11

Ducting - General

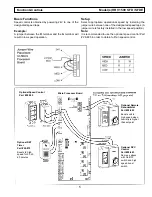

Drains

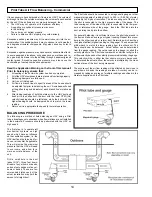

Connect the drain pans in the bottom of the HRV to a drain

line fastened to the holes provided. Create a “P” trap to

prevent odors from being drawn through. Make sure the

drain line slopes down to drain properly and if this is not

possible a condensate pump will be required for removal

of the water. Note that stagnant water is a leading cause of

indoor air quality problems; confirm drainage after installa-

tion by pouring water into trays. Drain line must be installed

where it will not freeze.

The Ductwork System

A well designed ducting system will allow the HRV to oper-

ate at its maximum efficiency. Avoid the use of undersized

ducting and sharp radius bends and tees which can signifi-

cantly increase the system pressure drop and reduce the

air flows.

NOTE: Fully insulated ducting with an integral vapor bar-

rier must be used on all runs passing through un-

heated areas in order to avoid condensation prob-

lems and energy losses from the air streams.

* Consult local Codes

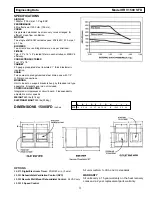

To minimize pressure drop and noise, galvanized metal

ducts sized for 1200 fpm (6.09 m/s) (maximum velocity)

are recommended. Keep ducting as short as possible and

use a minimum of elbows and tees. Connecting sections

and shorter runs may be flexible ducting one size larger

than the metal duct. Use flexible duct connectors at the

HRV to avoid noise transmission. All duct joints must be

secured with screws, rivets or duct sealant and sealed with

aluminum duct tape to prevent leakage.

Outside Weatherhoods

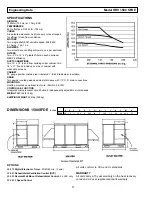

The HRV 1500 SFDE is shipped with 2 weatherhoods inside

the cabinet which attach to the outer ends of the cabinet

using bolts provided. The HRV 1500 SFD requires exterior

hoods to be provided by the contractor.

NOTE: It is extremely important to design and install the

fresh air intake in an area where the hoods will

gather the freshest air, free from restriction.

Recommended:

•

No less than 10 ft. (3 m) apart from each other, or per

local code restriction.

•

At least 18 in. (46 cm) above ground level.

•

Away from sources of contaminants, such as automobile

exhaust fumes, gas meters, garbage containers, cooling

towers, etc.

•

Not exposed to prevailing winds, whenever reasonably

possible.

The outside perimeter of the weatherhood must be caulked

to prevent leakage into the building. The design and size

of the weatherhoods or louvers chosen by the installer must

allow for adequate free area. Water and snow penetration

of the system is minimized when the airflow does not ex-

ceed 750 FPM (3.81m/s) free area velocity.

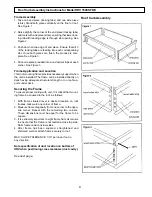

Ducting from the Weatherhoods

Galvanized sheet metal ducting with sufficient cross sec-

tion with an integral single piece vapor barrier should be

used to connect the HRV to the weatherhoods. All ducting

must meet ULC Class 1 Fire Rating. A minimum R value of

insulation should be equal to 4 (RSI 0.75), or as stated in

local codes. A good bead of high quality caulking (prefer-

ably acoustical sealant) and taping with a high quality alu-

minum foil tape is recommended to seal the duct to both

the HRV and the weatherhood.

Warmside Ducting - General

Ducting from the HRV to different areas within the building

should be galvanized metal whenever possible. To mini-

mize airflow losses in the ductwork system, all ducts should

be as short as possible and with as few bends or elbows as

possible. 45° elbows are preferred to 90° elbows, when-

ever possible. Use Y tees instead of 90° tees whenever

possible. All duct joints must be fastened securely and

wrapped with a quality duct tape to prevent leakage. We

recommend aluminum foil tape.

Summary of Contents for 1500 SFDE

Page 10: ...10 Roof Curb Detail for Model HRV 1500 SFDE ...

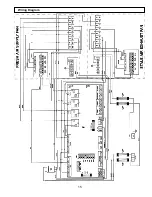

Page 15: ...15 Wiring Diagram ...