9

IMPORTANT CONSUMER INFORMATION SHEET

Check and maintain the depth of the loose-fill surfacing material. To maintain the right amount of loose-fill

materials, mark the correct level on play equipment support posts. That way you can easily see when to replenish

and/or redistribute the surfacing.

Do not

install loose fill surfacing over hard surfaces such as concrete or asphalt.

Poured-In-Place Surfaces or Pre-Manufactured Rubber Tiles

You may be interested in using surfacing other than loose-fill materials-like rubber tiles or poured-in-place surfaces.

Installations of these surfaces generally require a professional and are not “do-it-yourself” projects.

Review surface specifications before purchasing this type of surfacing. Ask the installer / manufacturer for a

report showing that the product has been tested to the following safety standard: ASTM F1292

Standard

Specification for Impact Attenuation of Surfacing Materials within the Use Zone of Playground Equipment

. This

report should show the specific height for which the surface is intended to protect against serious head injury.

This height should be equal to or greater than the

fall height-

vertical distance between a designated play surface

(

elevated surface for standing, sitting, or climbing

) and the protective surfacing below-of your play equipment.

Check the protective surfacing frequently for wear.

PLACEMENT

Proper placement and maintenance of protective surfacing is essential. Be sure to:

Extend surfacing at least 6 feet from the equipment in all directions.

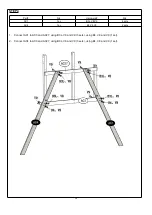

For to-fro swings, extend protective surfacing in front of and behind the swing to a distance equal to twice the

height of the top bar from which the swing is suspended.