Braddan Shower Tray

Installation And User Care Instructions

Failure to install this AKW product in accordance with supplied instructions or the making of unauthorised modifications will

invalidate any warranty and will affect product safety.

AKW, Pointon Way, Hampton Lovett, Droitwich Spa, WR9 0LR

Tel.+44 (0) 1905 823298 - Fax. +44 (0) 1905 823297 - www.akw-ltd.co.uk

© 2018 AKW

01-018-200-09

To order additional products or parts please call: 01905 823299 or on the details above

Read ALL instructions carefully BEFORE installation and leave with the end user

Sizes Avaliable

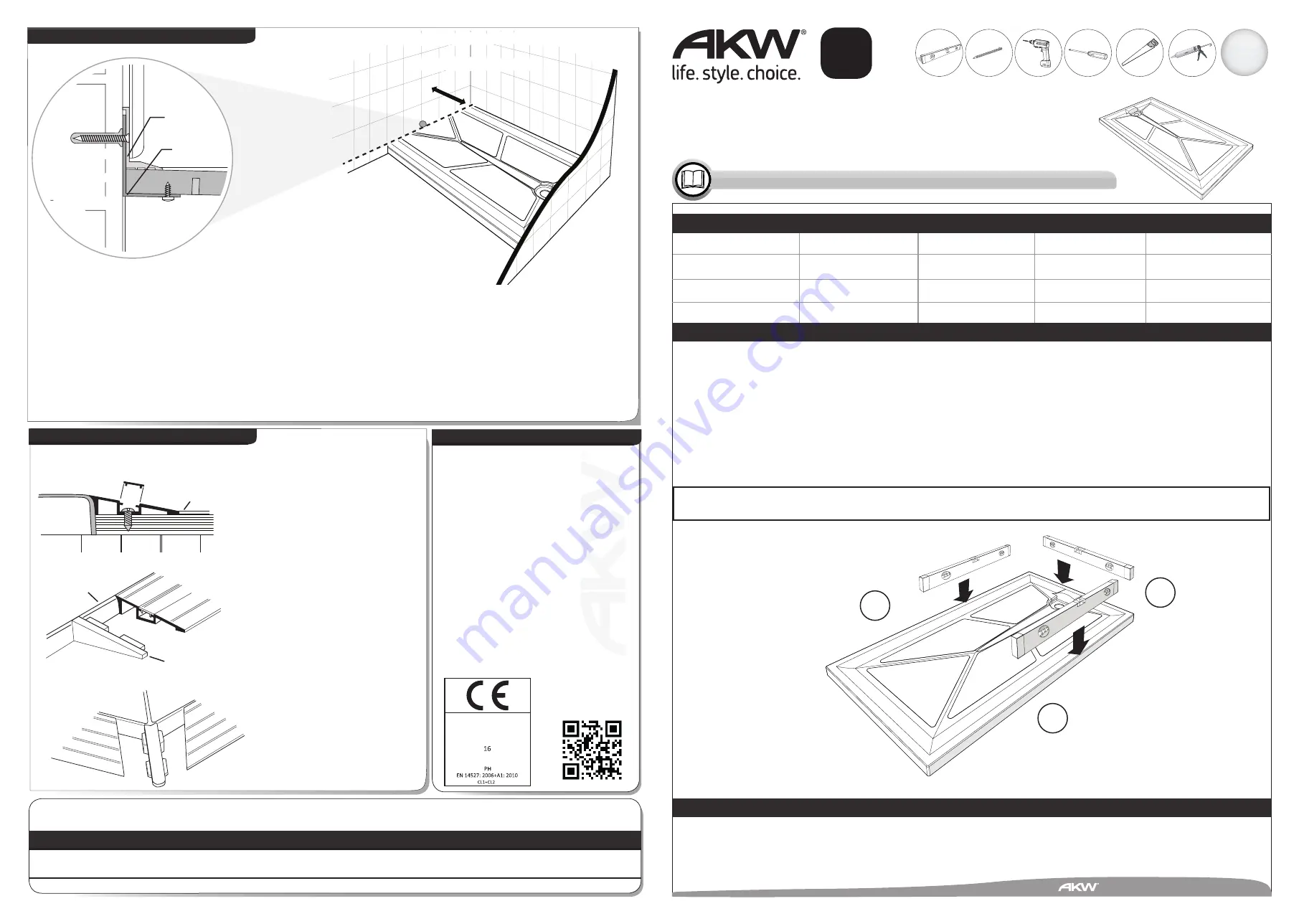

Place ramp onto a level floor and

against tray, ensure ramp is flush

with tray edge and in

appropriate position. Mark off

fixing holes, drill and insert

suitable fixings in the floor.

