10

2580 series Hydraulic Installation Tools (HK961)

The operating efficiency of Huck equipment is directly

related to performance of the entire system, including tool,

nose assembly, hoses, trigger assembly, and Powerig®.

An effective preventive maintenance program includes

scheduled inspections of the system to detect and correct

minor troubles.

SYSTEM INSPECTION/PREVENTIVE MAINTENANCE

- Inspect tool and nose assembly daily for damage

and wear. Before each use, verify that the tool, hoses,

fittings, couplings, and trigger connections are secure,

undamaged, and free of leaks; replace as necessary. Clear

air-lines of dirt and water.

- Inspect tool, hoses, and Powerig during operation to

detect abnormal heating, leaks, or vibration.

- Service the tool in a clean, well-lighted area. Take

special care to prevent contamination of pneumatic and

hydraulic systems.

- Carefully handle all parts and components. Before

re-assembly, examine them for damage and wear;

replace when necessary. Replace O-rings and Back-up

rings whenever the tool is disassembled.

- Have available all necessary hand tools (standard and

special); a half-inch brass drift and wood block; an arbor

press; and a soft-jaw vise. Unsuitable hand tools could

damage tool. See

K

Its

& a

ccessorIes

.

- Follow the disassembly and assembly procedures in

this manual. If Huck-recommended procedures are not

followed, tool damage could result.

- Disassemble and assemble tool components in a straight

line. Do NOT bend, twist, or apply undue force. Always

apply continuous steady pressure to disassemble a

component. An arbor press provides steady pressure to

press a component into or out of an assembly.

- Never force a misaligned component. Reverse the

procedure, correct the misalignment, and start over.

FLUID MAINTENANCE

See

s

pecIfIcatIons

for fluid type. For fluid maintenance,

refer to NAS 1638 class 9, ISO CODE 18/15, or SAE level

6. Dispose of fluid in accordance with local environmental

regulations. Recycle steel, aluminum, and plastic parts in

accordance with local lawful and safe practices.

STANDARD SEALANTS, LUBRICANTS

- Apply Parker Threadmate

®

, Loctite

®

567, or Slic-Tite

®

to

male pipe threads per manufacturer’s instructions (to

ease

assembly and to prevent leaks)

.

- Smear

LUBRIPLATE

®

130-AA or

SUPER-O-LUBE

®

on

rings

and mating parts to ease assembly and to prevent

nicking/pinching rings on rough/tight spots.

POWERIG MAINTENANCE

Maintenance instructions and repair procedures are in the

appropriate Powerig Instruction Manual.

TOOL MAINTENANCE

Whenever disassembled, and at regular intervals,

depending on use, replace all O-rings and Back-up rings.

Tool-specific Spare Parts Service Kits should be kept

on hand. Inspect cylinder bore, piston, piston rod, and

unloading valve for scored surfaces, excessive wear, and

damage; replace as necessary

.

NOSE ASSEMBLY MAINTENANCE

Clean nose assemblies

in mineral spirits to clear jaws and

rinse metal chips and dirt. For a more thorough cleaning,

disassemble the nose assembly. Use a pointed “pick” to

remove embedded particles from the pull grooves of the

jaws. Clean

all parts of any assembly with UNITIZED

TM

Jaws

in mineral spirits or isopropyl alcohol only; do not let jaws

come in contact with other solvents. Do not let jaws soak;

dry them

immediately

after cleaning. Huck recommends

drying other parts before re-assembling.

Maintenance

CAUTIONS:

Consult the Material Safety Data Sheet

(MSDS) before servicing tool.

Keep foreign matter out of the hydraulic

system. Keep separated parts away from

dirty work surfaces.

Dirt and debris in hydraulic fluid causes valve

failures in tool and Powerig

®

.

Check the Assembly Drawings in this manual

for the proper direction of the flats on the

dump valve.

Do not use TEFLON

®

tape on pipe threads.

Tape can shred and break free into fluid

lines, resulting in malfunctions.

Damaged jaw teeth of a nose assembly, or

debris packed between teeth, will result

in failure of fastener installation, or faulty

fastener installation.

