Aerospace Filtration Systems, Inc.

MD500-IBF-KIT-OMM/IPL

Proprietary

Information

Use or disclosure of this material is subject

MD500 IBF Operation & Maintenance Manual/

to the restrictions on the title page

Illustrated Parts List - Revision B

2

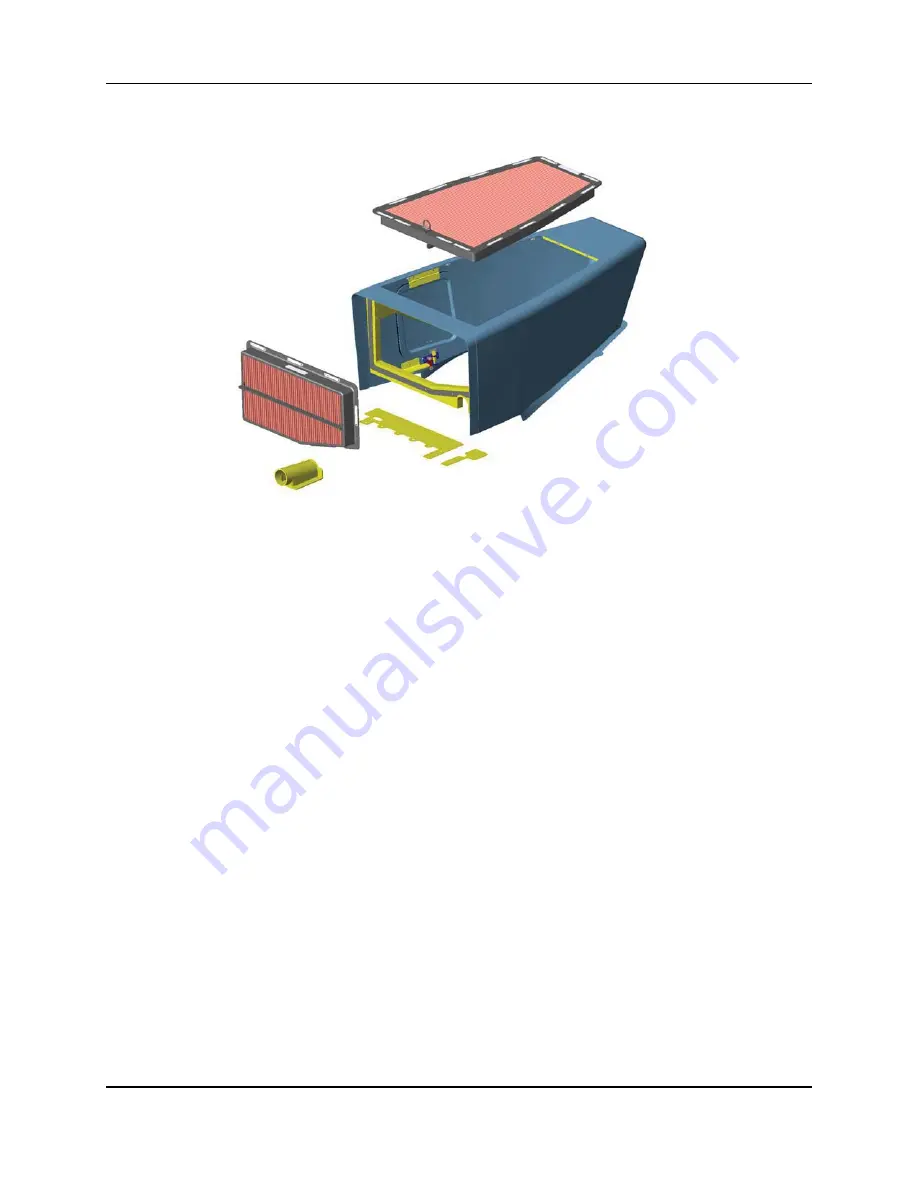

Figure 1: AFS MD500 Inlet Barrier Filter System

1.2 P

RE

-F

LIGHT

I

NSPECTION

Pre-flight inspection shall be made by the pilot to inspect the filters (forward and upper) for

damage, excessive accumulation of debris (straw, leaves, insects, etc.) or snow/ice, missing or

damaged fasteners, or the need for servicing or repair of the filters. After extended operation in

precipitation (i.e., rain, or a combination of rain and sleet/snow), the sand and dust collected on

the external side of the filter media (dirty side) may coagulate in the corners of the filter media

pleats. If visual inspection indicates existence of any of the above conditions, the decision

whether to service the filter assemblies will reside with the flight crew. Damaged or missing

fasteners should be replaced to maintain maximum seal integrity. The filter assemblies use

captive fasteners and should not need replacement during normal service. If the fastener should

become damaged, perform fastener replacement per manufacturer’s recommendations (see

paragraph 4.3). Operation with either missing fasteners and/or filter damage can severely

degrade IBF system separation efficiency and result in possible performance loss, wear, and/or

damage to the engine. Damaged filter elements should be either repaired as described in

paragraph 4.0 below or replaced.

Summary of Contents for MD500 Series

Page 2: ......