Apply silicone sealant to contact

area of ramp before fixing with

No.8 x 38mm (1

1

/

2

”) pan head self

tapping screws. Snap in

plastic sections to close fixing

cavity and place end caps to ramp

using adhesive. Note: For ramps

that continue around corner of

tray, a 45º joining piece is

supplied. These ramps may

require cutting to size. Ensure

that silicone is applied between

joining piece and tray and joining

piece and ramp.

(See Figs. 11, 12 and 13)

.

Guaranteed

for

Life

Fig.13

45º joining piece

Step 4 - Braddan Ramps

800x800

820x820

900x900

1000x700

1000x800

1000x1000

1200x650

1200x700

1200x760

1200x820

1200x900

1300x700

1300x820

1420x700

1420x820

1500x700

1500x820

1700x700

1800x700

1800x820

Installation

IMPORTANT

Before completing the installation, water test the flow from tray into waste for correct installation and drainage efficiency.

It is important to ensure that the floor is level in all directions before putting the tray into place. If water puddles away from

the waste, this is a clear indication that the levels are not correct - the water is acting as a ‘spirit level’.

The sides on the tray

A

and

B

may well show level on testing, but if point

C

is low, then water will puddle in the area of point

C

and the only remedy is to level the floor and refit the tray. The tray has ‘lands’ on all four sides.

Use a spirit level front to back and side to side - all ‘lands’ must be level (

ABC

) - the fall is moulded into the tray

(See Fig. A)

.

It is not necessary to remove plaster from the walls for installing the above trays. When tiling, ensure that the bottom row of

tiles are bedded in to align with the final position of the tray.

Fig. A

The Braddan Shower Tray should be cleaned periodically to remove any accumulation of hair or other waste material, using

normal domestic bathroom cleaning materials. Do not use strong or concentrated acidic, alkaline or other cleaning materials as

these may damage or discolour the product. After cleaning always flush down with water then wipe thoroughly with a damp

cloth to remove any cleaning material residues before drying off.

Available Sizes (mm)

Usercare Instructions

End Cap

Silicon Seal

Snap in

Vinyl Flooring

Flush

Fig. 11

Fig.12

UK

UK

UK

UK

5mm

4mm

3mm

A

B

C

Technical Help line

01905 560219

Technical Help line

01905 560219

Orderline

01905 823299

General Enquiries

01905 823298

Fax

01905 823297

Website

www.akw-ltd.co.uk

Quotes & orders email

Enquiries email

Contact

ALL GRP TRAYS

Label for

Product

Packaging

Manual

Note

DoP numbers are

Braddan

Tri-form

09-012-075

GRP Braddan

01-018-330

Sulby

01-018-331

Sulby 2

01-018-332

Multi Spec

01-018-333

Low Profile

01-018-334

DoP 01-018-330

07-003-050

DoP

DoP 01-018-330-02

07-003-050-02

DoP

AKW Limited

Pointon Way, Hampton Lovett

Droitwich Spa, WR9 0LR

United Kingdom

www.akw-ltd.co.uk

AKW Limited

Pointon Way, Hampton Lovett,

Droitwich Spa, WR9 0LR

United Kingdom

www.akw-ltd.co.uk

DoP 01-018-330-02

07-003-050-02

DoP

For latest AKW news and

products, scan this code

with your phone or tab

device.

300mm MAX Cut down length

See Instructions 07-003-020 for more information on Cut-to-length.

The Braddan 1800 tray has a cut to length area that can be cut to suit the dimension between walls down to 1500mm.

Use a fine toothed blade in either jigsaw or handsaw (cut from below with jigsaw or from above with handsaw).

Allow for thickness of trim angle ‘B’ (2mm or

1

/

8

”) when cutting tray to size

(See Fig. 10)

.

After trimming tray and angles A & B to size, mastic underside of tray in position of angle ‘B’ placement. Fit angle ‘B’ to

underside of tray with stainless steel screws. Place tray onto a prepared level floor and between walls, ensuring that angle

‘B’ is tight against end wall. Place angle ‘A’ onto tray and against angle ‘B’ then drill 4.5mm (

3

/

16

”) diameter holes on ‘v’ groove

location through both angles (drill countersunk holes in angle ‘A’). Remove angle ‘A’ then drill through previously drilled holes in

angle ‘B’ with a No.10 / 5mm masonry drill into wall and fit plastic wall plugs. Silicone seal undersides of angle

‘A’ then fix to wall with No. 8x38mm (1

1

/

2

”) countersunk head stainless steel screws. Silicone seal between angle ‘A’ and tray if

required. If required the trimmed tray edge is now ready for end moulding.

(See cut-to-length instructions 07-003-020)

.

Step 3 - Cutting 1800mm Tray to length

Fig. 10

No.8 x 13mm

(

1

/

2

”

) Pan Head

Screws

Angle A

Angle B

4.5mm (

3

/

16

”

)

dia. holes

No.8 x 38mm

(

1

1

/

2

”

)

Countersunk

Screws