EN • 20

ENGLISH

FRANCAIS

NEDERLANDS

ES

p

A

ño

L

IT

ALIAN

o

DE

u

TSCH

664Y0200.C

Corrective measures

Problems

Condensation in the chimney:

Smell of flue gas:

Insufficient heating:

The burner switches to safety mode after lighting:

Noisy pump:

Not enough hot water:

Pump not running:

Burner fails to light:

The manual reset high limit thermostat is tripped:

Reasons

Chimney is cold and/or not lined

1

Boiler T° is set too low

2

Chimney blocked

3

Combustion spillage in the chimney

4

Insufficient or no ventilation in the boiler room

5

Boiler clogged

6

Burner clogged

7

Room thermostat T° set too low

8

Pump jammed or faulty

9

Boiler switch is in the Summer position or is faulty

10

Insufficient water in the system

11

Radiator valves closed

12

System not vented properly

13

Low gas pressure

14

Gas pipe too small

15

Boiler thermostat/potentiometer faulty

16

The electrical system is not earthed (properly)

17

System fuses have blown

18

System and/or boiler not vented properly

19

Not enough time allowed between large drawoffs

20

Drawoff flow too fast

21

Room thermostat faulty or not turned ON

22

Faulty Summer/Winter switch

23

Main switch is faulty or not turned ON

24

Faulty NTC sensor

25

Thermal reset high limit thermostat (95°C) activated

26

Manual reset high limit thermostat (103°C) activated

27

Faulty printed circuit board

28

P.c.b. fuse blown

29

Faulty burner fan

30

No PWM signa

31

Ignition electrode faulty or incorrectly set

32

Ionisation electrode faulty or incorrectly set

33

Burner connectors not inserted properly

34

Blocked gas valve

35

Faulty p.c.b. relay

36

Boiler thermostat/potentiometer faulty

37

Upper part of boiler not vented properly

38

NTC sensor incorrectly inserted in its pocket

39

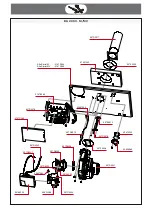

BuRNER CHARACTERISTICS

fault table

Summary of Contents for alfa Sprint M

Page 28: ......