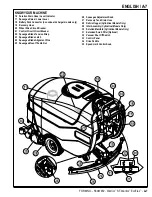

A-18 / ENGLISH

A-18

- FORM NO. - 56041972 - Warrior

™

ST, Warrior

™

EcoFlex

™

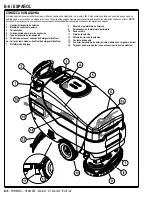

AFTER USE

1

Raise the brushes (or pads) and raise the squeegee. Move the machine to a service area.

2

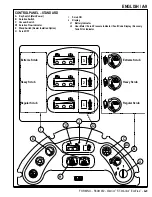

Turn the Master Key Switch

(A)

OFF and remove the key.

3

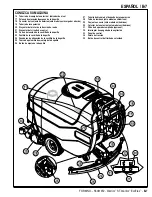

To empty the solution tank, pull the Solution Drain Hose

(16)

off the elbow. Direct the hose to a

fl

oor drain or bucket. Rinse the tank with clean water.

Inspect the solution hoses; replace if kinked or damaged.

4

To empty the recovery tank, remove the Recovery Tank Drain Hose

(27)

from its hanger and remove the cap (hold the end of the hose above the water level

in the tank to avoid sudden, uncontrolled

fl

ow of waste water). The Recovery Tank Drain Hose

(27)

can be squeezed to regulate the

fl

ow. Rinse the tank

and recovery tank switch(es)

(32)

with clean water. Inspect the recovery and vacuum hoses; replace if kinked or damaged.

SERVICE NOTE:

Make sure

you do not get any water down the Vacuum Motor Inlet Screen

(4)

while cleaning.

NOTE:

After each use, drain and rinse the recovery tank thoroughly and then

fi

ll the recovery tank about 1/3 full with clean water.

5

Remove the brushes or pad holders. Rinse the brushes or pads with warm water and hang up to dry. Allow buf

fi

ng pads to dry completely before using

again.

NOTE:

You can either remove the brushes manually or automatically by pressing and holding the Scrub OFF Switch

(H)

for 5 seconds

(EcoFlex disk

models only).

6

Remove the squeegee, rinse it with warm water and hang it up to dry.

7

Check the maintenance schedule below and perform any required maintenance before storage.

MAINTENANCE SCHEDULE

MAINTENANCE

ITEM

Daily

Weekly

Monthly

Yearly

Charge

Batteries X

Check/Clean Tanks & Hoses (clean recovery tank switches & vacuum inlet screen)

X

Check/Clean/Rotate the Brushes/Pads

X

Check/Clean the Squeegee

X

Clean Hopper on Cylindrical System

X

Check Each Battery Cell(s) Water Level (does not apply to gel cell batteries)

X

Inspect Scrub Housing Skirts

X

Inspect and clean Solution Filter

X

Clean Solution Manifolds on Cylindrical System

X

Purge Detergent System (EcoFlex only)

X

Lubricate the Machine

X

* Check Carbon Brushes

X

* Have Advance check the vacuum motor carbon motor brushes once a year or after 300 operating hours. The brush and drive motor carbon brushes check every

500 hours or once a year.

NOTE:

Refer to the Service Manual for more detail on maintenance and service repairs.

8

Store the machine in a clean, dry place.

9

Turn the Master Key Switch

(A)

OFF (O) and remove the key.

SERVICING THE VACUUM MOTOR

Have your Advance Dealer check the carbon motor

brushes once a year or after 300 operating hours.

IMPORTANT!

Motor damage resulting from failure to service

the carbon brushes is not covered under

warranty. See the Limited Warranty Statement.

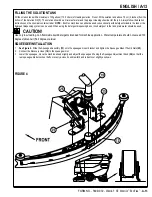

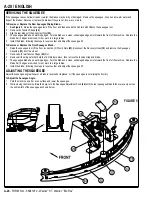

LUBRICATING THE MACHINE

Once a month, apply light machine oil to lubricate the:

•

General Pivot Points For the Squeegee Linkage

(A)

.

•

Squeegee mount angle adjustment knob threads

(B)

.

•

Squeegee Tool end wheels

(C)

.

•

General Pivot Points For the Brush Linkage

(D)

.

•

Scrub deck bumper wheels.

Once per quarter, Grease the following

•

Rear Caster Wheel Swivels

(E)

.