E N

E X P L A N A T I O N O F S Y M B O L S

4

1

Explanation of Symbols

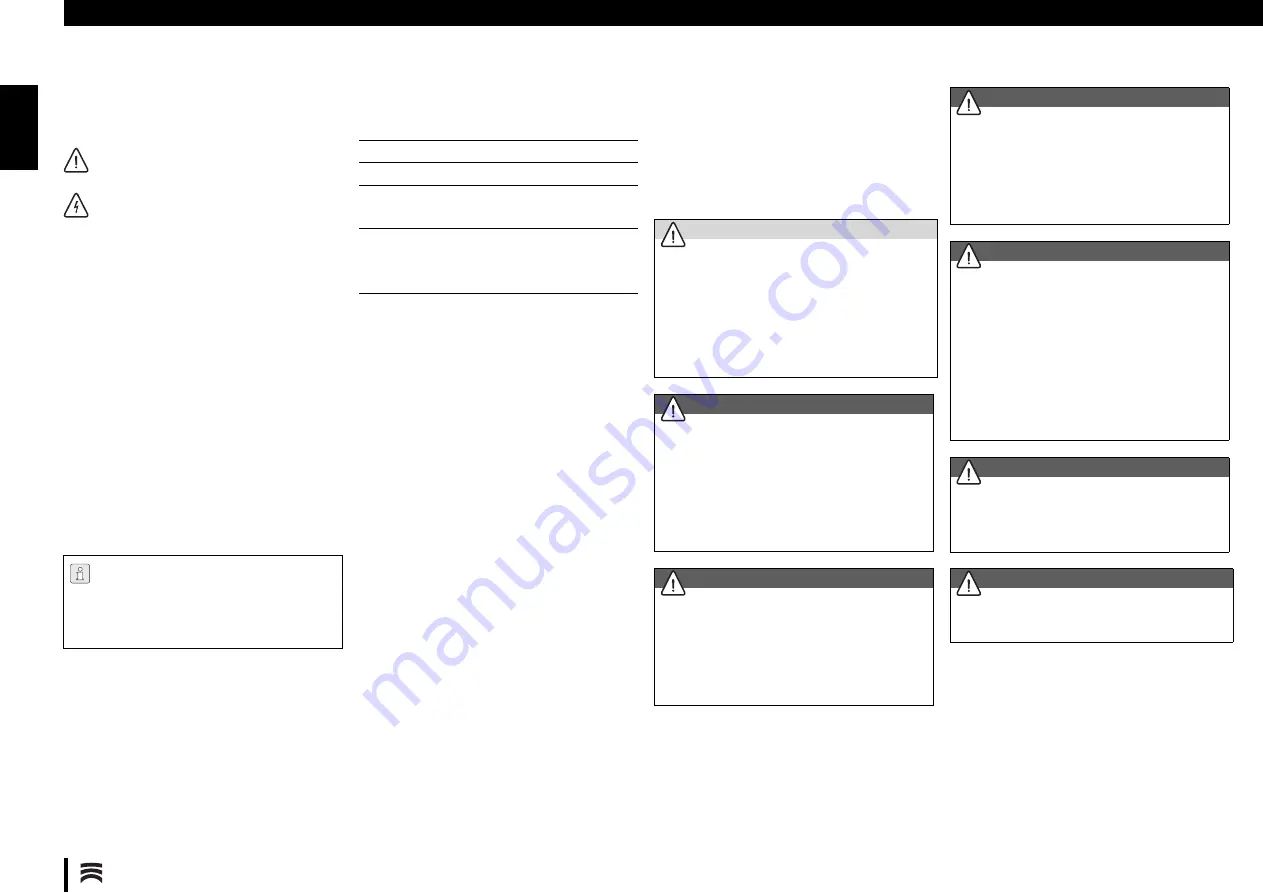

Warning indications

Warning indications in the text are

marked with a triangle and boxed.

In case of hazards through electricity,

the exclamation mark in the warning tri-

angle is substituted by a lightning bolt.

Signal words at the beginning of a warning

indication specify the type and severity of the

consequences, if the measures to avert the

hazard are not adhered to.

_

NOTE

means that property damage can

occur.

_

CAUTION

means that light to fairly serious

personal injury can occur.

_

WARNING

means that serious personal

injury can occur.

_

DANGER

means that life-threatening per-

sonal injury can occur.

Important information

Other symbols in the Manual

2

General Maintenance

and Cleaning Instruc-

tions

When installing, starting-up and operating the

machine, always observe the following safety

instructions:

Important information that does not

lead to hazards for humans or property

damage are marked with the icon aside

and are also boxed.

Symbol

Meaning

▷

Item of an operation description

_

Item of a list

▪

Subitem of an operation descrip-

tion or a list

[3]

Numbers in square brackets refer

to position numbers in graphs/fig-

ures

CAUTION:

A defective machine can lead to malfunctions!

On detection of damage or a functional defect

of the machine:

▷

Label the machine as defective.

▷

Prevent further operation until the

machine is repaired.

NOTE:

Possible damage to the glass window!

Zirconia dust is abrasive and can cause

scratches in glass.

▷

Clean the window in the door carefully,

using only a soft cloth; do not scrub or

scour.

NOTE:

Possible damage to the milling chamber!

Cleaning agents can aggressive to the inner

walls of the milling chamber.

▷

Clean the milling chamber with water only.

▷

Do not use cleaning agents.

NOTE:

Possible machine damage through dried-in

coolant/lubricant and bound in milling dust.

After wet processing:

▷

Clean and dry the milling chamber prior to

downtimes lasting several hours.

NOTE:

Possible machine damage due to unsuitable

cleaning agents!

▷

Clean the milling chamber and material

store only with the specified cleaning aids

(brush, cleaning cloth).

▷

Do not use sponges, brushes etc.

▷

Do not use compressed air, ultrasonic or a

steam jet for the cleaning!

NOTE:

Insufficient milling results!

▷

Keep the zero-point clamping system

clean at all times.

NOTE:

The machine may only be serviced by trained

specialised personnel.