22

4.3 Torch switch control current

4.4 Argon Arc Welding Operation

4.4.1 TIG welding

(

4T operation

)

The start current and crater current can be pre-set. This function can compensate the possible crater that appears

at the beginning and end of the welding. Thus, 4T is suitable for the welding of medium thickness plates.

Pulsed TIG long welding

(

4T

)

:

t( s)

0

I( A)

Loosen the

switch

t1

t5

t7

Striking success

Stop arc

t3

t4

Base current setting

value

t2

t6

Loosen the

switch

Repress down the

switch

Start

current

Crater

current

Welding current (peak

current) setting value

Press and hold the

welding gun switch

Introduction

:

0

:

Press and hold the Torch switch, Electromagnetic gas valve is turned on. The

shielding gas starts to flow;

0

~

t1

:

Pre flow time, adjustment range of pre flow time :0.1~1.0S;

t1

:

Striking success, adjustment range of start current: 5~200A;

t2

:

Release the Torch switch, the output current slopes up from start current; if the output pulse

function is turned on, the output current is pulsed;

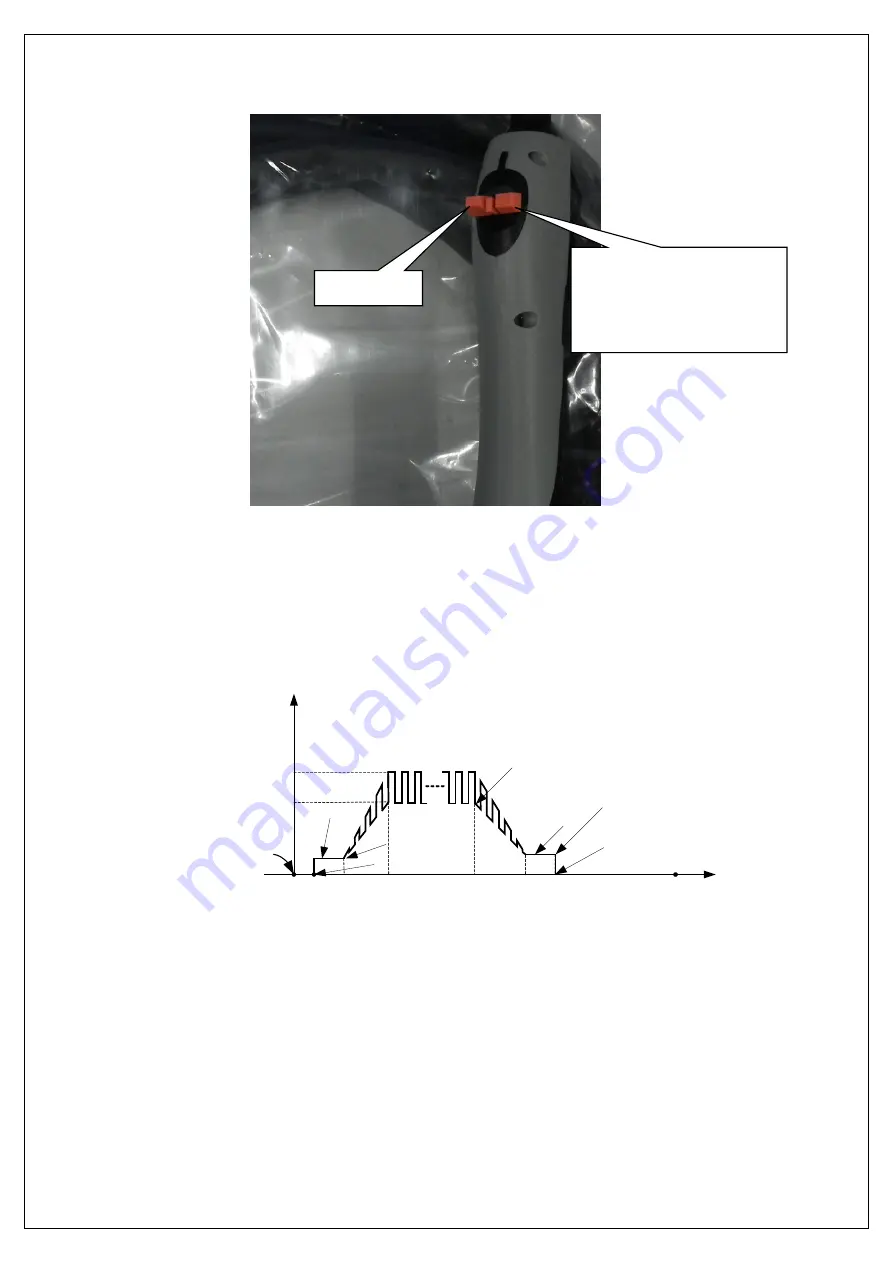

Torch switch

Adjust current button, when

it’s pushed up, the current

increases, when it’s pushed

down, the current decreases.