Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone:

1-888-967-5224 |

Website:

workaci.com

Page 3

GENERAL INFORMATION

The BACnet MS/TP / Modbus RTU Averaging Series

sensor is designed for use with electronic controllers

in commercial heating and cooling building manage-

ment systems. The ACI BACnet MS/TP / Modbus RTU

Averaging Series sensor monitor the average

temperature in commercial HVAC ductwork and

provides a better average temperature of the air

inside the duct compared to a single point duct

sensor. Averaging sensors are sold in either Copper

or Flexible Averaging variations. The Copper

Averaging sensors include a continuous sensing

element, which covers the entire length of the probe.

The Flexible Averaging sensor has either 4 or 9

sensing points depending on the length. It uses

BACnet MS/TP or Modbus for RTU for physical

connection to a BAS or controller, has dip switches to

set addresses and baud rate, parity and stop bits

(Modbus RTU only), and has on board end-of-line

termination. There is no analog output.

WIRING INSTRUCTIONS

The BACnet MS/TP /Modbus RTU Averaging Series

temperature sensor has a depluggable terminal

block located on the front of the PCB. For ease of

wiring, we recommend removing the block, wiring,

and reattaching before mounting. 16 to 22 AWG

two conductor shielded cable is recommended for

powering the sensors.

ACI recommends using Belden 3105 or compatible

cable for RS-485 communication wiring. This wire has

120 ohm input impendence. The terminal blocks

allow for (1) or (2) wires to be connected in each

position for daisy chaining. Daisy chain the RS-485

wiring and do not use “Star” or “T” wiring. Avoid

running communication wires next to AC line

voltage wires. These can be sources of noise that can

affect signal quality.

PRECAUTIONS

• Remove power before wiring. Never

connect or disconnect wiring with power

applied.

• It is recommended you use an isolated

UL-listed class 2 transformer when powering

the unit with 24 VAC. Failure to wire the

devices with the correct polarity when

sharing transformers may result in damage

to any device powered by the shared

transformer.

• If the 24 VDC or 24VAC power is shared with

devices that have coils such as relays,

solenoids, or other inductors, each coil must

have an MOV, DC/AC Transorb, Transient

Voltage Suppressor (ACI Part: 142583), or

diode placed across the coil or inductor. The

cathode, or banded side of the DC Transorb or

diode, connects to the positive side of the

power supply. Without these snubbers, coils

produce very large voltage spikes when

de-energizing that can cause malfunction or

destruction of electronic circuits.

MOUNTING INSTRUCTIONS

Drill a 3/8" (9.53 mm) hole in the duct. Gently uncoil

the copper tubing and insert the averaging

element through the hole until the foam pad is

tight to the duct. The sensor should then be strung

in a criss-cross pattern throughout the duct using

the mounting clips provided - see

FIGURE 5

(P.3)

.

Use a pattern that covers the greatest surface area

of the duct to ensure that there is no stratification.

When bending the copper tubing, be careful that

you use a gradual bend and that you

DO NOT

kink

the copper tubing. Bends should be a minimum of

2” (50.8 mm). Each unit includes nylon wire ties

and mounts for mounting. Optional copper

capillary (ACI Item #

130525)

or universal plastic

mounting clips (ACI Item #

145421

) can be

ordered. Plastic mounting clips will help insulate

the copper sensing element from the metal duct.

The capillary clips help avoid kinks when bending.

When using Flexible averaging, do not cover the

heatshrink that is located throughout the sensor

(sensing points).

Drill pilot holes for the (2) mounting screws. Use the enclosure flange as a guide, or use the

dimensions listed below to measure out. Now fasten and insert (2) screws #8 x 3/4" TEK (provided and

recommended) through the mounting holes in the flange and tighten until the unit is held firmly to

the duct. Make sure the foam pad is tight to the duct to eliminate any possible air leaks.

For optimal temperature measurement, follow these tips:

•

Mount coil horizontal for vertical stratification.

•

Mount coil vertical for horizontal stratification.

•

The sensor must be spread evenly over the full duct.

•

The entire length of the sensor coil must be installed completely inside the duct. Do not have any part of

the sensor exposed to exterior air.

•

When installing the sensor near air-handling units, place the sensor downstream from the fan discharge.

The stratified airstream will be more uniform across the duct cross-section. If the air is not well-mixed, the

reading may be inaccurate.

•

If UV Lights are installed in duct, do not use Flexible Averaging. There is no UV protectant on outer cable

jacket. Copper averaging must be used in this situation.

BACnet MS/TP and Modbus RTU

INTERFACE

(Continued)

ACI’s Modbus RTU sensors are slave devices. Only

one master is connected to the bus and several

slave nodes are connected to the same trunk. The

Master initiates communication. The slave nodes

only respond to a request from the Master. Slave

nodes do not communicate with each other.

