11

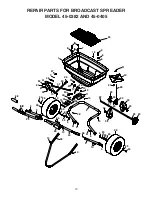

REPAIR PARTS FOR BROADCAST SPREADER

MODEL 45-0382 AND 45-0405

the

fastest way to purchase parts www.speedepart.com

Ref. Part Qty.

Description

No. No.

1

44466

1

Hopper, Spreader (15 lb.)

4884

1

Tube, Frame (45-038)

4884SS

1

Tube, Frame (45-0405)

3

5755

Handle, Lower (45-038)

5755SS

Handle, Lower (45-0405)

4 741-049 4

Bearing, Flanged

5

49910

Spacer, Axle Tube ss

6

1543-69 7

Washer, Nylon

7

49890

7

Washer, 1/4 in. Std. ss

8

567

Clip

9

4989

6

Bolt, Hex 1/4-0 x 1-3/4 ss

10

49891 19

Nut, Hex 1/4-0 Nylock ss

11

65457

1

Weldment, Guide Closure

1

49894

4

Bolt, Slot Truss 10-3 x 1/ in. ss

13

4485

1

Bushing, Hopper

14

49895

4

Hex Nut, 10-3 Nylock ss

15

5757

1

Pattern, Plate

16

3533

1

Closure, Plate

17

5917

1

Slide Gate Angle Bracket ss

18

4388

Rivet, POP ss 3/16 in.

19

5758

1

Link, Flow Control ss

0

40199

Bolt, Hex 1/4-0 x 3/4 in. ss

1

49798

Fitting. Grease 1/4 in.

5759

1

Shaft, Axle Spreader ss

3

4709

1

Gear, Large

4

4704

1

Yoke, Large

5

49899

7

Washer, Flat 5/8 in. ID x 1 in. OD

6

43659

1

Spring, Pin, 3/16 x 1 in.

7

46055

3

Spring, Pin 1/8 x 1 in.

8

49896

1

Shaft, Impeller ss

Ref.

Part

Qty. Description

No.

No.

9

4705

1

Gear, Small

30

4367

1

Impeller

31

48934

1

Agitator, Hairpin

3

471

Housing, Large Gear

33

49897

Hairpin, Clip Large

34

49898

1

Hairpin, Clip Small

35

49930

Spacer, Tube

36

49907

Wheel, Poly 5/8 in. ID x 13-5.00

37

4990

1

Flow Control Rod

38

576

1

Tube Stand (45-038)

576SS

1

Tube Stand (45-0405)

39

49909

8

Bolt, Hex 1/4-0 x 1-1/ in.

40

5761

Handle, Upper (45-038)

5761SS

Handle, Upper (45-0405)

41

4855

1

Flow Control Bracket

4

49908

3

Bolt, Hex 1/4-0 x -1/ in. ss

43

5760

1

Lever, Flow Control

44

43848

1

Grip, Control Arm

45

5763

1

Stop, Adjustable ss

46

49903

1

Bolt, Carr. 1/4-0 x 3/4 in.

47

47141

1

Nut, Wing 1/4-0 Nylon

48

49904

Grip, Handle

49

49931

1

Screw, Thumb 1/4-0 x 1-1/4 in.

50

49901

1

Spring, ss

5

14

1

Pin, Cotter 1/8 x 3/4 in.

53

4049

1

Pin, Cotter 5/3 x in.

54

49911

Pin, Cotter 9/64 x 1-1/ in.

55

47441

1

Screen, Spreader

56

4050

1

Nut, Nylon

49905

1

Owners Manual (Not Shown)