335A-250-00

3

3/2019

Specifications Information and Repair Parts Manual

335 Series and 336 Series

x

Diaphragm Pumps

In some applications, it may be preferable to have suction/discharge

ports rotated 90 degrees to be in line with driver. If so, proceed as

follows:

a.

Remove four hex cap screws (Ref. No. A9), hex nut (Ref.

No. A13) and washers (Ref. Nos. A11 & A12) from pump

assembly to separate pump well (Ref. No. A3) from pump

base (Ref. No. A8).

b.

Rotate pump well 90 degrees clockwise so that driver is

positioned over top of discharge plate (Ref. No. W7).

c.

Be sure that pump well base and diaphragm (Ref. No. P17)

are aligned properly with one another. Then, reinstall four

hex cap screws, hex nuts and washer assemblies and

tighten.

GEAR BOX OIL

(Refer to Figure A,G)

3.

Place pump on a level surface. Fill pump gear box (Ref. No.

A1) with gear box oil before the pump is operated. Gear oil

must meet requirements of API GL-5 and military

specification MIL-L-2105B. Remove gear box housing fill

plug (Ref. No. G6). Remove level plug (Ref. No. G5). Pour

gear oil into gear box slowly until oil comes out of level plug.

Warranty on this unit is void unless the gear box is lubricated

with appropriate gear oil listed above. DO NOT OVER FILL!

INSTALLATION

NOTE:

In any installation where property damage can occur by pumps

not operating due to power outages, discharge line freezing or any

other reason, a backup system(s) and/or warning system(s) should be

used.

1.

Place the pump on a level, solid foundation, locating it as

close to the liquid as possible, making the suction line as

short and direct as possible.

2.

Install pipe nipples (Ref. No. A36) so the smoother side of

pipe end faces the suction and discharge hose.

Maximum discharge head is 25 feet or 10.9 psi. Operation over

this head or pressure will cause pump to stall and/or gearbox

damage. Use only rigid hoses.

3.

Attach suction piping to the suction inlet (Ref. No. W2) and

discharge piping to the discharge outlet (Ref. No. W7). The

suction line should be positioned such that there is a

continual upward slope from the fluid source to the pump.

Avoid using loops or sections of pipe or fittings, which might

permit air to become trapped.

NOTE:

If hose is used, be sure to use reinforced hose on both the

suction and discharge.

DO NOT USE

canvas or similar collapsible

materials.

NEVER USE PIPE REDUCER; PIPE SIZE MUST BE

EQUAL TO OR LARGER THAN PUMP PORT SIZE.

Suction line

must be airtight so that air cannot leak in and destroy priming vacuum.

On a permanent installation where piping is used, always connect a

piece of flexible hose between pump and piping so pump is free to

move slightly.

4.

It is advisable to use a strainer (Ref. No. W16) on the inlet

end of the suction hose or pipe. A properly sized strainer is

supplied with this unit and should be used at all times to

prevent damage. Keep the strainer clean. If possible,

suspend it to keep it from becoming clogged with muck,

roots, debris or leaves. It is best to keep hose free of kinks

as they will restrict flow and add excess loading to pump

and gearing.

5.

GASOLINE ENGINE UNITS:

Follow all instructions in the

engine manual before starting the engine. Fill engine with

oil, gasoline, etc.

AIR MOTOR UNITS:

Follow all instructions in the air motor

manual before starting unit.

ELECTRIC MOTOR UNITS:

It is strongly recommended

that this unit is plugged into a G.F.I. (Ground Fault

Interrupter) circuit. Consult your local electrician for

installation and availability.

6.

Input RPM (to pump)

– Input RPM must be between 1750

and 2750 RPM. Final pump speed will be 40 strokes/min.

with a 1750 RPM input and 60 strokes/min. with a 2750

RPM input.

Do not exceed 60 strokes per minute with the diaphragm pump.

OPERATION

Operate the diaphragm pump in an upright position only.

1.

This diaphragm pump is capable of priming "dry" up to

fifteen feet; it will prime much faster when it is filled with

clean water through priming cap (Ref. No. W6). Primed, it

can lift to 25 feet.

2.

Activate unit following engine or air motor manual or turning

unit on if electrical.

Do not control discharge capacity with a valve or similar device.

CLEARING JAM-UP

If large solids or an accumulation of sand or other sediment becomes

lodged in the pump well (Ref. No. A3) preventing the plunger arm

(Ref. No. A2) from making a full stroke, the pump should be

thoroughly cleaned as described in "If Pump Stalls" shown below.

Refer to parts list and illustration for parts identification.

