38

USER MANUAL

The pump has been tested before getting out from the line of production and

therefore it is ready to work. Before starting to work, it is anyhow advisable to

check the oil level and all the fi ttings, as well as if the bolts which hold it to the

sprayer are all tight.

The oil lever need to be verifi ed daily, or more frequently if the sprayer would

be working in heavy conditions.

The oil reservoir has never to be completely full. The oil level has to be about at

the middle of the glass.

The oil to be used is of the type anti-foam SAE 2O W 4O.

The oil of the pump needs to be replaced at the end of every season or at least

every 500 hours of work.

Some pumps are provided with an accumulator to control the pressure, in or-

der to avoid vibrations and pulsation.

The pressure of the accumulator has to be checked periodically with a gauge.

The correct pressure setting of the accumulator is shown on the manual of the

pump and, as reference it has to be the 10% of the pressure used for working.

For any more information about the pump, read and understand the manual of

the pump.

1. Valve and O-ring Replacement.

- Occasionally debris can cause the valves to not seat properly or damage the

oring.

To check for this problem, follow these steps : remove the pump manifold (

see parts list for your model ), with manifold removed, valves can readily be

removed and checked for debris or wear.

-To replace valves or O-rings, refer to parts list for appropriate kits.

LUBRICATION

Summary of Contents for DELTA

Page 1: ...1 USER MANUAL MOUNTED FIELD SPRAYER USER MANUAL www agrional com DELTA 400 600 LITER ...

Page 2: ...INSURES THE FUTURE ...

Page 3: ...USER MANUAL SPARE PART LISTS ...

Page 33: ...33 USER MANUAL CALIBRATION AND RATE ...

Page 46: ...SPARE PARTS ...

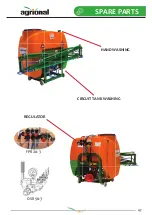

Page 47: ...47 SPARE PARTS REGULATOR CIRCUIT TANK WASHING HAND WASHING FPR 20 3 OSR 50 3 ...