801805

87

Section 5 Service Procedures

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

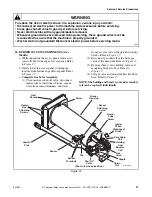

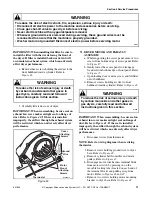

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect all electric power to the machine and accessories before servicing.

• Close gas shut-off valve to gas dryer before servicing.

• Never start machine with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the machine is properly grounded.

• Washer motor not grounded! Disconnect electric power before servicing motor.

W502

WARNING

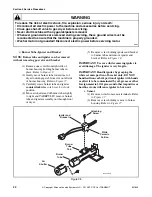

65. BURNER SYSTEM COMPONENTS (Gas

Models)

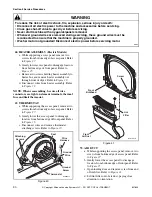

a. While supporting the access panel, remove two

screws from bottom edge of access panel. Refer

to Figure 27.

b. Gently lower the access panel to disengage

locators from bottom edge of front panel. Refer

to Figure 35.

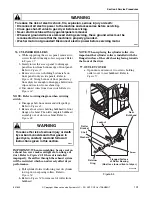

c. Complete Gas Valve Assembly.

(1) Close main gas shut-off valve, disconnect

igniter wires at disconnect blocks, sensor

wires from sensor terminals, and wires

from gas valve coils at the quick disconnect

blocks. Refer to Figure 37.

(2) Disconnect gas shut-off valve from gas

valve at the union nut. Refer to Figure 37.

(3) Remove three screws holding valve and

mounting bracket to base. Refer to

Figure 37.

(4) Lift gas valve and mounting bracket from

base. Refer to Figure 37.

NOTE: The holding and booster coil, and secondary

coil can be replaced individually.

Figure 37

Sensor

Lead-In

Pipe

Heater

Box

Attaching

Screws

Heat

Shroud

Sensor

Terminals

Tab

Union

Nut

Nipple

Gas

Valve

Holding

And

Booster

Coil

Secondary

Coil

Igniter

Wires

Disconnect

Block

Burner

Tube

Screw

Burner

Housing

Sensor

Attaching

Screw

Screw

Shut-Off

Valve

(Shown in closed position)

D241SE3G