Manual E

0905e

EDITION 2010

Pneumatic Actuators

MANUAL

Modifications reserved. Date 06.2011.

No guarantee for accuracy.

Older data sheets are invalid.

C.

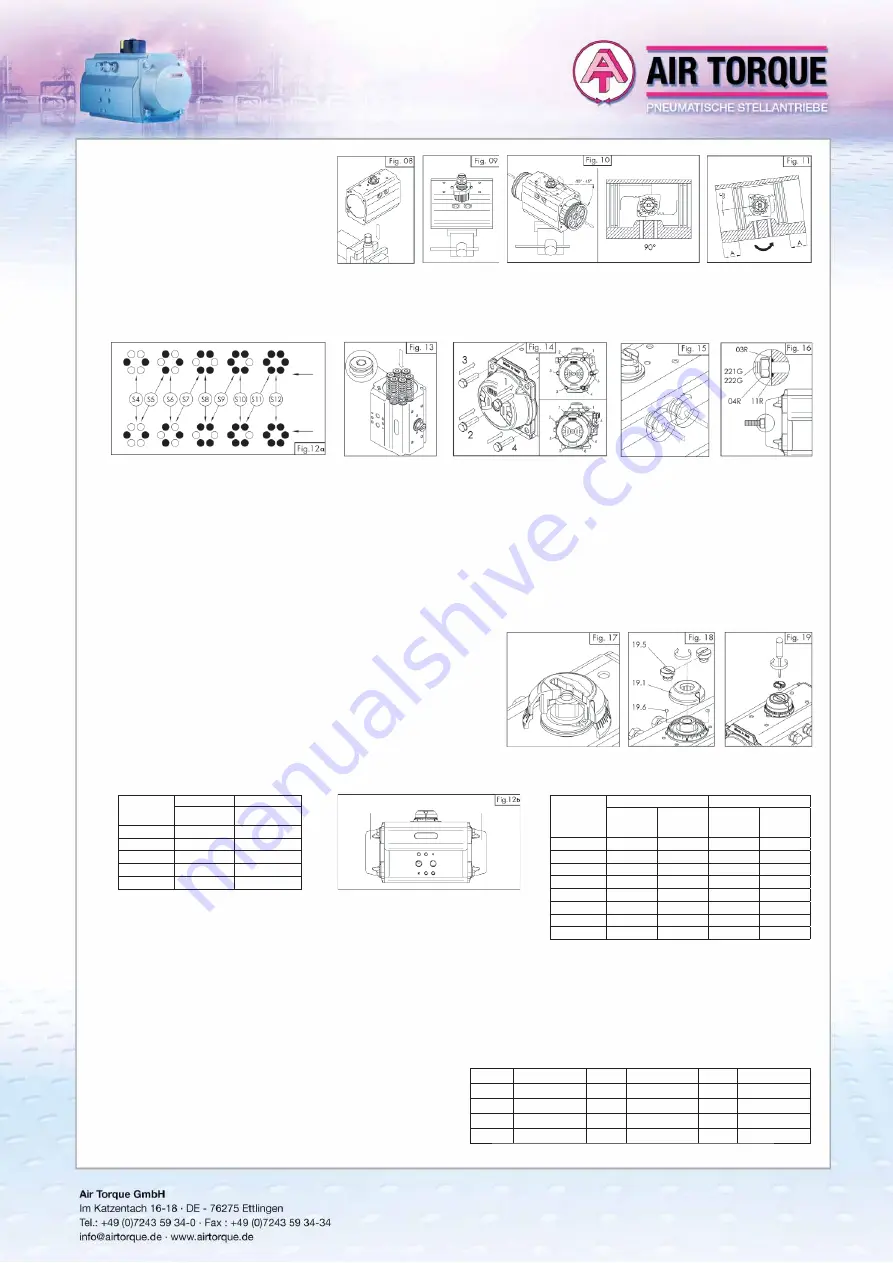

End cap (Part N° 30) assembly,

fi gures 12, 13 and 14:

•

Assemble one end cap at a time.

•

Lubricate the body.

•

For spring return actuators, insert the springs in

each end cap according to the desired con-

fi guration, as shown in fi gure 12 and related

tables. For models DRSC00030U -> DRSC5000U

insert spring cartridges as shown in fi gure 13.

•

Fit end cap o-ring seal (14) into the groove on both end caps.

•

Fit end caps onto the body (50), verifying that the o-ring remains in the groove.

