Troubleshooting

25

4. Protect the paint spray system when storing it (e.g. in the original packaging or in

a box) if you do not use it regularly or will not be using it over an extended period.

Troubleshooting

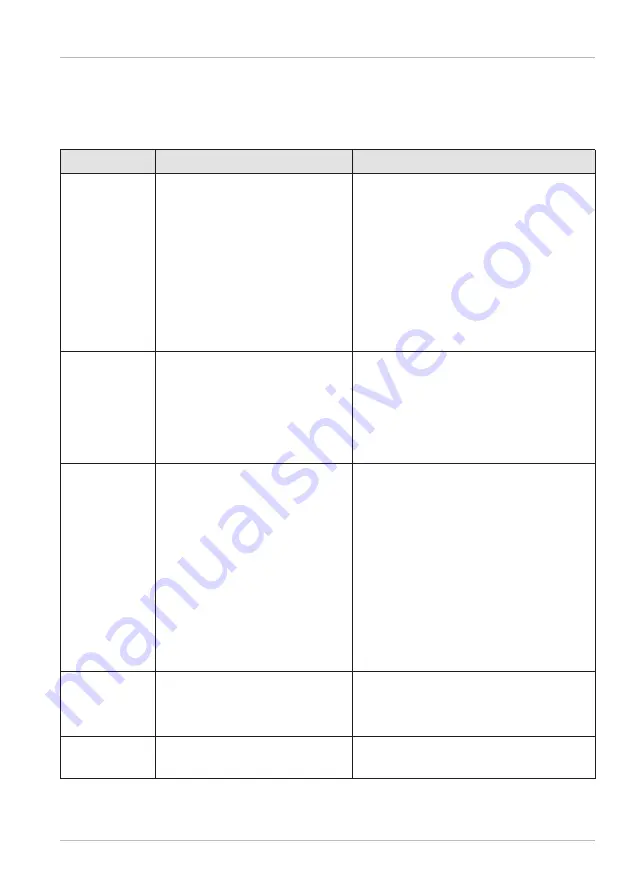

Problem

Possible cause

Solution

No material

in the nozzle.

• Nozzle plugged.

• Clean the nozzle.

• Suction tube plugged.

• Clean the suction tube.

• Adjusting screw for ma-

terial flow control turned

too far to the left (–).

• Turn the adjusting screw for

material flow control to the right

(+).

• Suction tube loose.

• Insert the suction tube.

• Pressure does not build

up in the paint container.

• Screw the paint container firmly

in place.

Material

drips out of

the nozzle.

• Nozzle loose.

• Tighten the nozzle.

• Nozzle worn out.

• Change the nozzle.

• Nozzle seal worn out.

• Change the nozzle seal.

• Build-up of material in

the air cap and nozzle.

• Clean the air cap and nozzle.

Spray not

fine enough.

• Material viscosity too

great.

• Thin the material.

• Adjusting screw for ma-

terial flow control turned

too far to the right (+).

• Turn the adjusting screw for

material flow control to the left

(–).

• Nozzle dirty.

• Clean the nozzle.

• Air filter very dirty.

• Clean or change the air filter.

• Not enough pressure

built-up in the paint

container.

• Screw the paint container firmly

in place.

Spray jet cuts

out.

• Material in the paint con-

tainer almost out.

• Top up material.

• Air filter very dirty.

• Clean or change the air filter.

Paint runs.

• Too much material

applied.

• Turn the adjusting screw for

material flow control to the left (–).