Installation

11

803447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

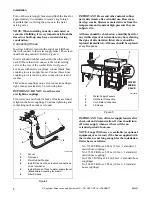

Step 5: Remove the Shock Sleeves and

Shipping Brace

Remove front access panel by removing the two screws

at the bottom of the panel.

Remove the five bolts and lockwashers from shipping

brace with a wrench and remove brace. Refer to

Figure 10

. Four bolts are located on the washer base

and one is holding the brace to the weight. Remove all

four shock sleeves by pulling on the yellow rope.

Remove label from front side of front access panel and

place on backside of front access panel for future

reference.

NOTE: The shipping brace, bolts, washers and

shock sleeves should be saved and MUST be

reinstalled whenever the washer is moved more

than 1.22 m (4 feet). Refer to

User-Maintenance

section for instructions. Do not lift or transport

washer from front or without shipping materials

installed.

Store the shipping materials in the bag provided in the

accessories bag. Save materials for use whenever the

washer is moved.

Reinstall front access panel.

IMPORTANT: DO NOT tip washer more than

152.4 mm (6 inches) in any direction after shipping

brace has been removed. Shock absorbers may

separate and damage to washer may result. For

leveling purposes, the washer may be tilted a

maximum of 152.4 mm (6 inches) in any direction.

Figure 10

Step 6: Wipe Out Inside of Wash Drum

Before using washer for the first time, use an all-purpose

cleaner, or a detergent and water solution, and a damp

cloth to remove shipping dust from inside wash drum.

Figure 11

FLW2124N

1

Shock Sleeves

2

Motor Mount

3

Hooked End of Shipping Brace

4

Bolts and Lockwashers

FLW2124N

2

1

4

3

FLW2135N

FLW2135N