440 01 1024 01

Specifications are subject to change without notice

31

3. Do

NOT

terminate over public walkways. Avoid areas

where condensate may cause problems such as above

planters, patios, or adjacent to windows where steam may

cause fogging.

4. The vent termination shall be located at least 4

′

horizontally

from any electric meter, gas meter, gas regulator, and any

relief equipment. These distances apply

ONLY

to U.S.

installations.

5. The vent termination is to be located at least 3

′

above any

forced air inlet located within 10

′

; and at least 10

′

from a

combustion air intake of another appliance, except another

direct vent furnace intake.

6. In Canada, the

Canadian Fuel Gas Code

takes precedence

over the preceding termination instructions.

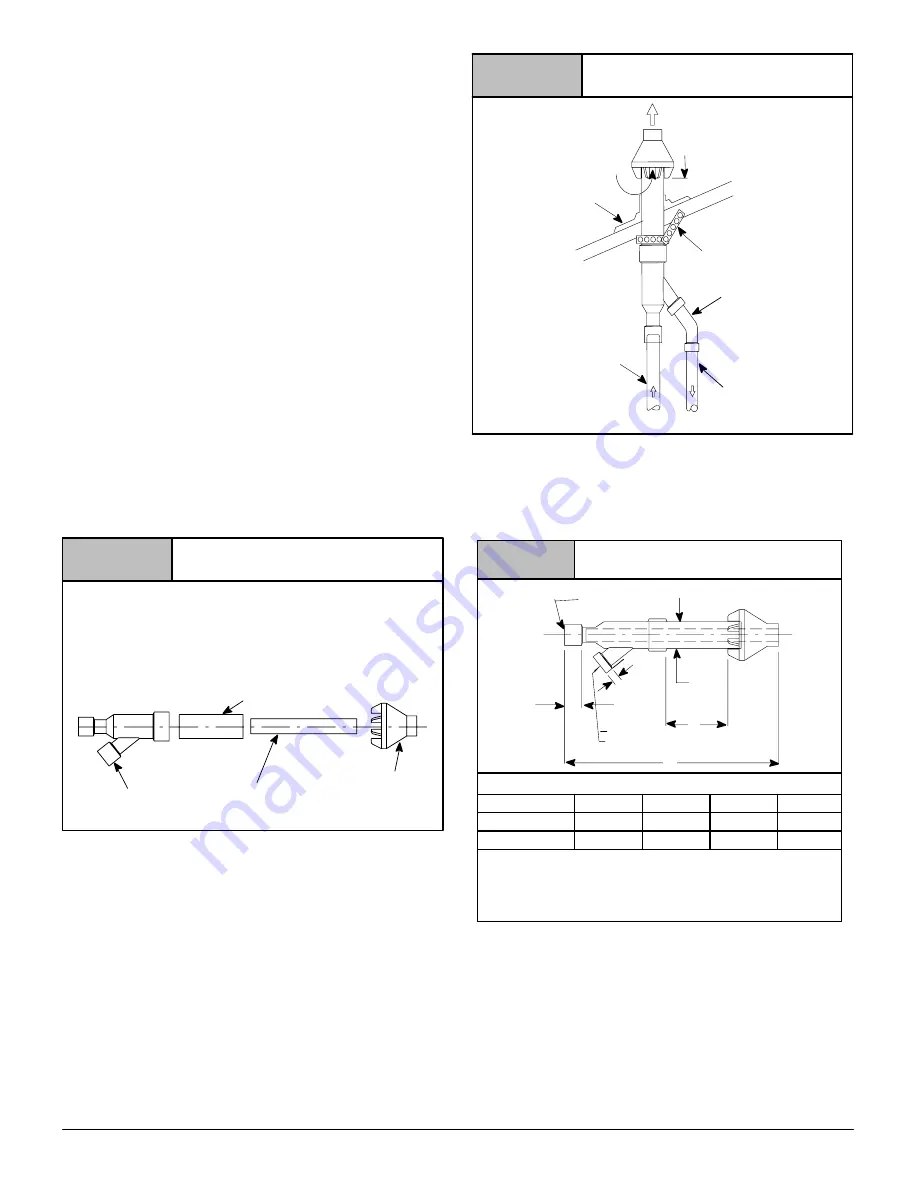

Concentric Vent Termination

Kit # N

AHA001CV & NAHA002CV

For Concentric Vent Termination information call 931.270.4100

with the complete model and serial number of the furnace.

