Cleaning, maintenance and repair

12.16

Field sprayer calibration

Test the field sprayer by carrying out calibration

•

before the start of the season.

•

each time a nozzle is changed.

•

to check the setting information in the spray tables.

•

in the case of deviations between the actual and required

spray rate [l/ha].

Any deviations between the actual and required spray rate [l/ha] may

be caused by:

•

the difference between the actual operational speed and that

indicated on the tractor meter and/or

•

natural wear to the spraying nozzles.

Calibration equipment:

(1) Quick-check beaker

(2) Stopwatch

Determining the actual spray rate while stationary via the individual nozzle output

Determine the nozzle output from at least 3 different nozzles. To do

this, check one nozzle on the left boom, one on the right boom and

one in the middle of the sprayer boom as described below.

1. Determine the precise spray rate [l/ha] required for the crop pro-

tection measure.

2. Determine the required spray pressure.

3. Control terminal /

AMASPRAY

+

:

3.1 Enter the required spray rate into the operating terminal.

3.2 Enter the permissible spray pressure range for the spraying

nozzles fitted to the sprayer boom on the operating termi-

nal.

3.3 Switch the operating terminal from AUTOMATIC mode over

to the MANUAL mode.

4. Fill the spray liquid tank with water.

5. Switch on the agitator.

6. Manually set the required spray pressure.

7. Switch on spraying and check that all nozzles are functioning

perfectly.

8. Calculate the individual nozzle output [l/min] at several nozzles.

To do so, hold the quick-check beaker under a nozzle for pre-

cisely 30 seconds.

9. Switch off spraying.

10. Calculate the average individual nozzle output [l/ha].

•

Using the table on the quick-check beaker.

•

By calculation.

•

Using the spray table.

228

BAG0021.14 05.19

Summary of Contents for UG 2200 Special

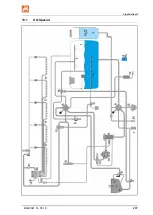

Page 237: ...Liquid circuit 13 1 UG Special BAG0021 14 05 19 237 ...

Page 238: ...Liquid circuit 13 2 UG Super 238 BAG0021 14 05 19 ...

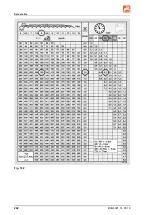

Page 242: ...Spray table Fig 182 242 BAG0021 14 05 19 ...

Page 251: ...Spray table BAG0021 14 05 19 251 ...

Page 252: ......