The shaft driving the incoming roller is turning at 1000 rpm, and the shaft driving the outgoing roller

is turning at 1250 rpm.

You want the tachometer to:

1. Compute Speed A (Incoming roller) and Speed B (out-going roller) in FPM.

SF fpm = 60 x

π

x D’ = 60 x 3.1416 x 3’ = 565.4880

PPR 48 48

C

1

= 565.5

C

2

= 48.00

C

3

= 565.5

C

4

= 48.00

2. Send the percentage of elongation to Display, ratio to Setpoints I and 2, and Speed B only to

Analog Output.

C

11

= x 5 5 2 9

3. Have Display show FPM with autoranging fixed to one decimal place.

C

5

=1000

C

12

= 1

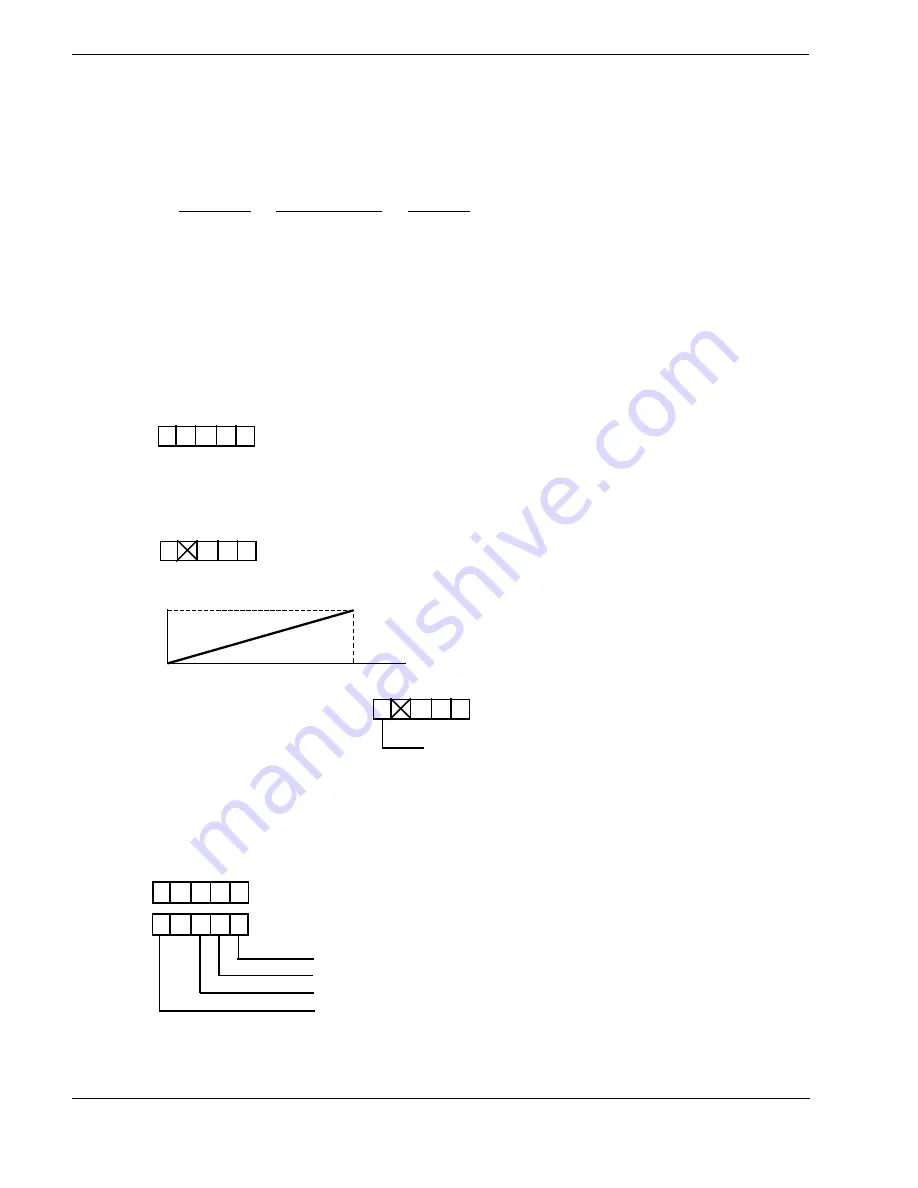

4. Have the Analog Output drive an auxiliary 4 - 20mA recorded which has a range of 0 to 5000fpm.

20mA

4mA

0 fpm 5000

C

6

= 0000

C

12

= 1

C

7

= 5000

blank

5. Use the setpoints for web break detection, with Setpoint 1 going to alarm if the ratio is less than

0.5, and Setpoint 2 going to alarm if the ratio is less than 1.0. Relays are latching.

C

8

= 0.500

C

9

= 1.000

C

10

= x 0 0 0 0 (no hysteresis)

C

12

= x 5 5 1

autoranging fixed to one decimal place

latching relay

latching relay

analog output is 4 - 20mA

12

Summary of Contents for TACHTROL 3

Page 1: ...TACHTROL 3 ...

Page 23: ...2 NEMA 4X 3 X STYLE 4 LESS ENCLOSURE STYLE 19 ...