Temposonics

®

R-Series

V

POWERLINK

Operation Manual

I 15 I

4.4 Installation and design of Temposonics

®

RFV

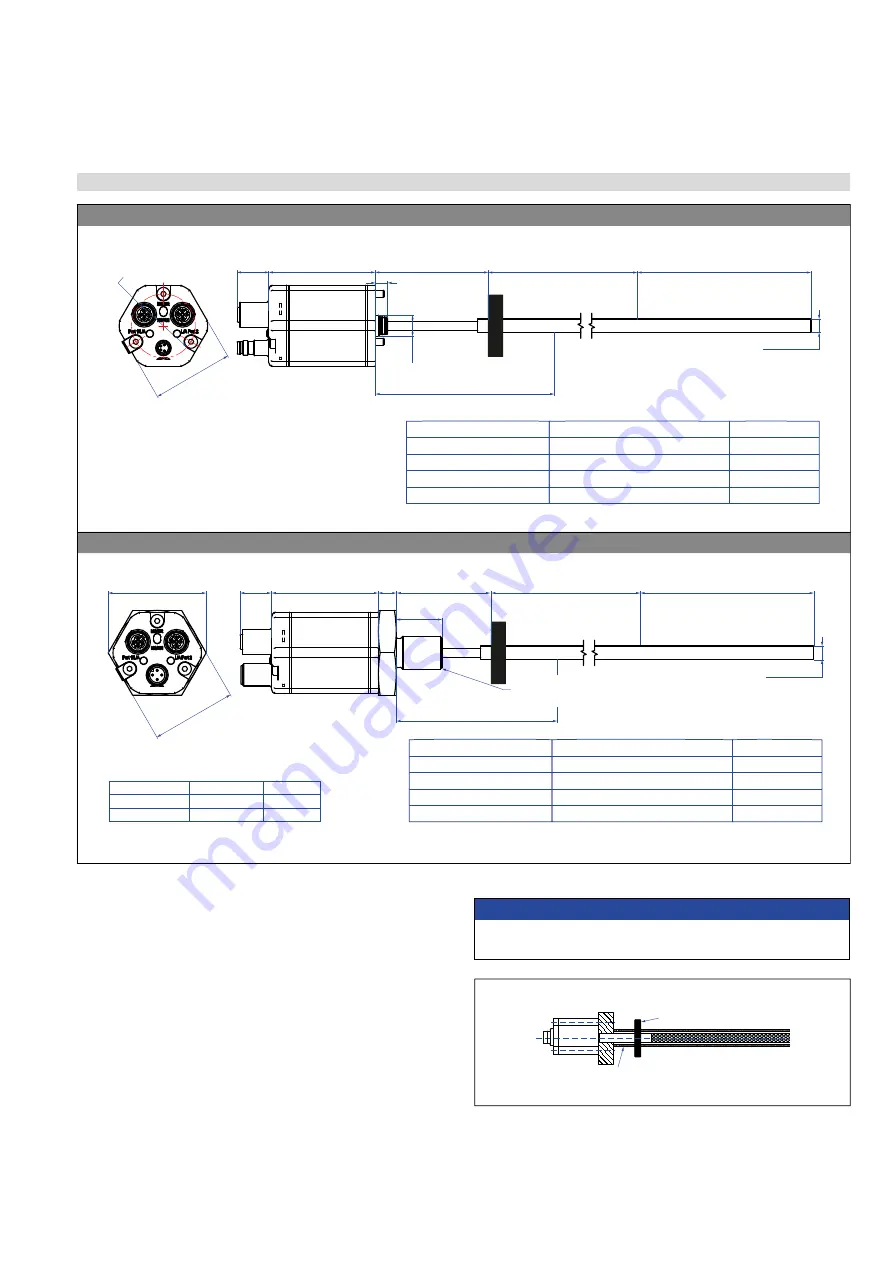

Fig. 12: Temposonics

®

RFV with ring magnet

Fig. 13: Sensor with support tube

Installation of RFV

Note the following information when mounting and handling an RFV

sensor:

1. Always insert the flexible sensor rod in a support tube (e.g.

pressure rod HD/HL/HP or HFP profile). The support tube has

to be made of non-magnetic material and has to have an inside

diameter of minimum 9.4 mm (0.37 in.) (Fig. 13). The support

tube can be straight or bent.

2. Do never bend beyond the minimum bending radius of 250 mm

(9.84 in.).

3. Note the minimum distance to a spatial limitation of 300 mm

(11.81 in.), when mounting/dismounting the sensor. The

recommended distance is 500 mm (20 in.) (Fig. 15).

4. Note the non-flexible area of the sensor rod from the flange of

107 mm (4.21 in.) (for RFV-B) respectively 97 mm (3.82 in.) (for

RFV-M/-S).

NOTICE

Smaller radiuses < 250 mm (9.84 in.) cause damage to the flexible

sensor rod.

Position magnet

Non-magnetic support tube, inside Ø 9.4 (0.37)

Linear measurement

RFV-B – RFV base unit, example: Connection type D56 (connector outlet)

Magnet

Null zone

61

(2.4)

Dead zone

see table

17

(0.67)

7

(0.28)

11.4

(0.45)

Not flexible

107 (4.2)

Stroke length

150…20,000

(6…787)

Ø 8 ±0.23

(Ø 0.31±0.01)

Sensor electronics housing

58

(2.28)

Tolerance of total length

Dead zone

Stroke length

Up to 7620 mm (300.00 in.)

Up to 10,000 mm (393.70 in.)

Up to 15,000 mm (590.55 in.)

Up to 20,000 mm (787.00 in.)

+8 mm (0.31 in.)/−5 mm (0.20 in.)

+15 mm (0.59 in.)/−15 mm (0.59 in.)

+15 mm (0.59 in.)/−30 mm (1.18 in.)

+15 mm (0.59 in.)/−45 mm (1.77 in.)

94 mm (3.70 in.)

100 mm (3.94 in.)

120 mm (4.72 in.)

140 mm (5.51 in.)

Note:

Tolerance of total length has no influence on the stroke length.

44

(1.7)

Ø 34.6

(Ø

1.36)

RFV-M/-S – RFV with threaded fl ange M18×1.5-6g or ¾"-16 UNF-3A, example: Connection type D58 (connector outlet)

Magnet

Null zone

51

(2)

Dead zone

see table

10

17

(0.67)

b

Not flexible

97 (3.82)

Stroke length

150…20,000

(6…787)

Ø 8 ±0.23

(Ø 0.31 ±0.01)

Threaded flange

»M«

:

M18×1.5-6g

Threaded flange

»S«

:

¾"-16 UNF-3A

Sensor electronics housing

58

(2.28)

Tolerance of total length

Dead zone

Stroke length

Up to 7620 mm (300.00 in.)

Up to 10,000 mm (393.70 in.)

Up to 15,000 mm (590.55 in.)

Up to 20,000 mm (787.00 in.)

+8 mm (0.31 in.)/−5 mm (0.20 in.)

+15 mm (0.59 in.)/−15 mm (0.59 in.)

+15 mm (0.59 in.)/−30 mm (1.18 in.)

+15 mm (0.59 in.)/−45 mm (1.77 in.)

94 mm (3.70 in.)

100 mm (3.94 in.)

120 mm (4.72 in.)

140 mm (5.51 in.)

Note:

Tolerance of total length has no influence on the stroke length.

a

Threaded flange

»M«

»S«

a b

A/F 46 (1.81) 53

(2.09)

A/F 44.5 (1.75) 51.3 (2.02)

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Controlling design dimensions are in millimeters and measurements in ( ) are in inches