4.10 Checking Cylinder Piston Seals

4.10.1 Power Down Models

1. First, check the lowering valve. Make sure it is operating

correctly, and the valve is not sticking or dirty. Replace

the valve if necessary. Refer to “4.7 Checking Valve

Cartridge and Solenoid” on page 12.

2. Raise the platform approximately 12 inches off of the

floor.

3. Place a floor jack securely under the platform to support

its full weight. An overhead lifting device could also be

used.

4. Raise the floor jack until the platform begins to raise

slightly.

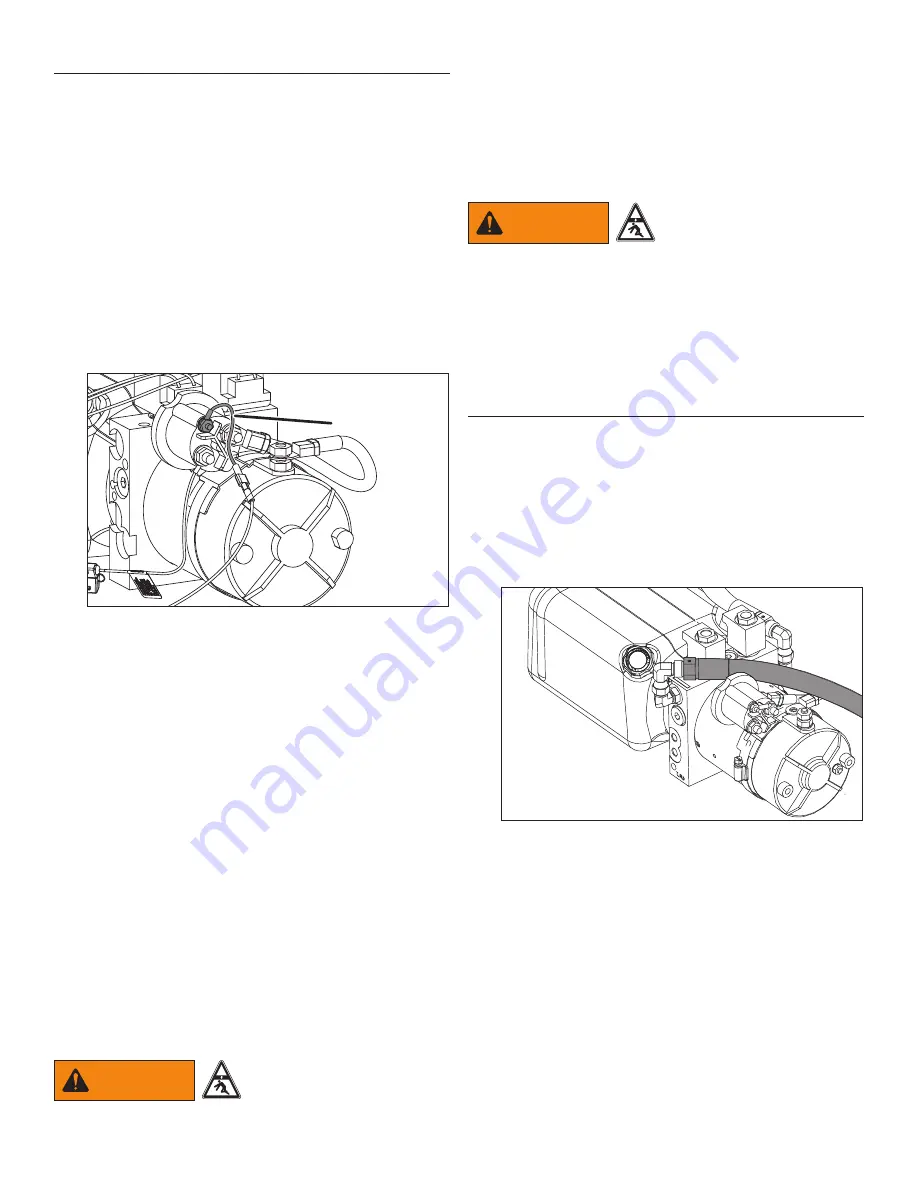

5. Disconnect the white wire from the motor start solenoid.

Place electricians tape around the end of the wire to

prevent it from making a ground connection.

White wire to

motor start

solenoid

759a

6. With the platform securely supported by the lifting

device, activate the control switch in the DOWN position

and hold the switch for 15 seconds. This will release

any pressure in the power down hose.

7. Now activate the control switch in the UP position and

hold it for 15 seconds. This will release any pressure in

the power up hose.

8. Repeat holding the control switch in the DOWN position

for 15 seconds and again in the UP position for 15

seconds. This should release any trapped pressure.

9. Carefully remove the flow control valve from the rod end

of the cylinder. Plug or cap the fitting.

10. Remove the hose from the cap end of the cylinder

and attach a temporary hose to catch any potential

leakage from the cylinder. Place the end of the hose in

a minimum one gallon container.

11. Lower the floor jack or lifting device.

12. Major seal damage will be apparent right away as

the platform would begin to slowly lower and fluid will

come out of the hose. Less extensive damage may

take longer to be seen. Allow the platform to sit for

several hours or overnight.

WARNING

Make sure nothing or no

one could accidentally go

under the platform while the

hoses are disconnected.

13. If the platform does not lower, the seals are not the

problem, most likely it is a faulty lowering valve.

14. Reconnect the white wire to the motor start termial.

Raise and lower the platform several times to remove

any trapped air.

4.10.2 Gravity Down Models

1. Completely raise the platform.

WARNING

Do not stand under the

platform.

2. Remove breather tube from the cap end of the cylinder

and attach a short piece of hose routed into a hand-

held container.

3. Activate the control switch in the UP position.

4. If oil is continuously pumped out of the hose, replace

the cylinder.

4.11 Checking System Pressure

For gravity down systems, there is only one relief valve

(power up). Power down models have two relief valve

settings; one for raising the platform (power up, upper

adjusting screw) and one for lowering the platform (power

down, lower adjusting screw).

To check the “power up” pressure setting:

1. Place the liftgate on the ground and remove the

pressure hose from the power up port of the pump.

725a

Power UP Model Pressure Hose Shown

2. Install a T-fitting (customer supplied) into the power up

port.

3. Connect a pressure gauge and reconnect the hydraulic

hose.

The pressure gauge must be rated above the maximum

pressure of the liftgate. For example, use a 4000

psi pressure gauge on a 3000 psi maximum capacity

liftgate.

4. Raise the liftgate and check the pressure on the gauge.

Summary of Contents for AC-1600

Page 2: ......