2024 series Tooling

(HK1077)

Alcoa Fastening Systems

7

S

ERVICING

THE

TOOL

GENERAL

1. The effi ciency and life of any tool depends

upon proper maintenance. Regular inspection

and correction of minor problems will keep tool

operating effi ciently and prevent downtime. The

tool should be serviced by personnel who are

thoroughly familiar with how it operates.

2. A clean, well-lighted area should be available for

servicing the tool. Special care must be taken

to prevent contamination of pneumatic and

hydraulic systems.

3. Proper hand tools, both standard and special,

must be available.

4. All parts must be handled carefully and

examined for damage or wear. Always replace

Seals, when tool is disassembled for any reason.

Components should be disassembled and

assembled in a straight line without bending,

cocking, or undue force. Disassembly and

assembly procedures outlined in this manual

should be followed.

5.

Service Parts Kit 2024KIT

includes consumable parts

and should be available at all times. Other

components,

as experiece dictates, should also be available.

DAILY

1. If a Filter-Regulator-Lubricator unit is not being

used, uncouple air disconnects and put a few

drops of Automatic Transmission Fluid or light

oil into the air inlet of the tool. If the tool is in

continuous use, put a few drops of oil in every two

to three hours.

2. Bleed the air line to clear it of accumulated dirt or

water before connecting air hose to the tool.

3. Check all hoses and couplings for damage or air

leaks, tighten or replace if necessary.

4. Check the tool for damage or air/hydraulic leaks,

tighten or replace if necessary.

5. Check the nose assembly for tightness or

damage, tighten or replace if necessary.

6. Check stroke periodically, if stroke is short add

oil.

WEEKLY

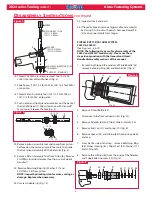

1. Disassemble, clean, and reassemble nose

assemblies per applicable nose assembly

instructions.

2. Check the tool and all connecting parts for

damage or oil/air leaks, tighten or replace if

necessary.

as experiece dictates, should also be available.

WARNING: Inspect tool for damage or

wear before each use. Do not operate if

damaged or worn, as severe personal

injury may occur.

O

PERATING

I

NSTRUCTIONS

BLIND FASTENER INSTALLATION:

The fastener may be placed either in the work hole or in

the end of the nose assembly. In either case, tool and nose

assembly must be held against work and at right angles to

it. Depress trigger and hold it depressed un l fastener is

installed and pintail breaks. Release trigger.

MAGNA GRIP® FASTENER INSTALLATION:

Place pin in work-hole and place collar over pin. See

WARNINGS

. (If collar has only one tapered end, that

end

MUST

be out toward tool.) Hold pin in hole. Push

nose assembly onto pin protruding from collar un l anvil

touches collar. Press trigger and hold down un l collar is

swaged and pintail breaks. Release trigger.

WARNINGS:

Inspect tool for damage or wear before

each use. Do not operate if damaged or

worn as severe personal injury may occur.

Pulling on a pin (fastener) without a collar,

or with collar chamfer against workpiece,

may result in pin becoming a high speed

projectile when pin grooves are stripped

or pintail breaks off. Fatal or severe injury

is possible to anyone in the pins line of

fl ight. This includes pins that ricochet.

Broken pintails eject from defl ector with

speed and force. Be sure pintail defl ector

is directed safely away front operator

or the personnel in the area. Ejecting

pintails striking anyone may cause serious

personal injury. For Models 202B and

202V, pintail bottles must always be used.

Replace damaged pintail defl ectors and

bottles as serious personal injury may

occur from pintails when using these

defective parts.

CAUTION: Remove excessive gap from

between sheets for enough of the pintail

to stick out of the collar for all of the

jaw teeth to grip into the pintail grooves.

Jaws not fully gripping pintail grooves

will be stripped or broken

.