8

ATTENTION:

When broadcasting weed control

fertilizers, make sure broadcast

pattern does not hit evergreen trees,

flowers or shrubs.

Light

Heavy

Fertilizer

Granular

3

5

Pelleted

5

7

Grass Seed

Fine - Blue Grass

2

4

Coarse - Rye, Fescue

6

8

Ice Melters

Granular

6

8

Pelleted

6

8

MATERIAL

TYPE

Flow Rate Setting

At 3 M.P.H.

FLOW RATE CHART

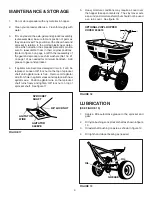

1.

Determine approximate square footage of area to be

covered and estimate amount of fertilizer or seed

required.

2.

With flow control arm in

off position

, set flow rate

gauge at number indicated in flow rate chart for light or

heavy application rate.

Also, refer to instructions on

bag for manufacturers recommended settings.

3.

Break up lumpy fertilizer as you fill hopper.

4.

To broadcast, always have spreader in motion before

opening closure plate.

Do not allow spreader to sit

stationary with flow control arm in ON position.

If

fertilizer is accidentally deposited to heavily in small

area, soak down thoroughly with garden hose to pre-

vent burning of lawn.

IMPORTANT: Application rates (shown on chart)

are affected by humidity and mixture content of

material (granular and pellet); therefore, minor

adjustment settings may be necessary to compen-

sate for this condition. The rate chart is calculated

for light and heavy application. The faster you

walk, the wider the broadcast width. A variation in

speed will determine the flow rates and width of

broadcast.

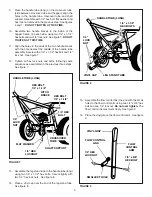

FIGURE 16

OPERATION

The application spread pattern should overlap to insure

uniform coverage at the edges. The approximate distance

between each pass is shown in the application diagram.

See figure 15.

FIGURE 15

FLOW RATE ADJUSTMENT

1.

Push forward on the flow control arm to the

off posi-

tion

and pull back to the on position. The higher the

number on flow rate gauge the larger the opening in the

bottom of the hopper. See figure 16.

2.

REFER TO THE FLOW RATE CHART AND TO

INSTRUCTIONS ON FERTILIZER BAG TO SELECT

PROPER FLOW RATE SETTING.

3.

Loosen the hand knob to set the flow gauge to the

desired flow setting and tighten the hand knob.

4.

Always move flow control arm to

off

position before

stopping or turning spreader.

5.

The spreader should be moving before you move the

flow control arm to the

on position.

OVERLAP

8' to

10'

APPLICATION DIAGRAM

1 2

3 4

5 6

7 8

9 10

OFF

ON

FLOW CONTROL ARM

FLOW RATE GAUGE

HAND KNOB

3 M.P.H. is equivalent to traveling 100 feet in 23 seconds.

Do not use powdered lime, only

granulated materials are approved

for use.

NOTE