910101-001048

12/2019

Page 15 of 42

Media Filling Process

Before filling the vessel, please follow these steps:

•

Visually inspect the inside of the vessel to ensure all

the media retaining nozzles are present and fixed in

place.

•

When performing this inspection:

o

Ensure that you are wearing the correct PPE.

o

Locate the top flange – see fig. A.

o

Now carefully remove the bolts on the top flange.

This will release the blind flange and gasket. Care

should be taken not to damage the flange, flange

gasket, or drop the bolts inside the vessel.

o

Carefully remove the flange and internal pipe-work,

which has the Dual Vortex Generator attached. This

will expose the nozzles for inspection. Make sure all

nozzles are in place.

o

If any nozzles are missing, please contact Amiad

Water Systems before proceeding further.

DO NOT FILL THE VESSEL IF NOZZLES ARE MISSING.

Make sure vessel interior is free from any debris

before following the media filling procedure below.

•

It is strongly recommended to use correct PPE during

media installation. (See media data sheets which can

be found on the bags, and further in this document).

o

First ensure that the valves on the backwash inlet

V3 and process outlet V2 are closed.

o

Now, via the top flange, fill half the vessel with clean, fresh water. This is to ensure no damage occurs to the

backwash nozzles located within the vessel base.

o

Load the base media in the correct order (beginning with the largest size first – i.e. Grade 3) with the applicable

quantities, as shown in the Media Data table below. The depth guide is in mm and given as a guideline only.

o

Level each layer before moving on to the next layer.

o

Once the loading is complete, the media should be within approximately 20mm of the base of the vortex

generator. Check this with the length of the vortex inlet pipe as you are filling the vessel to avoid overfilling.

o

Place the top flange with the gasket back onto the vessel in the same orientation as it was removed,

remembering to securely screw the feed pipe via union.

•

The media bags are marked for the grade size.

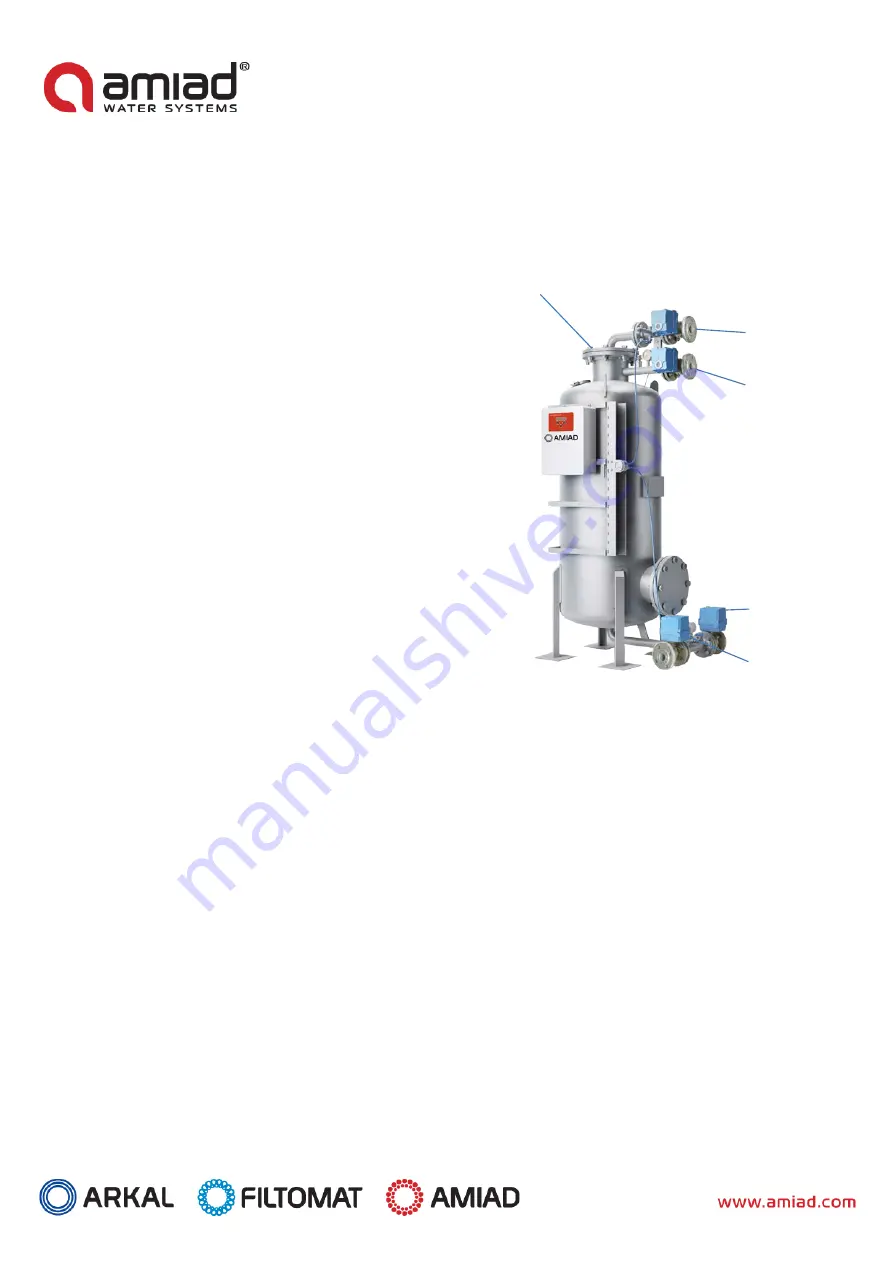

Fig. A.

Top

Flange

V1

Process Inlet

Valve

V4

Backwash

Outlet Valve

V3

Backwash

Inlet Valve

V2

Process

Outlet Valve

Summary of Contents for DVF

Page 20: ...910101 001048 12 2019 Page 20 of 42 DVF Filter P ID Drawing ...

Page 21: ...910101 001048 12 2019 Page 21 of 42 DVF 300 Filter GA Drawing ...

Page 22: ...910101 001048 12 2019 Page 22 of 42 DVF 300 Filter Parts Drawing ...

Page 24: ...910101 001048 12 2019 Page 24 of 42 DVF 600 Filter GA Drawing ...

Page 25: ...910101 001048 12 2019 Page 25 of 42 DVF 600 Filter Parts Drawing ...

Page 27: ...910101 001048 12 2019 Page 27 of 42 DVF 900 Filter GA Drawing ...

Page 28: ...910101 001048 12 2019 Page 28 of 42 DVF 900 Filter Parts Drawing ...

Page 30: ...910101 001048 12 2019 Page 30 of 42 DVF 1200 Filter GA Drawing ...

Page 31: ...910101 001048 12 2019 Page 31 of 42 DVF 1200 Filter Parts Drawing ...

Page 35: ...910101 001048 12 2019 Page 35 of 42 Annex A Media Safety Data Sheet 7 pages ...

Page 36: ...910101 001048 12 2019 Page 36 of 42 ...

Page 37: ...910101 001048 12 2019 Page 37 of 42 ...

Page 38: ...910101 001048 12 2019 Page 38 of 42 ...

Page 39: ...910101 001048 12 2019 Page 39 of 42 ...

Page 40: ...910101 001048 12 2019 Page 40 of 42 ...