If pump has stopped or stalled for any unknown reason, clean

out pump cavity thoroughly. Failure to comply with the "caution"

could result in damage to crank (Ref. No. P5/P9), plunger arm

(Ref. No. P1) or other parts of assembly.

1.

IF PUMP STALLS:

a.

Remove handle (Ref. No. A35).

b.

Remove four bolts (Ref. No. A9 & A10).

c.

Clean obstruction and all debris from pump well

(Ref. No. A3).

d.

Reassemble

pump

in

reverse

order

of

disassembly and return to service.

2.

IF PLUNGER ARM (Ref. No. P1) SEIZES AND GEAR BOX

OUTPUT SHAFT (Ref. No. G8) TURNS IN CRANK (Ref.

No. P5):

a.

Remove sheet metal guard (Ref. No. A4) by

loosening hand knob screws (Ref. No. A5).

b.

Disassemble pump and clean as described in

steps (a) through (d) listed for stalled engine jam

up.

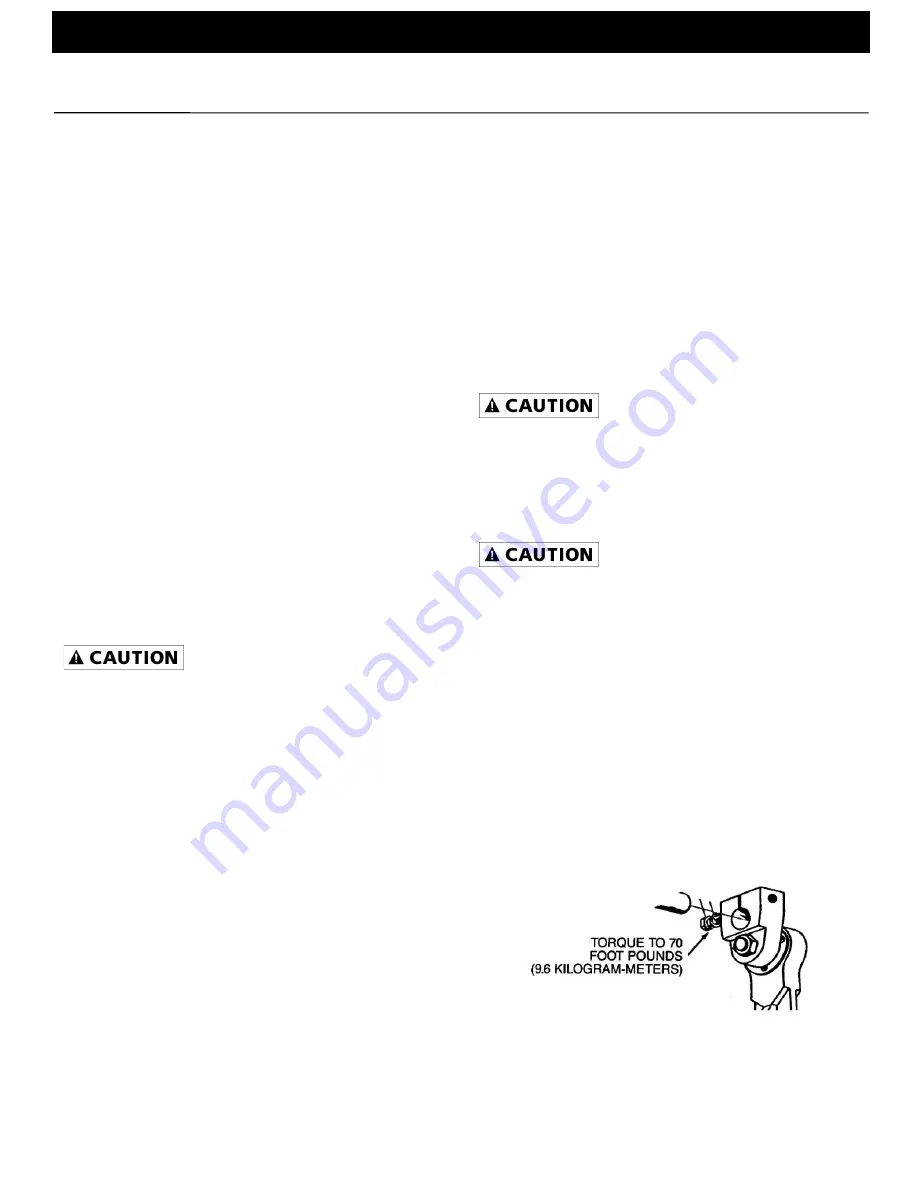

c.

Torque the crank lock screw (Ref. No. P6) to 70

foot pounds with an appropriate torque wrench

(see Figure 3).

Figure 3

d.

Reassemble the pump in reverse order of

disassembly and return to service.