Page 18

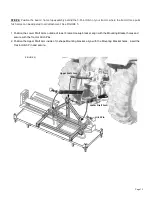

1. Move the control handle to the REVERSE position until the wedge is fully retracted to allow split wood portion to contact

the log dislodger.

2. Never remove partially split wood from the wedge with your hands. Fingers may become trapped between the split wood.

3. Once removed from the wedge with the log dislodger, split the wood from the opposite end or in another location.

Always:

1 Follow the Checklist below each time you use your log splitter for optimum performance.

[ ] Check the general condition of the log splitters, e.g.: bolts, nuts, welds, clamps, hoses, etc.

[ ] Check hydraulic level in your tractor and fill as needed.

[ ] Check hydraulic hoses for cracks or wear.

[ ] Check the frame for stability.

[ ] Check the wedge for tightness, nicks and wear.

2. Bleed the air out of the hoses before operating.

3. Be alert and turn the Tractor off if children or pets enter the work area.

4.

Use “pipe dope” on all hydraulic fittings.

5. Split wood along the grain (lengthwise) only.

Never:

1. Use when fluid is below 20° F or above 150° F.

2. Operate through relief valve for more than 5 seconds.

4. Attempt to adjust the unloading or relief valve settings.

5. Operate with air in hydraulic system.

6. Attempt to cut wood across the grain.

7. Attempt to remove partially split wood from the wedge with your hands. Fully retract the wedge to dislodge wood with

log dislodger.

8. Never allow children to operate the log splitter.

Important:

1. Move the control handle to Forward position to extend the cylinder to split. If the log has not completely split after the

cylinder extending to the end of its stroke, move the control handle to the reverse position to retract the cylinder.

2. Leaving the valve in the “accurate” position at the end of the cylinder stroke may damage the pump. To extend the life

of hydraulic system, please conform with industry safety standards, the wedge stops 2 inches from the end of the stroke.

OPERATION INSTRUCTIONS

OPERATION TIPS

REMOVE PARTIALLY SPLIT WOOD

Page 21

Summary of Contents for BE-LS22TL3PT

Page 2: ......

Page 6: ......

Page 29: ...Page 22 EXPLODED DIAGRAM PARTS LIST Page 25...

Page 32: ...Page 25 Page 28...

Page 34: ...Page 27...

Page 35: ...Page 28...

Page 36: ...Page 29 Phone 1 877 588 3311 Fax 1 800 665 7334 WWW BRABEREQ COM...