100S

Reference Manual

24

OPERATION

6. Press the

Y

key. Enter the bolthole pattern’s center point on the Y-axis.

Use a decimal point and minus (-) sign if necessary.

7. Press the

ENTER

key.

8. Press the

ENTER

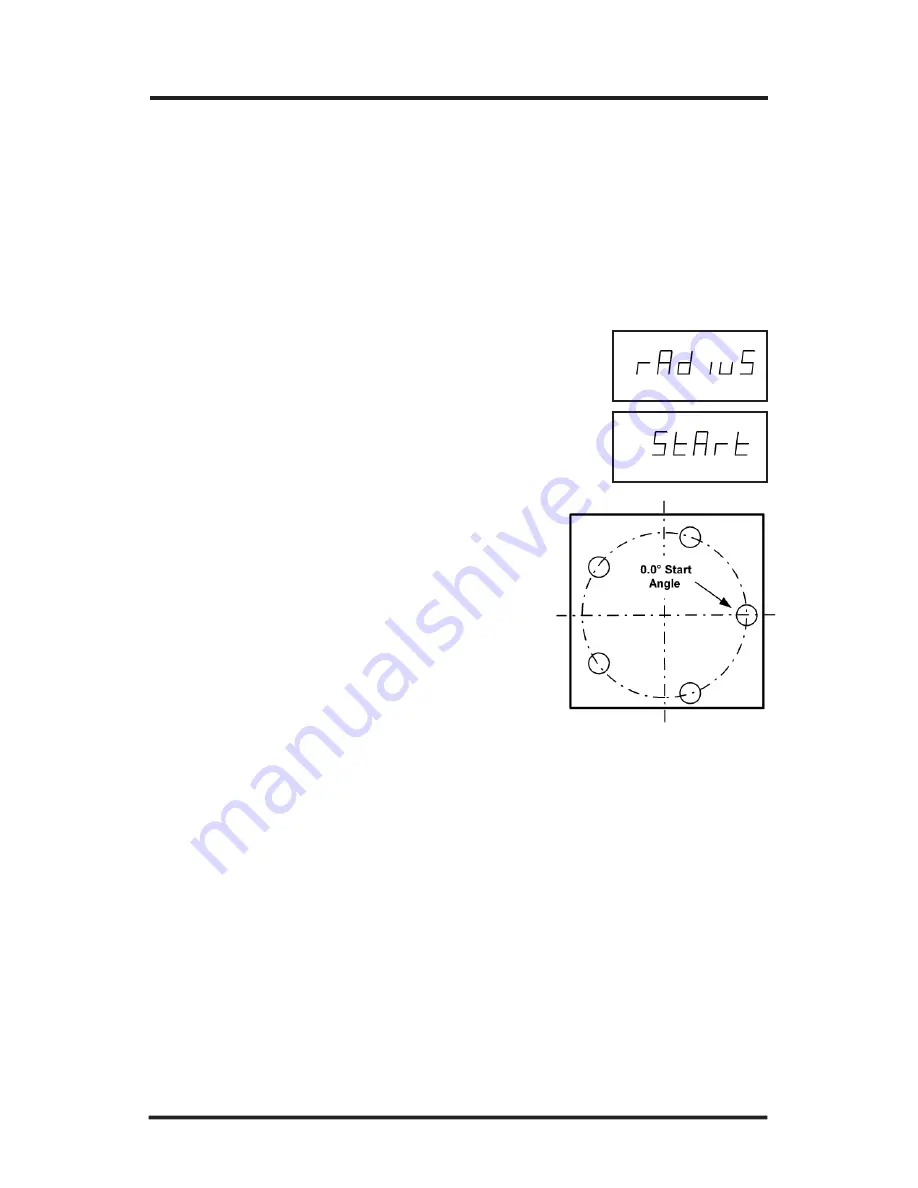

key again. “Radius” will appear.

9. Enter the radius of the circle pattern. Press

ENTER

.

10. Press

ENTER

again. "START" will appear on

the X-axis display.

11. Enter the start angle of the first hole in

the bolthole pattern. (0 degrees is at the

3 o’clock position.) Use a decimal

point and minus (-) sign if necessary.

12. Press

ENTER

to complete the pattern.