801805

109

Section 6 Adjustments

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect all electric power to the machine and accessories before servicing.

• Close gas shut-off valve to gas dryer before servicing.

• Never start machine with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the machine is properly grounded.

• Washer motor not grounded! Disconnect electric power before servicing motor.

W502

WARNING

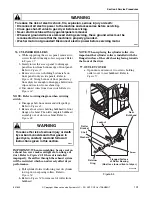

82. WASHER MOTOR BELT TENSION

NOTE: Belt adjustment procedures are done

through front of washer, however, as an option,

washer can be moved from its location and belt

adjustment can be done through lower access panel

opening on rear panel.

a. While supporting lower front access panel,

remove two screws from bottom edge of access

panel and remove panel. Refer to Figure 8.

b. Working through the access door opening,

place a locking pliers on the metal rod and

loosen the two adjusting bolts. Refer to

Figure 60. Repeat procedure to loosen the two

pivot bolts. Refer to Figure 60.

c. Pull down on motor to increase belt tension.

Use a Burroughs belt gauge to obtain proper

tension. Proper belt tension is obtained when

belt can be deflected approximately 1/4 inch

(6.35 mm) from normal position when

moderate pressure 50 to 60 pounds (22.68 to

27.22 Kg) is applied to a point midway between

pulleys. Refer to Figure 60.

d. After proper belt tension has been obtained,

tighten belt adjusting bolts firmly, then tighten

pivot bolts. Refer to Figure 60.

Figure 60

SWD1676S

Inner

Basket

Pulley

Pivot

Bolt

Adjusting

Bolt

1/4 Inch

Motor

Pulley

Belt

Metal

Rod

Adjusting

Bolt

Wire

Harness

Pivot

Bolt

Motor

Mounting

Bracket