Installation of In-Line Turbulator

™

The In-Line Turbulator water circulation device is designed to

circulate the water stored in your diaphragm well tank.

1.

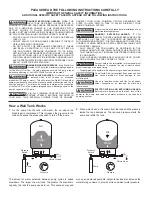

Inspect the In-Line Turbulator for any damage that may

have occurred during shipping. Insert the In-Line Turbulator

(Diagram 1) into the system connection of the expansion tank.

The Turbulator can only be inserted with the butt end out as

the locking tabs prevent it from being installed backwards.

2.

Palm press the In-Line Turbulator (Diagram 2) until the unit

locking tabs butt up against the system connection.

3.

Your diaphragm well tank is now ready to be installed

(Diagram 3).

Installation

System Connection

In-line Models:

WX-101 through WX-103: ¾" NPTM

WX-104 and WX-200: 1" NPTM

Vertical Stand Models:

WX-201 through WX-203: 1" NPTF

WX-205 through WX-350: 1¼" NPTF

Horizontal Models:

WX-102PS through WX-110PS: ¾" NPTM

WX-200PS, WX-202PS and WX-202H: 1" NPTM

Underground Models:

WX-200UG and WX-202UG: 1" NPTF

WX-250UG and WX-251UG: 1¼" NPTF

Pre Installation

The surface on which the Well-X-Trol is installed should be

capable of supporting its operating weight (including the weight

of water). The Well-X-Trol should be installed as close as

possible to the pressure switch. This will reduce the adverse

effects of added friction loss and differences in elevation

between Well-X-Trol and/or water supply main and switch.

Adjacent to pump:

This is the location chosen most often. The

Well-X-Trol tank can be used whether pumps are above or

below the surface. In either case, it protects the pump by

reducing surge, dampening pressure spikes, offering a point of

pressure control, and providing minimum run time. This location

also permits all equipment to be placed in an area that’s both

serviceable and secure.

At the end of long pipe runs:

The Well-X-Trol tank can be

positioned at the end of a long run of pipe so it can provide rapid

system response and adequate protection. When this location is

chosen, the pressure switch should either be relocated with the

Well-X-Trol tank or the setting should be adjusted to compensate

for any line pressure drop.

DO NOT LOCATE IN AN AREA WHERE

LEAKAGE OF THE TANK OR CONNECTIONS

COULD CAUSE PROPERTY DAMAGE TO THE AREA ADJACENT TO

THE APPLIANCE OR TO LOWER FLOORS.

1.

Remove protective air valve cap.

2.

Check pre-charge pressure.

3.

Release or add air as necessary to set the pre-charge

pressure 2 psig below the pressure switch pump cut-in

setting. (Example, 38 psig precharge for a 40/60 pressure.)

4.

Replace protective air valve cap.

Locking Tabs

Diagram 1.

Diagram 3.

Locking Tabs

Diagram 2.