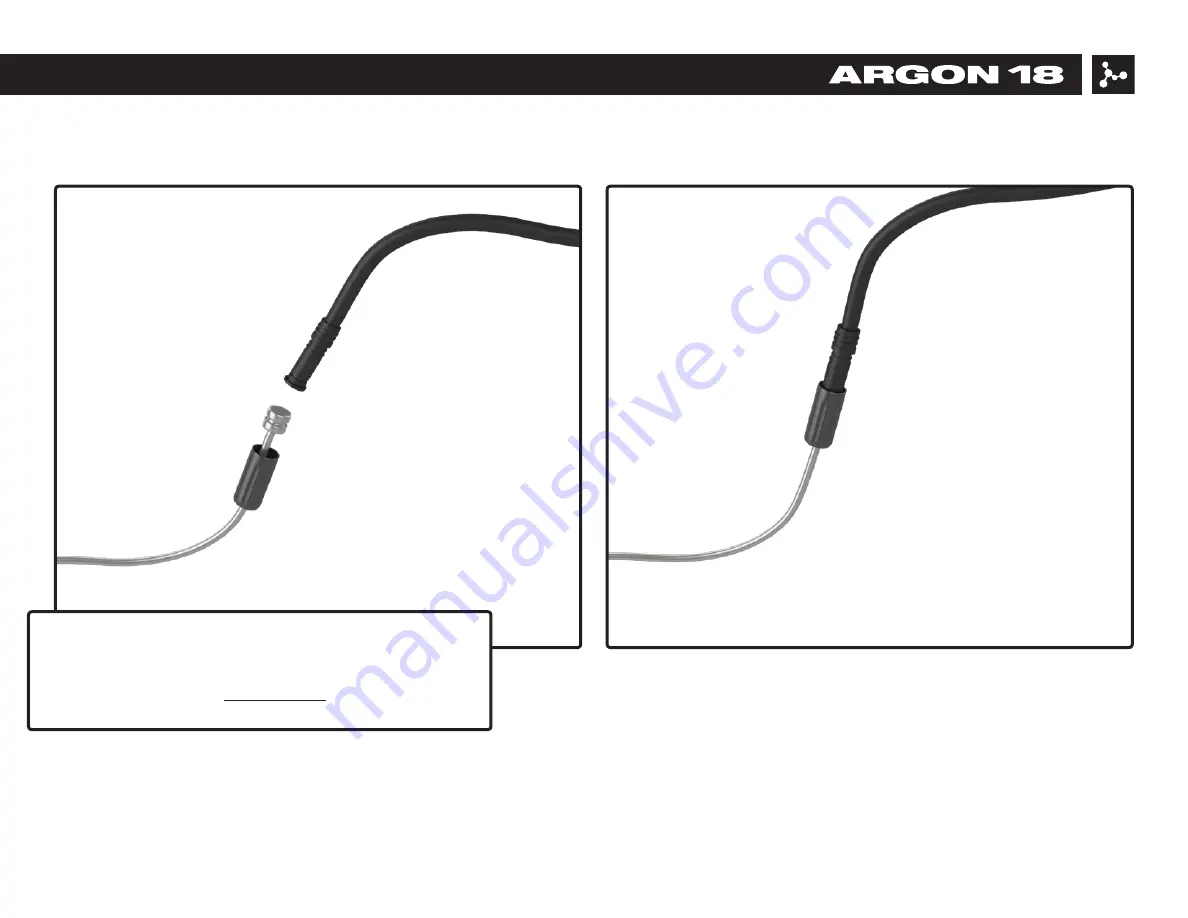

The Di2 cable routing can be achieved easily using this

simple trick: use a gear cable and a metal cable end to fix the

Di2 cable. For more information on Shimano Di2 electronic

system installation, go to: si.shimano.com.

E-119 TRI 233A: 13. Electronic Drive-train Specification