366

Rockwell Automation Publication 2198-UM004A-EN-P - October 2019

Chapter 12

Motion Control Applications

When the electronic cam is operating, if you want to change the slave axis speed or cam

phase, you can use the PR position increment command. The cam phase alignment

function and macro application of the rotary shear are used to correct the phase position

of the slave axis.

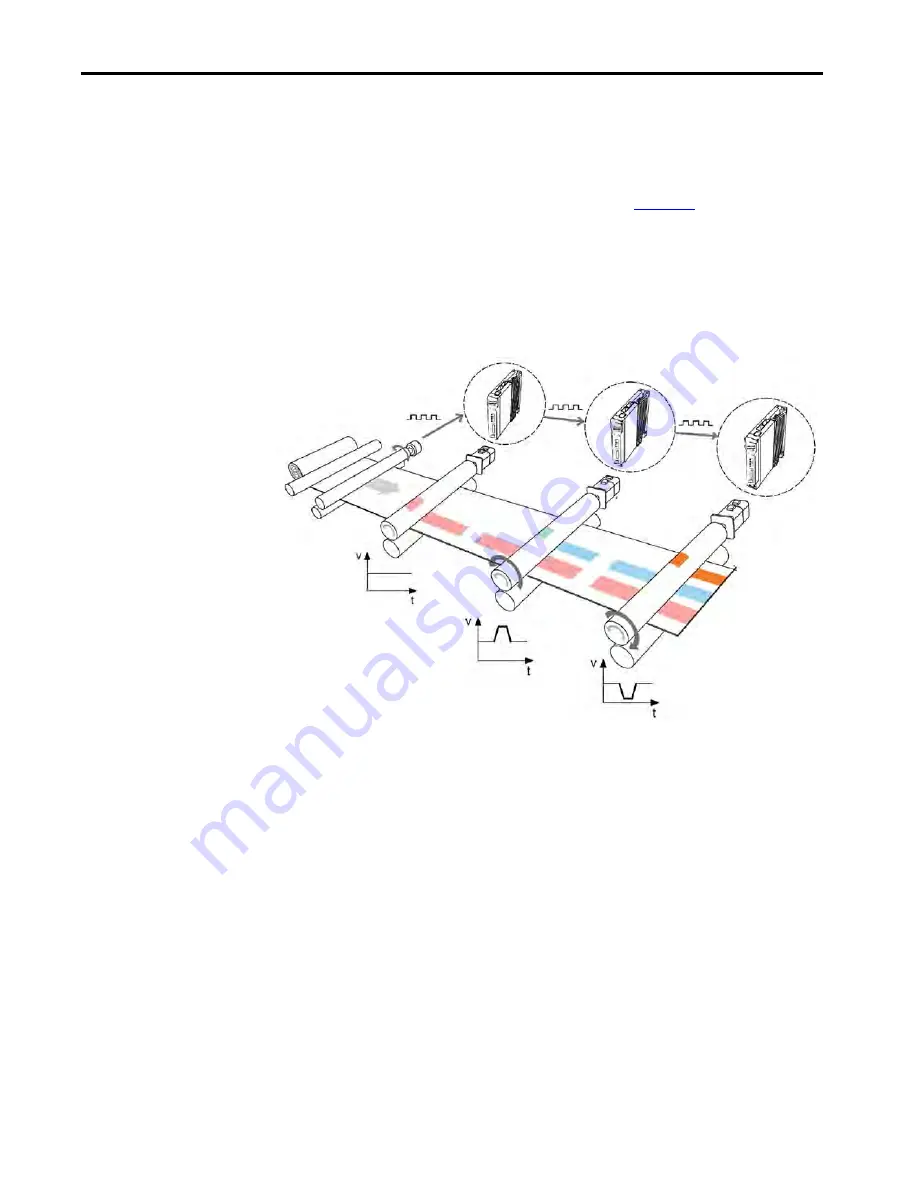

Taking the three-axis synchronous printing machine in

feeding axis is used as the master axis. The master axis pulse signals are transmitted to the

three slave axes whose E-Cam curve are the same. In general, the phases of these three

servo drives must be the same. If phases differ during the application, you can use this

phase correction function to perform the cam phase alignment. Generate a positive offset

phase by setting the forward incremental command and generate a reverse offset phase by

setting the reverse incremental command.

Figure 187 - E-Cam Phase Correction

E-Cam Troubleshooting

If the E-Cam does not work properly, you can check the following points for

detection:

• Control Mode — Make sure that the control mode is PR mode and the

servo drive is actually activated (Servo On).

• Pulse Source of Master Axis — Make sure that the pulse source of the

master axis (ID376 (P5.088.Y)) is set properly. The count of the number

of master axis pulses can be read by ID374 (P5.086)

ECamMasterAxisPosition or by monitor variable 059. When the input is

from terminal I/O connector, the count of the pulse command can be

observed by ID310 (P5.018) PulseCmdPosition. When the input is from

MFB terminal connector, the count of the auxiliary encoder pulses can be

observed by ID309 (P5.017) AuxEncoderPosition.

Summary of Contents for Kinetix 5100 2198-E1004-ERS

Page 499: ......