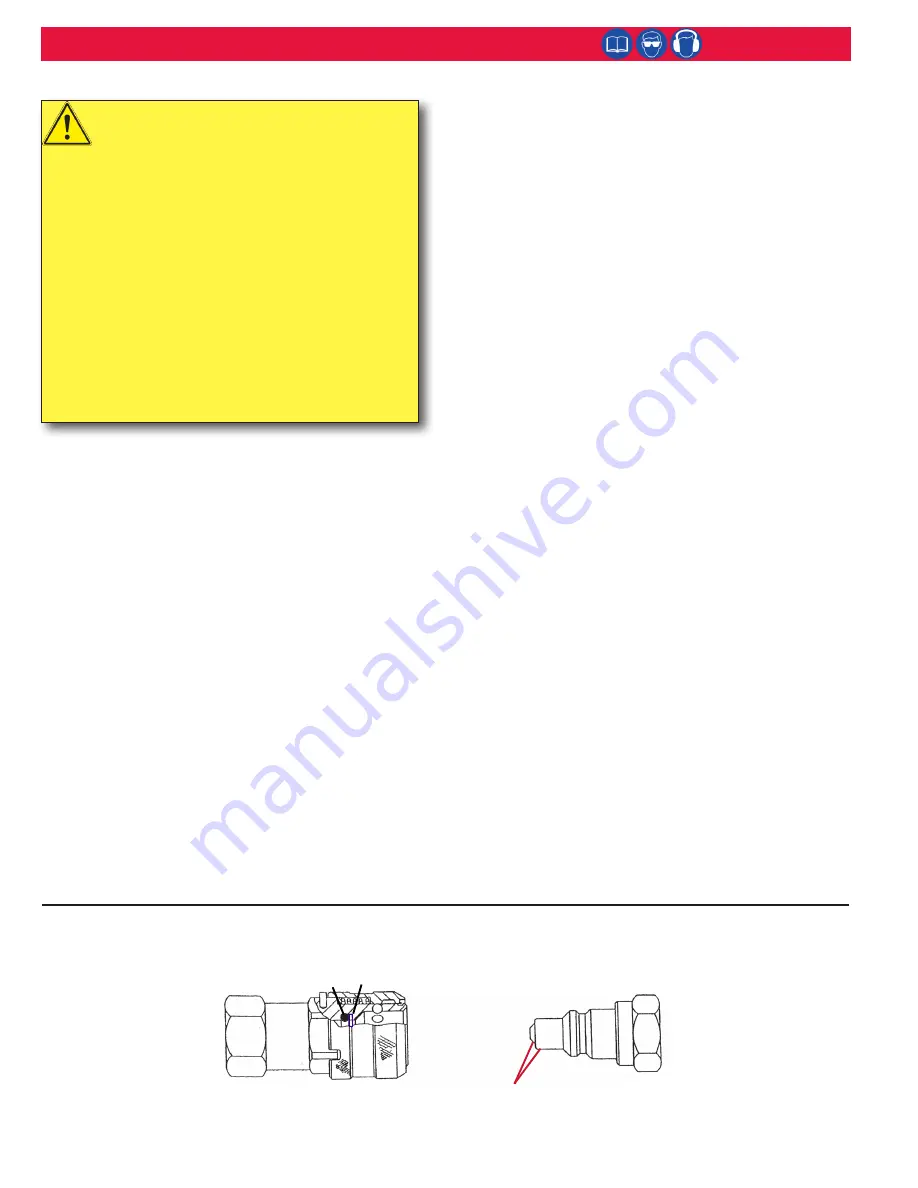

Hydraulic Couplings

504438 O-ring

501102 Back-up Ring

110439

Female

Connector

110438

Male

Connector

Use a fine India stone to remove any nicks or burrs from these

areas to prevent damage to O-ring of Female Connector.

Summary of Contents for 2580

Page 2: ...2 2580 series Hydraulic Installation Tools HK961 ...

Page 7: ...7 2580 series Hydraulic Installation Tools HK961 Assembly Drawing Main Components Figure 2 ...

Page 15: ...15 2580 series Hydraulic Installation Tools HK961 Control Cord Hose Assembly 2580 Figure 5a ...

Page 16: ...16 2580 series Hydraulic Installation Tools HK961 Sectional View A2580 Figure 5b ...

Page 18: ...18 2580 series Hydraulic Installation Tools HK961 Assembly Drawing 2580 Figure 6 ...

Page 19: ...19 2580 series Hydraulic Installation Tools HK961 Assembly Drawing A2580 Figure 7 ...

Page 20: ...20 2580 series Hydraulic Installation Tools HK961 Assembly Drawing 2580 12 Figure 8 ...

Page 21: ...21 2580 series Hydraulic Installation Tools HK961 Assembly Drawing 2580 25 Figure 9 ...

Page 22: ...22 2580 series Hydraulic Installation Tools HK961 Assembly Drawing 2580 38 Figure 10 ...