#859 Operation & Care Manual • 2.

held, it is necessary to periodically use a pocket

thermometer to check each item to make certain the correct

temperatures are being maintained. Proper temperature

range is between 150° and 160°F (66° and 71°C). Normally,

this will require a thermostat setting of between number

“6” and “8,” although a higher or lower setting may

sometimes be required. The full service unit always

requires a higher setting.

6. SERVE FRESH HOT FOOD

Keep foods looking fresh. Occasionally stir or rotate foods as

needed. Serve products in the proper heat tested package or

container. Keep merchandiser doors closed after serving.

Wipe spills immediately to assure maximum eye appeal, and

to ease end of the day cleanup.

The cleanliness and appearance of this unit will

contribute considerably to operating efficiency

and savory, appetizing food. Good equipment

that is kept clean works better and lasts longer.

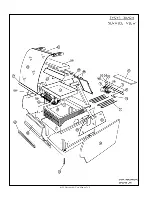

THOROUGHLY CLEAN THE MERCHANDISER

DAILY

1.

Turn lights and adjustable thermostat to the “

OFF

”

position. Disconnect unit from the power source.

2.

Remove, cover or wrap, and store unused products

under refrigeration.

3.

Remove all detachable items such as pan separator bars,

pans, baskets, etc. Clean these items separately.

4.

Clean the interior metal surfaces with a damp cloth

and any good alkaline or alkaline chlorinated based

commercial detergent or grease solvent at the

recommended strength. Use a plastic scouring pad

or an approved oven cleaner for difficult areas.

Avoid the use of abrasive cleaning compounds,

chloride based cleaners, or cleaners containing

quaternary salts. Rinse carefully to remove all residue and

wipe dry. Clean glass with a window cleaner.

NOTE:

Never use hydrochloric acid (muriatic acid) on stainless steel.

5.

To help maintain the protective film coating on polished

stainless steel, clean the exterior of the unit with a cleaner

recommended for stainless steel surfaces. Spray the

cleaning agent on a clean cloth and wipe with the grain of

the stainless steel.

Always follow appropriate state or local health (hygiene)

regulations regarding all applicable cleaning and sanitation

requirements for equipment.

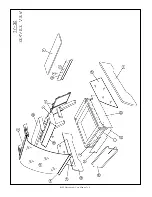

PAN CONFIGURATIONS

TY-30, TYSYS-30, TY-30/RM, TYSYS-30/RM

NOTE:

ADDITIONAL PAN

SEPARATOR BARS MAY

BE REQUIRED TO

ACCOMMODATE MAXIMUM

CAPACITIES.

A

A

A

A

A

A

A

A

A

A

A

A

AA

AA

AA

AA

AA

AA

AAA

AAA

AAA

AAAA

AAAA

ONE-HALF

SIZE PAN

ONE-HALF

SIZE PAN

TWO-THIRDS

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

2 PAN

ZONES

O

n

e

(1

) F

U

L

L

-S

IZ

E

P

A

N

a

n

d

O

n

e (

1

) O

N

E-

THI

RD SI

ZE PAN per

pan zone.

—

U

p

t

o

2 Ful

l-S

iz

e Pans w

ith

2 O

n

e-

Thi

rd Si

ze Pans

Two (

2

) ONE-

HALF SI

ZE PANS a

n

d

O

n

e (

1

) O

N

E-

THI

R

D SI

ZE PAN per

pan zone.

—

U

p

t

o

4 O

n

e-

H

a

lf Si

ze Pans w

ith

2 O

ne-

Thi

rd Si

ze Pans

One

(

1

) TW

O-

THI

R

DS SI

ZE PAN a

n

d

Tw

o (

2

) O

N

E-

THI

RD SI

ZE PANS per

pan zone.

—

Four

(

4

) O

N

E-

THI

RD SI

ZE PANS per

pan zone.

—

U

p t

o 8 O

ne-

Thi

rd Si

ze Pans per

m

er

c

handi

ser

U

p

t

o

2 Tw

o-

Thi

rds Si

ze Pans w

ith

4 O

ne-

Thi

rd Si

ze Pans

AA

AA

AA

AA

AA

AA

AAA

FULL-SIZE

PAN

ONE-THIRD

SIZE PAN

A

A

A

A

A

A

AAA

AAA

AAA

AAA

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

Pan Separator Bars

Full-size (long)...............

11317

3 needed (center & both sides)

Half-size/Third-size........

11318

At no time should the inside or outside of

the unit be washed down, flooded with

water or liquid solution. Do not use

water jet to clean. NEVER STEAM

CLEAN. Severe damage or electrical

hazard could result, voiding the

warranty.

Always disconnect unit from

power source before cleaning

or servicing.

C A R E a n d C L E A N I N G

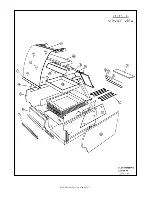

H o o d g l a s s ex t e n d e d t o t h e f u l l u p r i g h t

p o s i t i o n i s s t a b i l i z e d t h r o u g h t h e u s e

o f g a s s t r u t s d e s i g n e d f o r t h e f u l l

l o a d b e a r i n g w e i g h t .

T h e s e s t r u t s

c o u l d w e a k e n o r f a i l d u e t o w e a r,

e nv i r o n m e n t a l c o n d i t i o n s o r a g i n g .

Operators should be aware of any decrease in effort to lift

the hood and initiate an immediate gas strut safety check.

D O N OT L I F T T H E H O O D I N T H I S C O N D I T I O N .

!

C A U T I O N

Summary of Contents for TY-30

Page 7: ... 859 Operation Care Manual 6 ...

Page 8: ... 859 Operation Care Manual 7 ...

Page 10: ... 859 Operation Care Manual 9 ...

Page 11: ... 859 Operation Care Manual 10 ...

Page 12: ... 859 Operation Care Manual 11 ...

Page 13: ... 859 Operation Care Manual 12 ...

Page 14: ... 859 Operation Care Manual 13 ...

Page 15: ... 859 Operation Care Manual 14 ...

Page 16: ... 859 Operation Care Manual 15 ...