Each branch must have all devices connected with

(+) connected to (+) and (-) connected to (-). If a

shielded cable is used, this is not to be connected

to the devices. The shield cable should only be

connected on one end to earth ground, usually at

the controller. The start and end of each branch

should have a termination resistor at the device

level or at the controller.

Each device must be configured for the correct

baud rate and have a unique address in each

branch. The baud rate for the branch is set by the

controller. This product has auto-baud for ease of

network configuration but setting the baud rate

using the DIP switches is recommended.

Note:

Auto-baud feature does not function when

Modbus is the selected protocol.

BAUD RATE SELECTION

By default, BACnet Protocol and Auto-Baud is

factory set. If the sensor is field adjusted for

Modbus RTU, the baud rate should be selected at

this time to match the Master configuration. If

Modbus RTU protocol is selected it is

recommended the sensor unique address is

selected at this time. Switches 8-10 are used to

set the BACnet and Modbus baud rate. Refer to

TABLE 3

for switch settings. Where (0) is OFF and

(1) is ON. If the system’s baud rate is known, it is

recommended to set the specific baud rate to

match the system.

If the device is powered when

a change is made, the device must be power

cycled or reset for changes in baud rate to be

made.

BACnet MS/TP and Modbus RTU INTERFACE

The BACnet Master-Slave/Token-Passing (MS/TP) and Modbus Remote Terminal Unit (RTU) data link

protocol uses EIA-485 as a two-wire, daisy chain network. A branch is a discrete chain of devices connected

to a controller. The max number of devices per segment is 32, as per the BACnet and Modbus

specifications. 4000 ft (1219.2 m) is the maximum recommended length for a segment, which includes all

devices from the controller to the last device in the daisy chain.

BACnet or Modbus RTU protocol selection is done via SW4 switch. Place dipswitch #4 to the OFF position

for BACnet and the ON position for Modbus. Refer to

FIGURE 6

.

ACI’s BACnet sensors are master devices. Only master nodes are allowed to send and receive tokens on the

MSTP network.

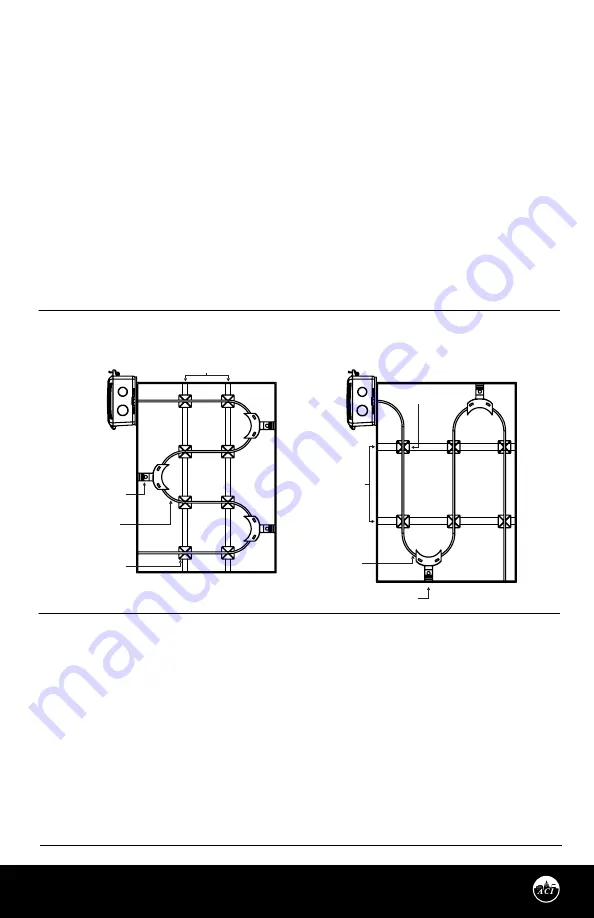

VERTICAL COILING

OPTIONAL COPPER OR

PLASTIC CAPILLARY CLIP

WIRE TIE MOUNT

HANGER STRIPS

OPTIONAL COPPER OR

PLASTIC CAPILLARY CLIP

WIRE TIE MOUNT

HANGER STRIPS

FIGURE 5:

HORIZONTAL AND VERTICAL COILING

HORIZONTAL COILING

MIN. BEND

RADIUS 2” (50.8 mm)

MIN. BEND

RADIUS 2” (50.8 mm)

EOL TERMINATION RESISTANCE

SELECTION

RS-485 requires that the last device in a chain

have a termination resistor. This is controlled

using a jumper in the EN (enabled) position

marked on

FIGURE 7

. When the jumper is set to

EN (enabled), a 120Ω resistance is added in

parallel to the data line. When the jumper is set to

DIS (disable), the resistance is not added. By

default, the jumper is placed in the DIS (disabled)

position.

RESET

The reset button can be used to reset the device

without disconnecting power. The location of

this button is shown in

FIGURE 2 (P.1).

Version: 2.0

I0000932