Appleton • 1.800.621.1506 • www.appletonelec.com

303302 Rev. G 02/16 • Page 8 of 12

Service

WARNING

Electrical power must be turned OFF before and during installation and maintenance. Failure to do so may result in serious or fatal

injuries due to electrocution.

WARNING

If any part of the receptacle appears to be missing, broken, or show signs of damage—discontinue use immediately! This condition

could cause serious or fatal personal injury due to electrocution and/or equipment damage. Repair with the proper replacement part(s)

before continuing service.

Disconnect Switch

Disconnect switches occasionally fail and need to be replaced. The disconnect switch used in this receptacle can be replaced with the

same type and brand as factory installed and will not affect the UL Listing.

To replace the disconnect switch:

1.

Referring to Figures 2 and 4, remove the switch actuating fork (Item #10) by loosening the switch actuator screws (Item #11).

2.

Loosen the line side pressure screws (Item #7) and remove the line side wires from the disconnect switch (Item #13).

3.

Remove the disconnect switch by taking out the switch mounting screws (Item #12). Remember the orientation of the “arrow” on

receptacle collar with respect to the switch position. The “arrow” must indicate that the receptacle is OFF when the disconnect

switch is in the “OFF” position.

4.

Take the disconnect switch out of the enclosure. Loosen the load side pressure screws (Item #9) and remove the load side wires.

5.

Replace the disconnect switch with the same type as shown in Table 5 and reverse the steps above. Make sure to reconnect the

wires to the same locations as before disassembly.

Table 5: Disconnect Switch

Disconnect Switch Part Number

Ampere Ratings

Number of Poles

Appleton

Leviton

Hubbell/Bryant

59501735000

MS303-DS

HBL7810D/30003D

30

3

59301608001

---

HBL7863FWD/60003FWD

60

3

6.

Torque the switch mounting screws to 20–25 in.- lb. to fasten the disconnect switch inside the enclosure (Item #5).

7.

Torque the line and load pressure screws to 25 in.- lb. for 30 A or 35 in.- lb. for 60 A to hold the wires in place.

8.

Conduct electrical tests. Refer to “Electrical Testing” on page 6 for details.

Terminal Block Interior

If applicable, tighten the terminal block lug screws to 40–45 in.-lb. torque for #6–#2 AWG wire range or 35–40 in.-lb. torque for #14–#6

AWG wire range.

WARNING

Failure to tighten the terminal block lug screws to the above torque values may result in over stressed wire terminations, which could

cause the conductors to pull out of the terminal block and cause serious/fatal injuries due to electrocution.

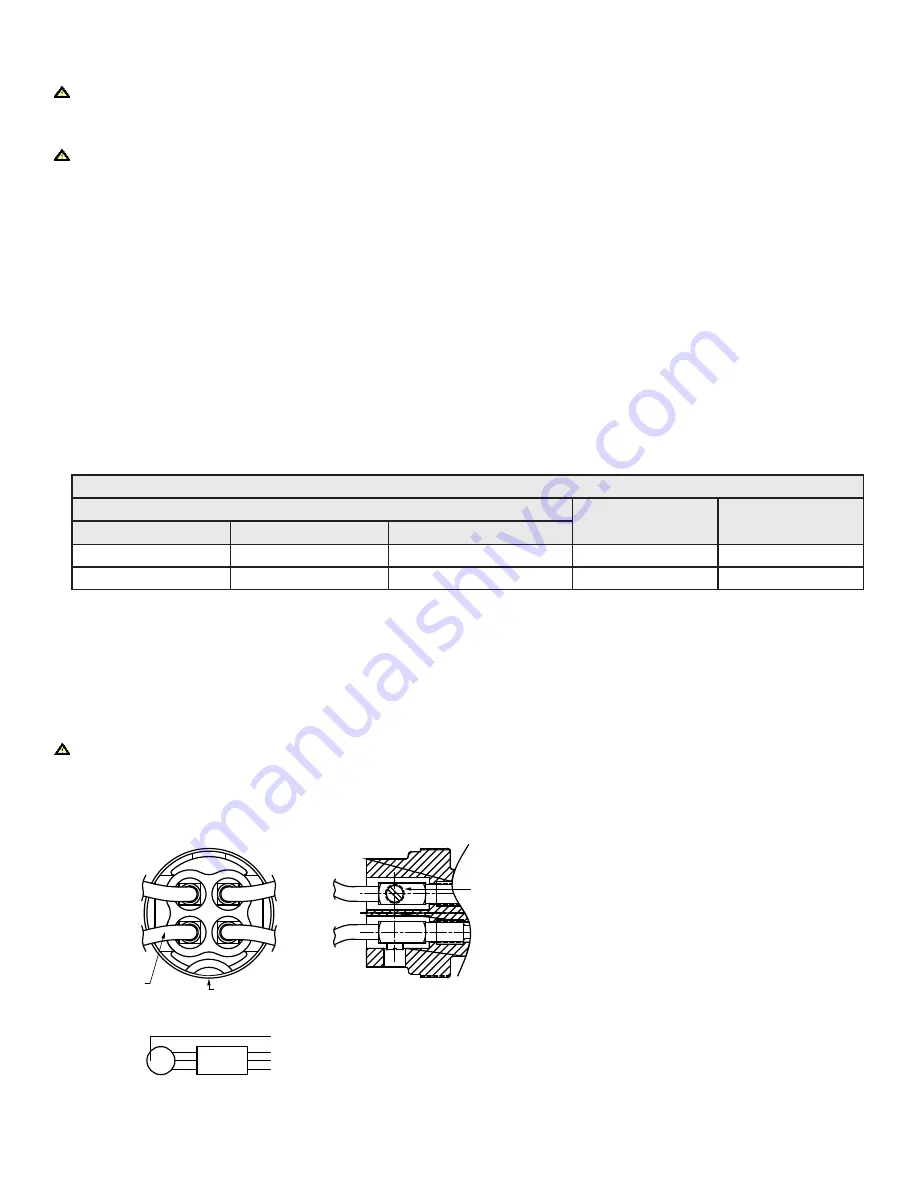

Figure 5: Receptacle Phase Designation—3 Wire, 4 Pole

G

GROUNDING WIRE

GROUNDING WIRE

1

3

2

HALF MOON

CONFIGURATION

TERMINAL BLOCK

LUG SCREW