113335 - 12

www.amdry.com

17

Type of Gas

Manifold Pressure

*

In-Line Pressure

Natural

3.5 in

wc

6.0 - 12.0 in wc

8.7 mb

14.92 - 29.9 mb

Liquid

Propane

10.5 in wc

11.0 in wc

26.1 mb

27.4 mb

Technical Gas Data

Gas Specifications

Shaded areas are stated in metric equivalents

* Measured at outlet side of gas valve pressure tap when gas valve is on.

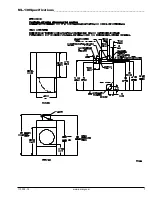

Gas Connections:

Inlet connection ............... 1” N.P.T.

Inlet supply size ............... 1” diameter pipe (minimum)

Btu/hr input (per dryer) .... 375,000 (94,500 kcal/hr)

Natural Gas

Regulation is controlled by the dryer’s gas valve’s internal

regulator. Incoming supply pressure must be consistent

between a minimum of 6.0 in wc (14.92 mb) and a maximum

of 12.0 in wc (29.9 mb) pressure.

L.P. Gas

Dryers made for use with L.P. gas have the gas valve’s internal

pressure regulator blocked open so that the gas pressure

must be regulated upstream of the dryer. The pressure

measured at each gas valve pressure tap must be a

consistent 10.5 in wc (26.1 mb). There is no regulator or

regulation provided in an L.P. dryer. The water column

pressure must be regulated at the source (L.P. tank) or an

external regulator must be added to each dryer.

Shaded area is stated in metric equivalent

* D.M.S. equivalents are as follows:

Natural Gas ........................... #4 = 0.2090” (5.3086 mm).

L.P. Gas ................................ #30 = 0.1285” (3.2639 mm).

Shaded area is stated in metric equivalent

* D.M.S. equivalents are as follows:

Natural Gas ........................... #12 = 0.1890” (4.8006 mm).

L.P. Gas ................................ #33 = 0.1130” (2.8702 mm).

ML-130

TYPE OF GAS

Btu/hr

Rating

kcal/hr

Rating

Natural

Liquid Propane

Qty.

D.M.S.

*

Part No.

Qty.

D.M.S.

*

Part No.

375,000

94,500

3

#4

140832

3

#30

140819

Liquid Propane Conversion Kit Part Number 881868

Piping/Connections

All components/materials must conform to National Fuel Gas

Code Specifications ANSI Z223.1-LATEST EDITION, or in

Canada, CAN/CGA-B149.1-M91 (Natural Gas) or CAN/CGA-

B149.2-M91 (L.P. Gas) or LATEST EDITION (for General

Installation and Gas Plumbing), as well as local codes and

ordinances and must be done by a qualified professional. It

is important that gas pressure regulators meet applicable

pressure requirements, and that gas meters be rated for the

total amount of all the appliance Btu being supplied.

The dryer is provided with a 1” N.P.T. inlet pipe connection

extending out the back area of the burner box. The minimum

pipe size connection (supply line) to the dryer is 1” diameter.

For ease of servicing, the gas supply line of each dryer must

have its own shutoff valve.

The size of the main gas supply line (header) will vary

depending on the distance this line travels from the gas meter

or, in the case of L.P. gas, the supply tank, other gas-operated

appliances on the same supply line, etc. Specific information

regarding supply line size should be determined by the gas

supplier.

NOTE: Undersized gas supply piping can create a low or

inconsistent pressure, which will result in erratic operation

of the burner ignition system.

Consistent gas pressure is essential at all gas connections.

It is recommended that a 1-inch (2.54 cm) pipe gas loop be

installed in the supply line servicing a bank of dryers. An

in-line pressure regulator must be installed in the gas supply

line (header) if the (natural) gas pressure exceeds 12.0 in

wc (29.9 mb) pressure.

IMPORTANT: A water column pressure of 3.5 in wc (8.7

mb) for natural gas and 10.5 in wc (26.1 mb) for L.P. dryers

is required at the gas valve pressure tap of each dryer for

proper and safe operation.

A 1/8” N.P.T. plugged tap, accessible for a test gauge

connection, must be installed in the main gas supply line

immediately upstream of each dryer.

IMPORTANT: Pipe joint compounds that resist the action

of natural and L.P. gases must be used.

Test all connections for leaks by brushing on a soapy

water solution (liquid detergent works well).

ML-130DR

TYPE OF GAS

Btu/hr

Rating

kcal/hr

Rating

Natural

Liquid Propane

Qty.

D.M.S.

*

Part No.

Qty.

D.M.S.

*

Part No.

300,000

75,600

3

#12

140863

3

#33

140855

Liquid Propane Conversion Kit Part Number 882626

Never test for leaks with a flame!!!

▲

WARNING

!

IMPORTANT: The dryer and its individual shutoff valve

must be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.5 kPa).