2

Rockwell Automation Publication 800G-IN005A-EN-P - May 2018

Bulletin 800G Assembled Stations

Use in areas other than those areas specified or the modification of the

product by anyone other than the manufacturer is not permitted and

exempts Rockwell Automation from liability for defects and any

further liability.

The applicable statutory rules and other binding directives that relate

to workplace safety, accident prevention, and environmental

protection must be observed.

Before you commission or restart operation, check compliance with all

applicable laws and directives.

All enclosures, front-of-panel operators, and back-of-panel modules

can be used only if they are in a clean, undamaged condition. Do not

modify these components in any way.

Standards Conformed To

Assemble, Install, and Commission

• Only qualified personnel are allowed to assemble, disassemble,

install, and commission the device.

• Protect devices against mechanical damage or electrostatic

discharge.

• Use suitable tools for installation. Do not modify the

assembled station or components in any way.

• Use cable that is rated with an appropriate temperature range

suitable for the application.

• IEC/EN 60079-17 must be observed.

Installation and Removal

Protective Earthing Components

For metal cable glands, follow these steps:

1. Position the earth plate

where the metal cable

gland is installed (top

or bottom).

2. Install the earth plate

between the rib and

inside wall of the

enclosure.

3. Open the terminal cages of the earth plate and insert the

conductors.

4. Tighten the earth plate terminals to a torque range of

0.7…1.0 N·m (6…9 lb·in).

For plastic cable glands, follow these steps:

\

1. Position the earth

bracket where the

plastic cable gland is

installed (top or

bottom).

2. Install the earth

bracket between the

rib and inside wall of

the enclosure.

3. Open the terminal cages of the earth bracket and insert the

conductors.

4. Tighten the earth bracket terminals to a torque range of

0.7…1.0 N·m (6…9 lb·in).

Contact Blocks and Power Modules

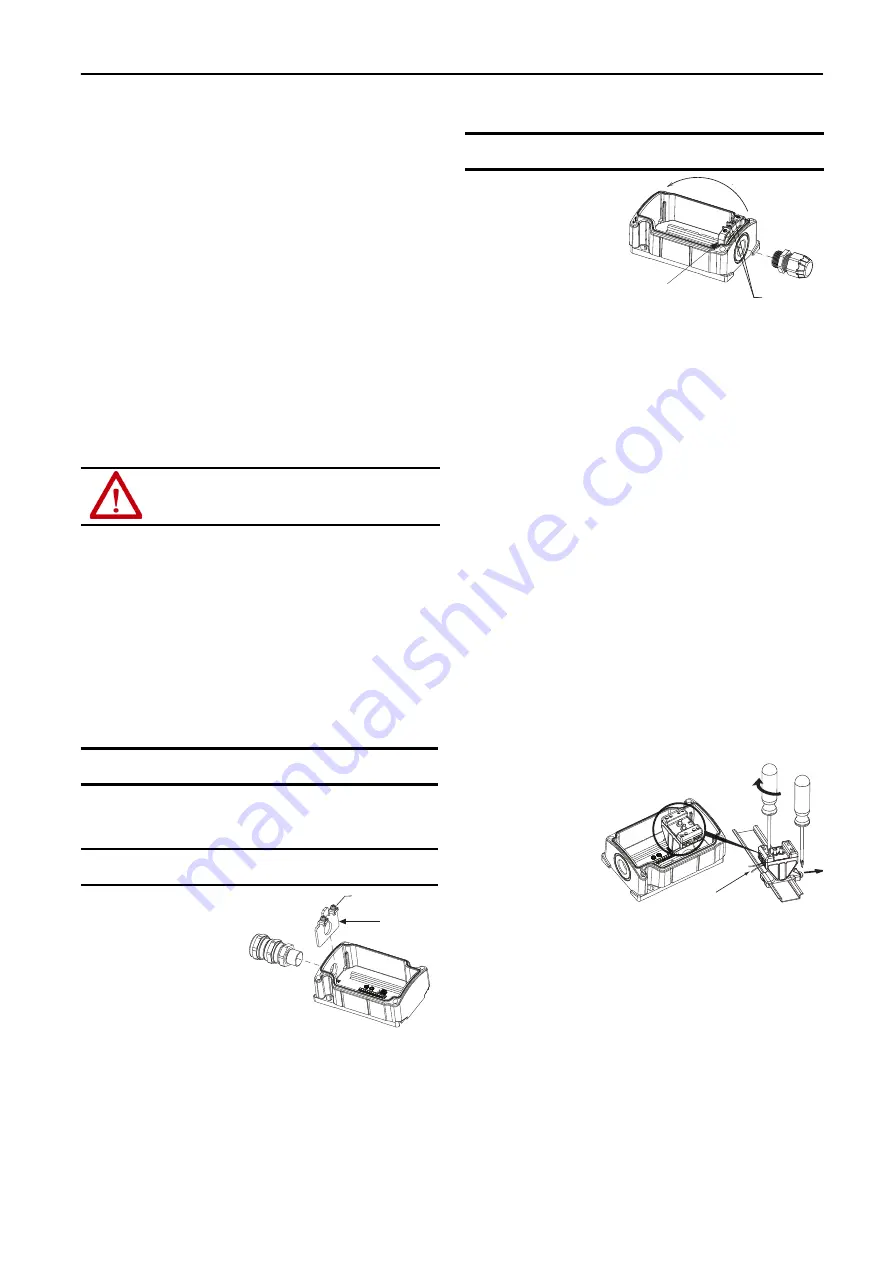

To install contact blocks and power modules, follow these steps:

1. Align the notch of the component with the cut-out in the

enclosure rail.

2. Snap the contact block or power module onto the rail of the

enclosure.

3. Check that the component is secured to the enclosure rail.

To remove contact blocks and power modules, follow these steps:

1. Position a screwdriver inside of the black tab at the base of the

component.

2. Gently pull the black tab in a direction away from the

enclosure rail.

3. Lift up on the component to remove it from the enclosure rail.

Wiring Contact Blocks and Power Modules

Take care when following these steps to connect cable to contact blocks

or power modules:

1. Strip 40 mm

(1.575 in.) of

sheath off the

cable.

2. Remove

approximately

6 mm (.236 in.)

of insulation

from the

conductors.

3. Prepare the ends of the fine-stranded and multi-stranded

conductors. Crimp wire end sleeves with a suitable crimp tool.

Suitable connection cross-sections are 0.75…2.5 mm2

(18…14 AWG).

4. Open terminal cage and insert conductors.

5. Tighten the terminals to a torque range of 0.4…0.7 N·m

(3.5…6.2 lb·in).

• EN 60079-0

• EN 60079-1

• EN 60079-7

• EN 60079-31

• IEC 60079-0

• IEC 60079-1

• IEC 60079-7

• IEC 60079-31

ATTENTION:

Risk of serious injury due to incorrect assembly,

installation, and commissioning.

IMPORTANT

The assembled stations that are pictured serve as an example

for all assembled station configurations.

IMPORTANT

An earth plate must be used for grounding enclosures with a

metal cable gland.

0.7…1.0 N·m

(6…9 lb·in)

Earth Plate

(800G-AEP

x

)

IMPORTANT

An earth bracket must be used for grounding enclosures with

a plastic cable gland.

0.7…1.0 N·m

(6…9 lb·in)

Earth Bracket

(800G-AEB)

0.75…2.5 mm²

(18…14 AWG)

Contact Block/Power Module

(800G-XB

x

-EX, 800G-DB

x

-EX,

and 800G-DB

x

X

x

-EX)

0.4…0.7 N·m

(4…6 lb·in)