15

No.

Fault phenomena

Reasons

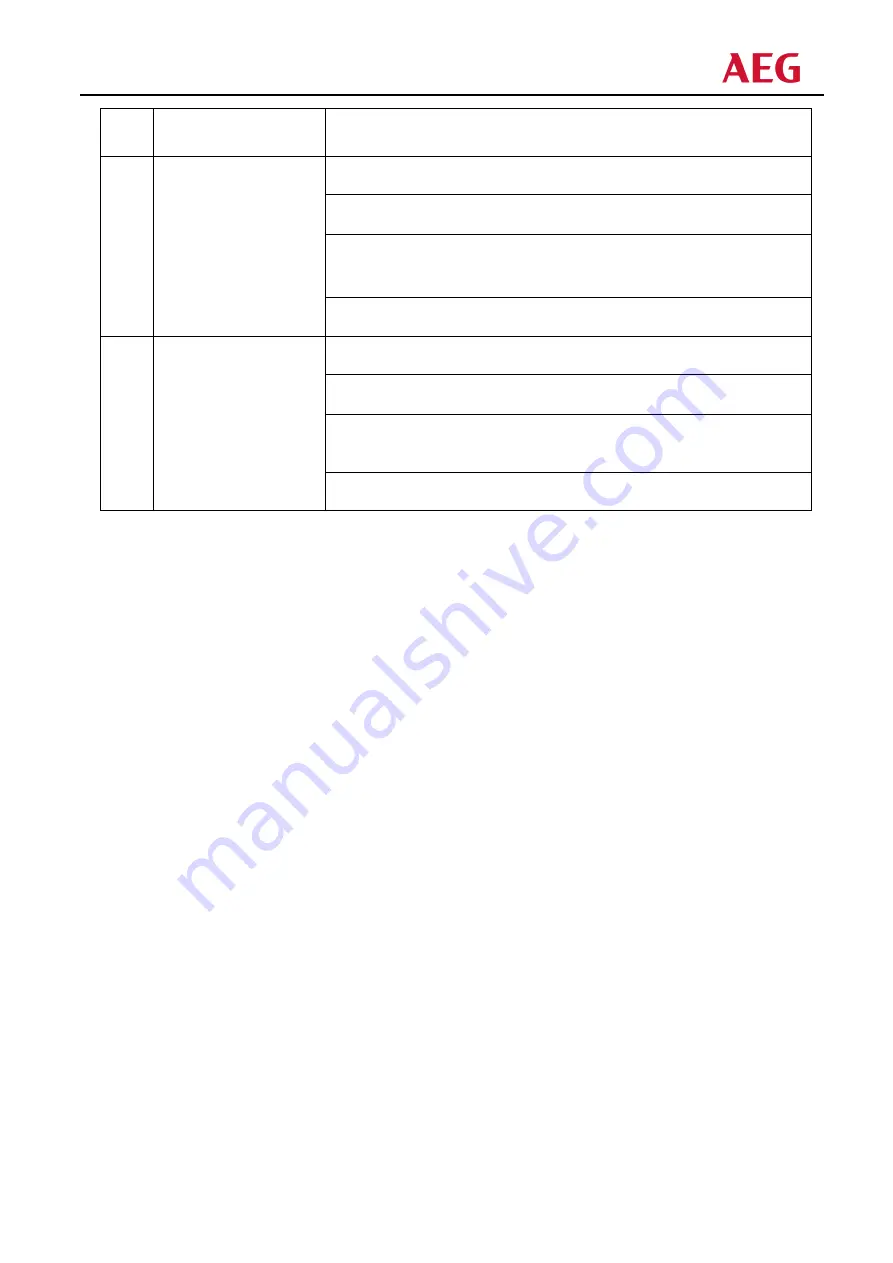

1

Failure to closing

1. The breaker is in the closing position state

2. The handcart does not fully come into operation position or test position

3. The closing locking device is employed and the auxiliary supply is

unconnected or lower than the specifications

4. secondary circuit is incorrect

2

The handcart cannot be

pushed in or pulled out

1 The breaker is in the closing position state

2 The pushing- handle is not fully inserted into the pushing hole.

3. The pushing mechanism is not fully placed at the test position, so that the

clapper cannot be unlocked with the cabinet body

4. The cabinet body earthing interlocking is not released

7-3 The commissioning and operation work shall be carried out by specially trained personnel who

have a detailed understanding of the performance of the circuit breaker. The corresponding protection

and prevention measures must be considered in the work.

One of the preconditions for trouble free operation is to use the circuit breaker under normal working

conditions according to the corresponding provisions of GB /T 1984 and IEC 60694 standards.

● C

heck the circuit breaker for damage or any other harmful environmental impact. If there is such a

phenomenon, it should be eliminated before power on to restore to normal working conditions.

●

Remove dirt, especially on the surface of insulating parts. These may be due to contamination during

transportation or storage, which may affect the insulation performance of the product.

● C

heck the connection status of primary circuit contact, secondary circuit connection and grounding body.

●

Manual operation test.

8.

Maintenance

Maintenance must be carried out by AEG personnel or the user's personnel who are familiar with the

equipment and have been trained and qualified. If the maintenance is carried out by the user's personnel,

the user shall be responsible for the consequences of the repair.

8-1 During normal use, the circuit breaker is free of maintenance. Because the circuit breaker has the

characteristics of simple structure and durability, it has a long service life. The maintenance work is

related to the wear and aging of parts. In order to make the circuit breaker work reliably, the interval time

and range of maintenance work needed to be carried out will depend on the influence of working

environment, operation times, operation time and short circuit current breaking times and other factors.

8-2 Before maintenance, all auxiliary power supply must be disconnected and there is no danger of

power transmission again. The circuit breaker itself is open and the spring is not stored energy. In order to

Summary of Contents for VB 40.5

Page 1: ...VB 40 5 Vacuum Circuit Breaker VB 40 5真空断路器 User Manual 册 ...

Page 2: ......

Page 12: ...8 5 Overall dimensions Floor type 300mm apart ...

Page 13: ...9 Floor type 440mm apart ...

Page 14: ...10 Withdrawable 275mm apart Fixed connection 300mm apart ...

Page 15: ...11 Fixed connection 300mm apart ...

Page 17: ...13 Withdrawable 58 cores ...

Page 31: ...27 5 外形尺寸 落地式 相距300mm ...

Page 32: ...28 落地式 相距 440m ...

Page 33: ...29 车式 相距275mm 固定式 相距 300mm ...

Page 34: ...30 固定式 相距 300mm ...

Page 35: ...31 6 电气接线图 落地式 58芯 带推进机构辅助接点 ...

Page 36: ...32 车式 58芯 ...