9

MN-282

RideControl

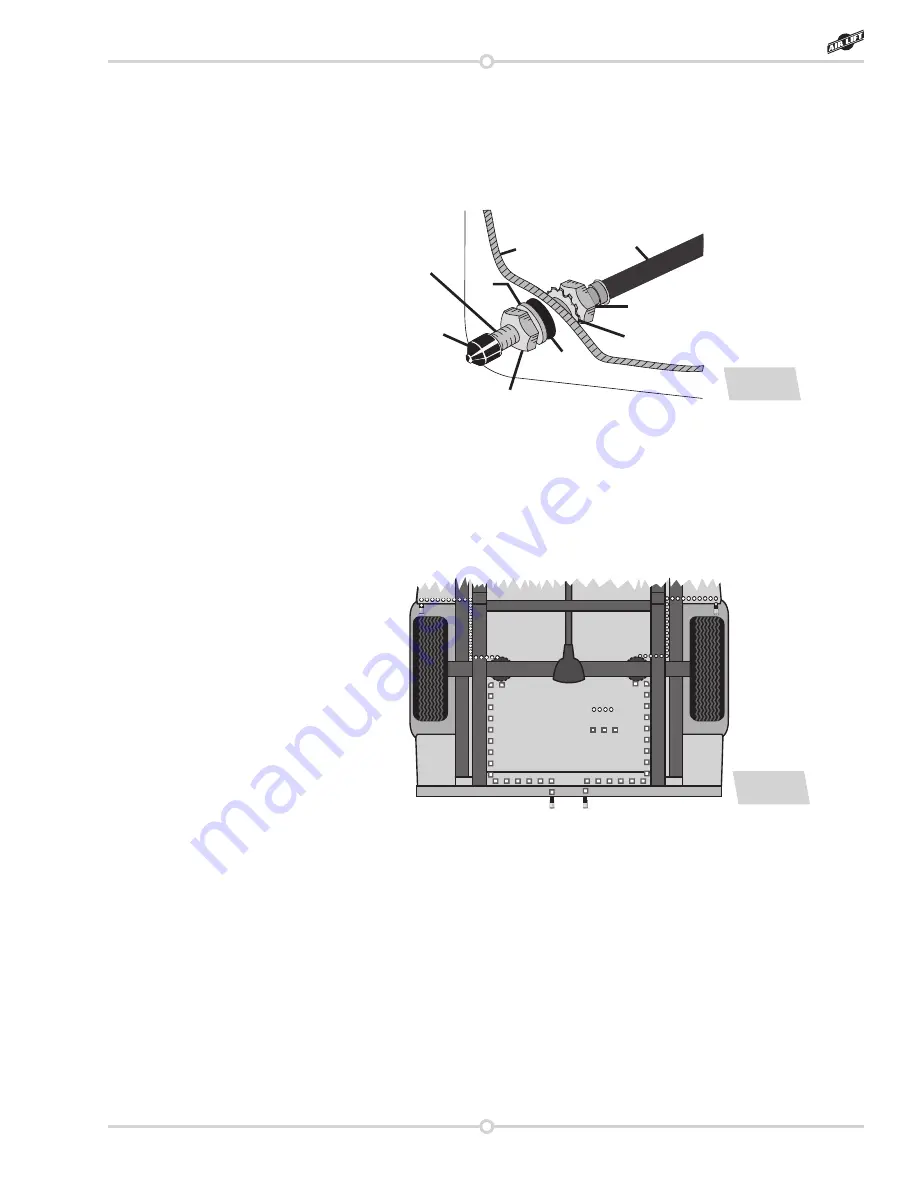

2 . Drill two 5/16” holes to install the inflation valves .

3 . Cut the air line assembly in two equal lengths .

4 . Place a 5/16” nut and star washer on the air valve . Leave enough of the inflation valve

in front of the nut to extend through the hole and have room for the rubber washer, flat

washer, and 5/16” nut and cap . There should be enough valve exposed after installation

– approximately 1/2” – to easily apply a pressure gauge or an air chuck . (Fig . 8)

Air line to

air spring

Star

washer

Vehicle body

or bumper

Hex nut

Hex nut

Rubber

washer

Flat

washer

Valve

Cap

Schrader

valve

fig. 8

5 . Push the inflation valve through the hole and use the rubber washer, flat washer and

another 5/16” nut to secure it in place . Tighten the nuts to secure the assembly .

6 . Route the air line along the frame to the air fitting on the air spring (Fig . 9) . Keep

AT LEAST 6” of clearance between the air line and heat sources, such as the exhaust

pipes, muffler, or catalytic converter . Avoid sharp bends and edges . Use plastic tie straps

to secure the air line to fixed points along the chassis . Be sure that the tie straps are tight,

but do not pinch the air line . Leave at least 2” of slack to allow for any movement that

might pull on the air line .

7 . Cut off the air line, leaving approximately 12” of extra air line . A clean square cut will

prevent leaks . Insert the air line into the air fitting . This is a push-to-connect fitting .

Simply push the air line into the 90° swivel fitting until it bottoms out (9/16” of air line

should be in the fitting) .

fig. 9

Option 1:

Option 2:

ALIGNING THE AIR SPRING

1 .

VERY IMPORTANT

– The upper and lower brackets are slotted in order to assist in

aligning the air spring correctly between the brackets . With the top and bottom still

loose, inflate the air springs to approximately 10 PSI . Tap the air spring inboard or

outboard to achieve proper alignment . There should be a symmetrical cushion of air

around the base of the air spring when correctly positioned . Once the air springs are

aligned correctly, torque the upper mounting bolt to a maximum of 4 lb .-ft . (5Nm) and

the lower mounting bolt to a maximum of 20 lb .-ft . (27Nm)

2 . Install the wheels and torque to manufacturers specifications, remove the safety

stands and lower the vehicle .

Summary of Contents for RideControl 59516

Page 2: ......

Page 17: ...15 MN 282 RideControl Notes...