5 Maintenance and Repair

34

Sweeper

agria 7100 comfort

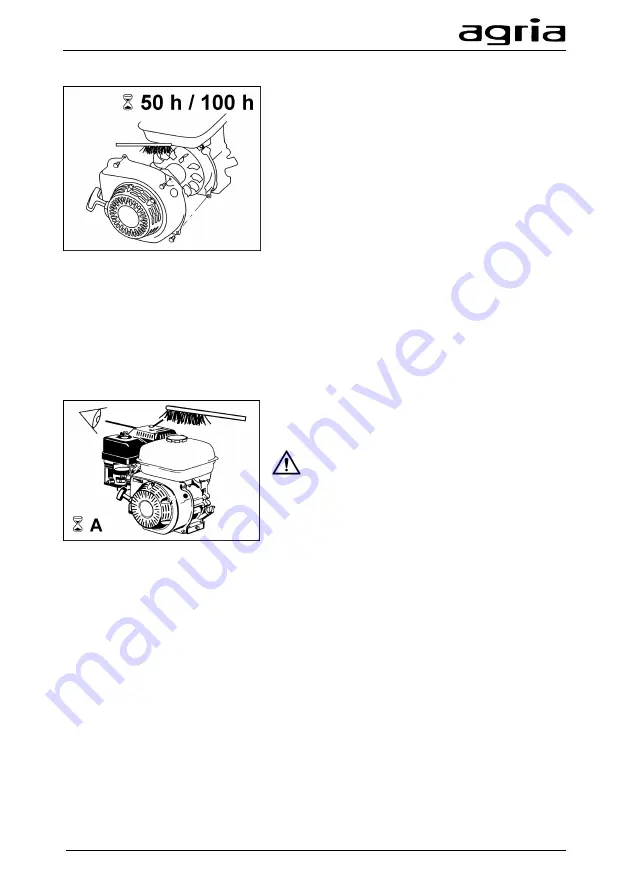

Air cooling system

1.) Clean rotating fan wheel at least every

50

hours of operation (sooner in case of heavy dust

and plant debris accumulation); remove the fan

housing to do this.

2.) Clean the interior cooling fins and surfaces at

least every

100

hours of operation (sooner in

case of heavy dust and plant debris accumula-

tion).

- agria-Service -

Regulator

For proper engine function, keep regulator link-

age, springs and controls on the carburettor

(B/2) clean and free of dirt. Ensure that no parts

are bent or out of adjustment.

Exhaust

Clean the surrounding area of the exhaust pipe

(B/9) at regular intervals from grass, dirt and

combustible debris. There is a

fire hazard!

Check before each start-up.

Replace damaged exhaust parts.

Speed control

The speed governor must be correctly adjusted

in order to start, operate and stop the engine at

the correct speed.

- agria-Service -