Page 15

GENERAL

INFORMA

TION

AM

ER

IC

AN

P

ILE

DRIVING E

QU

IP

M

EN

T

J&

M

F

O

UN

DAT

ION EQ

UIP

M

EN

T

MODEL 10-4 HIH

Copyright © 2022 American Piledriving Equipment Inc. All Rights Reserved

800-248-8498

800-248-8498

WWW.AMERICANPILEDRIVING.

WWW.AMERICANPILEDRIVING.

com

com

EMERGENCY STOP:

WILL SHUT OFF

ENGINE, DISENGAGE

DRIVE AND ALL

VALVES INSTANTLY

.

Control panel will stay on.

ATTENTION:

POWER

E-STOP

Hammer Controls

Wired Pendant

IF EQUIPPED

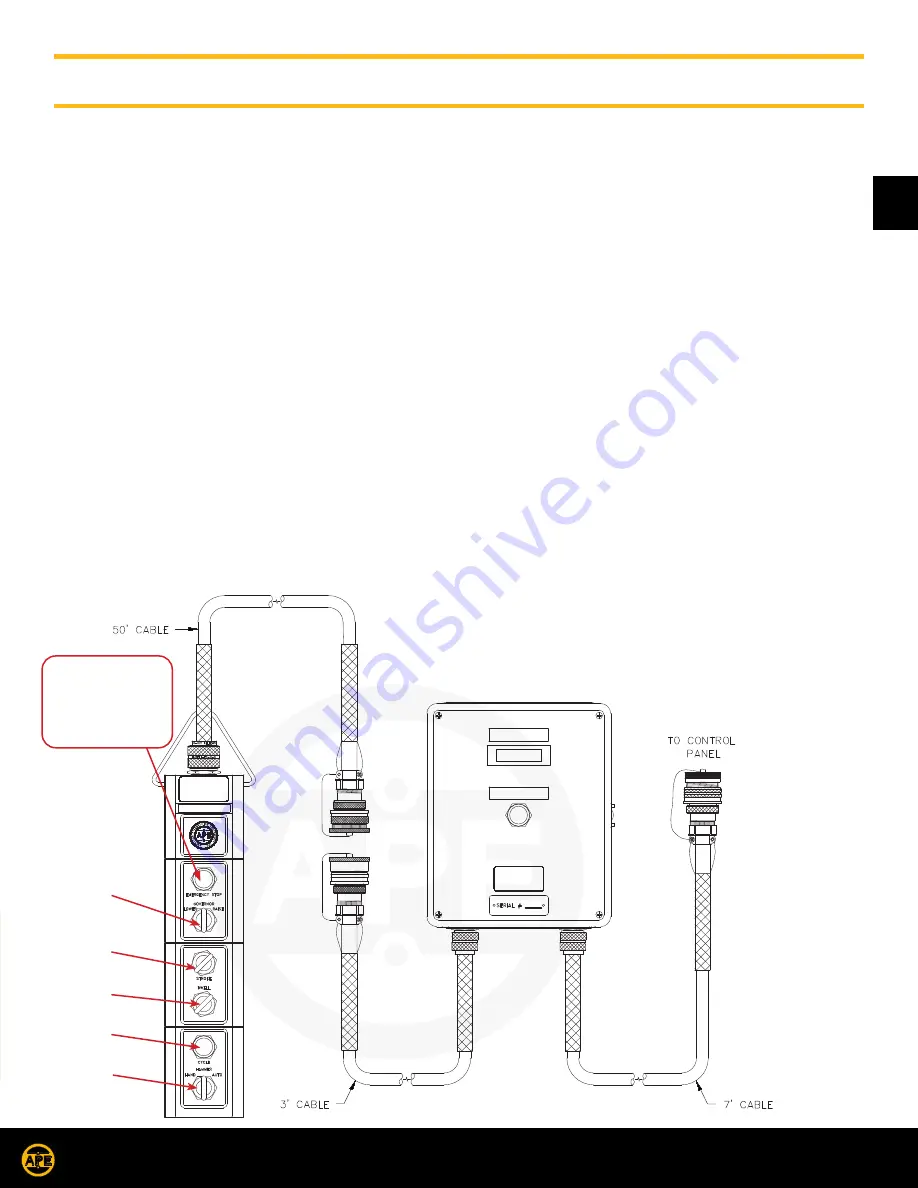

The hammer control consists of a Blow Count Box and a Pendant, connected via a multi conductor cable. The Blow Count Box should

be mounted to the Power Unit just below the Control Panel. The Blow count box is connected to the Control Panel via an Amphenol

Plug.

1. Emergency Stop Button:

The Emergency stop Button is located at the very top of the pendant station. Depressing this button will kill

the Power Unit Engine.

2. Governor Switch:

Turn this switch to the left “Lower” Engine RPM. Turn the switch to the right “Raise” Engine RPM.

Note:

If the engine rpm is increased while the hammer is operating, the stroke will increase.

3. Stroke Switch:

This switch is the primary control, regulating the time of the ram stroke. Turning the switch all the way to the “Left”

(approx 7 o’clock) will produce the shortest stroke. Turning the switch all the way to the “Right” (approx 5 o’clock) will produce

the longest stroke. Until the operator is really familiar with the hammer’s operational characteristics, the hammer should be started with

a short stroke setting, then increased after the hammer is operating.

Note:

If the engine rpm is increased while the hammer is operating, the stroke will increase.

Note:

The setting for a 4 ft drop, should be about .55 seconds.

4. Dwell Timer Switch:

It’s function is to regulate dwell time between ram impact and the beginning of the next lift cycle. Turning the

switch all the way to the “Left” (approx 7 o’clock) will produce the shortest dwell. Turning the switch all the way to the “Right”

(approx 5 o’clock) will produce the longest dwell. Until the operator is really familiar with the hammer’s operational characteristics, the

hammer should be started with a long Dwell setting, then decreased after the hammer is operating.

Note:

Allow enough time for the ram to come to rest before the lifting cycle starts again. When the dwell time is too short the ram

can be “caught” creating far to much hydraulic pressure in the cylinder. We never want to “catch” the falling ram.

5. Hammer Switch:

Turning this switch to “Hand” for intermittent stroke control. Turning this switch to the “Auto” will allow continuous use.

Note:

The engine can not be started if this switch in either Hand or Auto position. it must be in the middle “OFF” position.

6.

Cycle button:

With Hammer switch in

Hand

position pushing and holding the cycle button will raise the ram until the button is

released. When this button is released the ram will immediately fall. With the Hammer switch in the Auto position pushing the cycle

button will start and allow the hammer to run continuously. To stop the hammer turn the hammer switch to “OFF”.

The Emergency stop

Button is located at the

very top of the pendant

station. Depressing this

button will kill the Power

Unit Engine.

OPERATION / MAINTENANCE MANUAL

DASH 4 HYDRAULIC IMPACT HAMMER

7032 SOUTH 196th - KENT, WA 98032 - (800) 248-8498 / FAX (253) 872-8710

Page 4-1

Figure 4-A Blow Count Box and Pendant

Generation

Next

PLC HAMMER

RESET

BLOW COUNT

Generation

Next

IV. COMPONENT DEFINITION

IV-1. Blow Count and Pendant Layout

Governor

Stroke

Dewell

Cycle

Hand/Auto