MAINTENANCE

WARNING!

Potential hazard that will result in serious injury or loss of life.

Disconnect the tool from the air supply before changing accessories, servicing, or performing maintenance.

Only use the tool after replacing or repairing the damaged parts or accessories.

Use only recommended and properly rated replacement parts and accessories. Failure to comply will lead to serious

injury or loss of life.

Repairs must be performed by a qualified service technician.

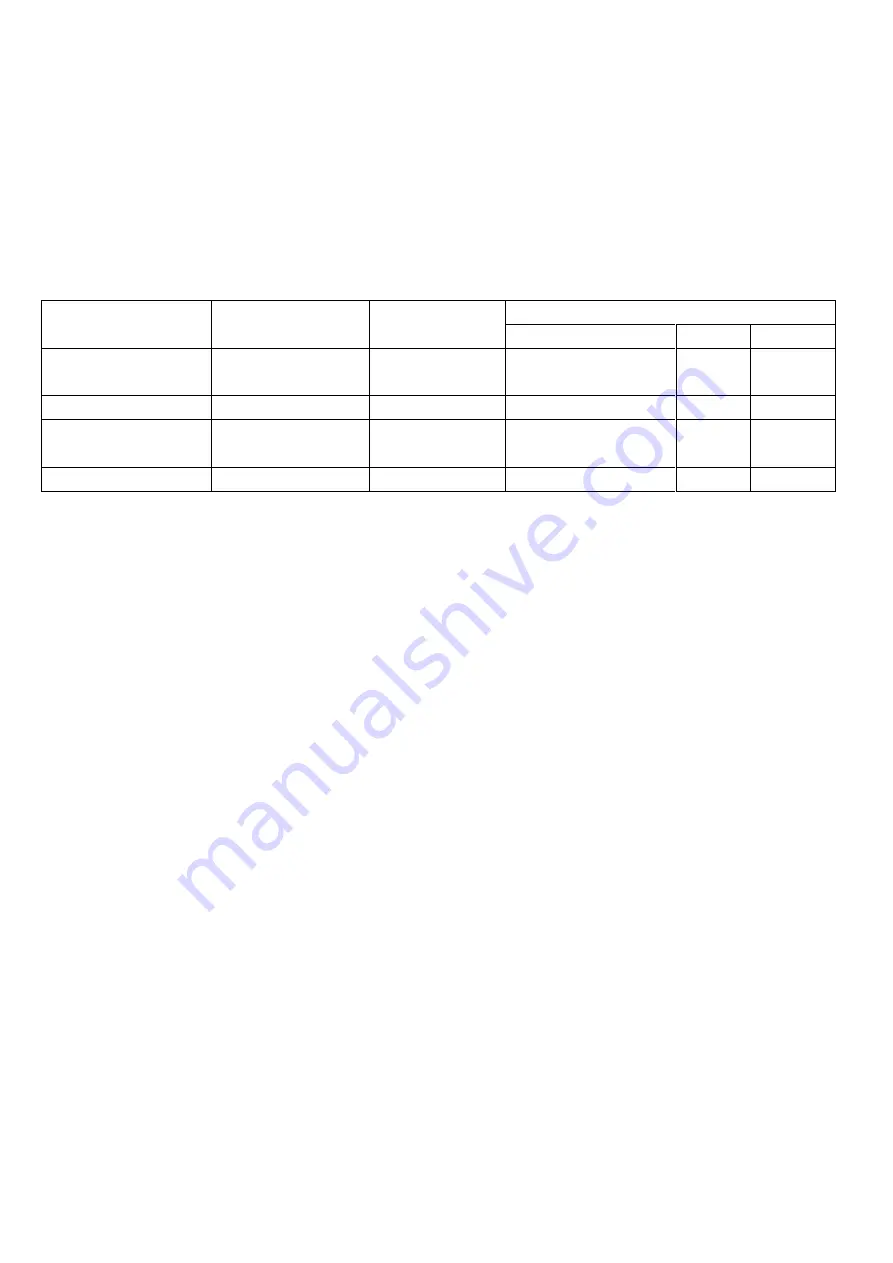

Maintenance required

Description

Tools or materials

required

Maximum service interval

Each use or every 2 hrs

Monthly

As needed

General inspection-free

movement

Trigger, spring, safety

mechanism

None

In-depth inspection

Worn or broken parts

Replace worn or broken

parts

Lubrication

See below

Pneumatic tool oil

Lubrication: If the

Air-powered impact wrench

and the compressor are not equipped with an in –line lubrication system,

place up to 6 drops of pneumatic tool oil into the air inlet before each work day or after every 2 hours of continuous

use, depending on the characteristics of work piece.

Air-operated tools must be inspected periodically, and worn or broken parts must be replaced in order to keep tools

operating safety and efficiently.

Inspect and replace worn or damaged O-rings, seals, etc. Tighten all screws and caps frequently in order to help

prevent personal injury.

Loss of power or erratic action may be due to the following

-

Excessive drain in the air line.

-

Moisture or restriction in the air pipe.

-

Incorrect size or type of hose connector. Check the air supply and follow instructions.

-

Grit or gum deposits in the tool may also reduce performance.

Inspect the trigger, the spring, and the safety mechanism for free movement on a regular basis in order to ensure that

the safety system is fully functional.

Verify that no part is loose or missing and that no part is stuck or jammed.

Disconnect the tool from the air supply, clean, and store it in a sale, dry, and childproof location, when tool is not in

use.

When temperatures are below freezing, keep tools as warm as possible using any safe, convenient method.

Check the air supply for correct size and type of hose connectors. To avoid loss of power or erratic action, ensure that

there is no additional drain on the air line and no moisture or restriction in the air pipe.

Storage:

Apply an ample amount of lubrication before storing the tool.

Run the tool for approximately 30 seconds after lubricating, in order to ensure that the lubrication is uniformly

distributed throughout the tool.

Store the tool in a clean and dry environment.