•

Only for actuators with 50% or 100% stroke adjustment, ensure that the adjustment screws 221G/222G are completely screwed into the end-cap.

•

Insert the cap screws (13) and tighten each only partially. Complete tightening by making 1-2 turns for each screw in the sequence shown in fi gure 14

until tightening is completed. See the table for screw tightening torque.

D.

Assembly of stop cap screws (Part 02) and stroke adjustment for models DRSC00015U -> DRSC5000U, fi gures 15 and 16:

•

Fit the stop cap screws (02) in the body.

•

Stroke adjustment for actuators with standard type “ST” rotation / assembly (clockwise to close).

Stroke adjustment in close position: with the actuator in close position 0°, screw or unscrew the right (from top view) stop cap screw until the desired

stop position is achieved. Then tighten the stop adjustment nut (04) to lock it in place.

Stroke adjustment in open position: with the actuator in open position 90°, screw or unscrew the left (from top view) stop cap screw until the desired

stop position is achieved. Then tighten the stop adjustment nut (04) to lock it in place.

For spring return actuators, it could be necessary to make rotation tests to verify the correct stroke adjustment in open position.

•

Only for actuators with adjustment 50% or 100%, fi t on end-cap adjustment screws 221G/222G the o-rings 11R, the washers 03R and the nuts 04R.

To adjust the stroke in open position: with the actuator in partially or totally open position, screw or unscrew the end-cap adjustment screw 221G/222G

until the desired position is achieved.

It is important that the two end-cap adjustment screws are both in contact with the pistons. Then lock the nuts 04R.

E.

Assembly of graduated ring and position indicator (Part N° 19,19.0,19.1), fi gures

17,18 and 19:

•

Fix the graduated ring (19.0) to the body.

•

If necessary, correctly position the “Top Adaptor” (19.5) and lock it with the proper

screws (19.6).

•

Insert the indicator (19 or 19.1) making sure that it indicates the correct actuator

position.

•

Screw the indicator screw (39) if assembled.

Spring Set

Side B

Side A

DRSC00010U

Spring type

DRSC00010U

Spring type

S1-1

1 (green)

1 (green)

S1-2

1 (green)

2 (red)

S2-2

2 (red)

2 (red)

S2-3

2 (red)

3 (black)

S3-3

3 (black)

3 (black)

Spring Set

Side B

Side A

DRSC00015U

Internal

spring type

DRSC00015U

External

spring type

DRSC00015U

Internal

spring type

DRSC00015U

External

spring type

S1

1 (green)

-------

-------

2 (black)

S2

-------

2 (black)

-------

2 (black)

S3

-------

2 (black)

-------

3 (red)

S4

-------

3 (red)

-------

3 (red)

S5

-------

3 (red)

1 (green)

2 (black)

S6

1 (green)

2 (black)

1 (green)

2 (black)

S7

1 (green)

2 (black)

1 (green)

3 (red)

S8

1 (green)

3 (red)

1 (green)

3 (red)

Tab.01: Spring set confi guration DRSC00010U

Tab.02: Spring set confi guration DRSC00015U

Spring set confi guration of SC/SO00010U and SC/SC00015U:

Side A

Side B

Side A

Side B

7. STORAGE

INSTRUCTIONS

If the actuator is not for immediate use, the following precaution must be taken for storage:

•

Store the actuator in a clean and dry environment and at temperature between –20°C (-4°F) and +40°C (+104°F).

•

It is recommended that the actuator be stored in its original box.

•

Do not remove the plastic plugs on air supply ports.

8.

LIFTING and HANDLING

It is recommended to lift the actuators with proper, adequate and permitted systems in relation to the actuator weight and by following the ruling laws

in terms of safety and health protection. The weight of the actuators is indicated on the Air Torque catalogue and on the related technical data-sheets.

During the lifting and the handling of the actuators, it is recommended to avoid clashes and/or accidental falls in order to avoid irreparable damages

to the actuators and to compromise the functionality.

Contact Air Torque for any information and technical data-sheets.

9.

NOTES regarding the FLANGE CONNECTION

Extract from the standard DIN ISO 5211:

The torque values in the following table show the maximum torques which

are allowed to be transmitted by the flange connection:

Flange

Md max.all. (Nm)

Flange

Md max.all. (Nm) Flange Md max.all. (Nm)

F03

32

F10

500

F25

8 000

F04

63

F12

1 000

F30

16 000

F05

125

F14

2 000

F07

250

F16

4 000