Page 13 of 18

506762-03

Issue 1946

Start-Up

If unit is equipped with a crankcase heater, it should

be energized 24 hours before unit start-up to prevent

compressor damage as a result of slugging.

CAUTION

1. Rotate fan to check for frozen bearings or binding.

2.

Inspect all factory and field-installed wiring for loose

connections.

3. After evacuation is complete, open liquid line and

suction line service valves to release refrigerant

charge (contained in outdoor unit) into system.

4.

Replace the stem caps and secure finger tight, then

tighten an additional 1/6 of a turn.

5. Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit

nameplate. If not, do not start equipment until the

power company has been consulted and the voltage

condition corrected.

6. Set thermostat for cooling demand, turn on power to

indoor blower, and close the outdoor unit disconnect

switch to start the unit.

7. Recheck unit voltage with unit running. Power must be

within range shown on unit nameplate.

Refrigerant Charging

Excessive amounts of liquid refrigerant entering the

suction line can damage the compressor. When adding

refrigerant, precautions must be taken to control the

flow of liquid into the system. This can be done by using

a liquid vaporizing adapter or manual control using a

sight glass as indicator.

CAUTION

Units are factory charged with the amount of R-410A

refrigerant indicated on the unit rating plate. This charge is

based on a matching indoor coil and outdoor coil with 15’

line set. For varying lengths of line set, refer to Table 4 for

refrigerant charge adjustment. A blank space is provided

on the unit rating plate to list the actual field charge.

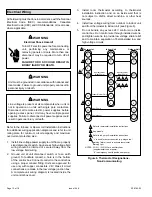

Table 4. Refrigerant Charge Adjustment

Liquid Line Set Diameter

Oz. Per 5 ft. adjust from 15

ft. line set*

3/8 in.

3 oz. per 5 ft.

or 0.6 oz. per 1 ft.

* If line length is greater than 15 ft., add this amount. If line

length is less than 15 ft., remove this amount.

Mineral oils are not compatible with R-410A. If oil must

be added, it must be a polyolester oil.

IMPORTANT

NOTE:

Both airflow and refrigerant charge must be

monitored for proper system set-up. It may be necessary to

alternately check and adjust the airflow and the refrigerant

charge.

If the system is void of refrigerant, or if the outdoor ambient

temperature is cool, use the weigh-in method to charge the

unit. Do this after any leaks have been repaired.

1. Recover the refrigerant from the unit.

2. Conduct a leak check, then evacuate as previously

outlined.

3. Weigh in the charge according to the total amount

shown on the unit nameplate.

If weighing facilities are not available or if unit is being

charged during warm weather, use one of the following

procedures.

• For systems using a TXV on the indoor evaporator

and outdoor temperature above 60°F

– charge in

cooling mode using the subcooling method and table

provided on the unit access panel.

• For systems below 60°F

– charge in heating mode

using the subcooling method and table provided on

the unit access panel. Attach low pressure gauge

hose to auxiliary service port to access suction side in

heating mode.

NOTE:

All unit table values are based on 70 to 80°F

indoor return air temperature for cooling mode, and

65

°

F to 75°F return air temperature for heat mode.