These kits are for vertical or horizontal termination of the

combustion air inlet and the exhaust vent pipes on Category

IV

gas--fired condensing furnaces. The NAHA001CV kit can be used

for 3

″

diameter pipe systems. The NAHA002CV kit can be used

for 2

″

diameter pipe system. Refer to

Table 5

for the correct pipe

size for the furnace. Both the combustion air inlet and the exhaust

vent pipes must attach to the termination kit. The termination kit

must terminate outside the structure and must be installed per the

instructions outlined below for vertical or horizontal termination.

Vertical termination is preferred. Field supplied pipe and fittings

are required to complete the installation.

2 or 2

1

/

2

″

Dia.

SDR- 26 Pipe

Kit Components

2

″

or 3

″

Dia.

Rain Cap

Nominal 3

″

or 4

″

Dia.

SDR- 26 Pipe

2

″

or 3

″

Dia.

Y Concentric Fitting

25--22--03

Figure 31

Kit Contents:

3

″

Rain Cap or 2

″

Rain Cap

3

″

Diameter SDR--26 Pipe, 19

1

/

2

″

Long or

4

″

Diameter SDR--26 Pipe, 24

″

Long,

2

″

Diameter SDR--26 Pipe, 31

5

/

8

″

Long or

2

1

/

2

″

Diameter SDR--26 Pipe, 37

1

/

8

″

Long,

3

″

Y Concentric Fitting or 2

″

Y Concentric Fitting

Vertical & Horizontal Termination

1. Determine the pipe diameters required for the installation

from

Table 5

and

Figure 33.

2. Determine the best location for the termination kit. See

Figure 32

for vertical termination or

Figure 36

for

horizontal termination. Roof termination is preferred since it

is less susceptible to damage, has reduced intake

contaminants and less visible vent vapor. For side wall

termination, consideration should be given to: 1) possible

damage from the vapors to plants/shrubs, other equipment

and building materials, 2) possible damage to the terminal

from foreign objects, 3) wind effects that may cause

recirculation of flue products, debris or light snow and 4)

visible vent vapor.

Vent

Maintain 12

″

min. clearance above

highest anticipated snow level. Max.

of 24

″

above roof.

Combustion

Air

Roof Boot/

Flashing

(Field Supplied)

Combustion

Air

Vent

Concentric Vent Roof Installation

Support

(Field Supplied)

45

°

Elbow

(Field Supplied)

25--22--02

Note:

Support must be field installed to secure termination kit to structure.

Figure 32

3. Cut one 5

″

diameter hole through the structure for the

NAHA001CV Kit or one 4

″

diameter

hole for the

NAHA002CV Kit .

4. Dimension D may be lengthened to 60

″

max. or shortened

by cutting the pipes to 12

″

min. Dimension A will change

according to D dimension. (See

Figure 33)

Figure 33

Concentric Vent Dimensional

Drawing

25--22--03

B

PVC Intake/Combustion Air

B PVC

Vent/Exhaust

D

A

1

1

/

2

″

C

Dimensions

Model

A*

B

C

D**

NAHA001CV

38

7

/

8

3

4

1

/

2

21

1

/

8

NAHA002CV

33

3

/

8

2

3

1

/

2

16

5

/

8

* = Dimension will change accordingly as dimension D is

lengthened or shortened.

**= Dimension D may be lengthened to 60

″

may also be

shortened by cutting the pipes provided in the kit to 12

″

minimum