ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.com

Stand 03.2021

ACE Stoßdämpfer GmbH · www.ace-ace.com

21_22_0019 Issue 05.2022

3

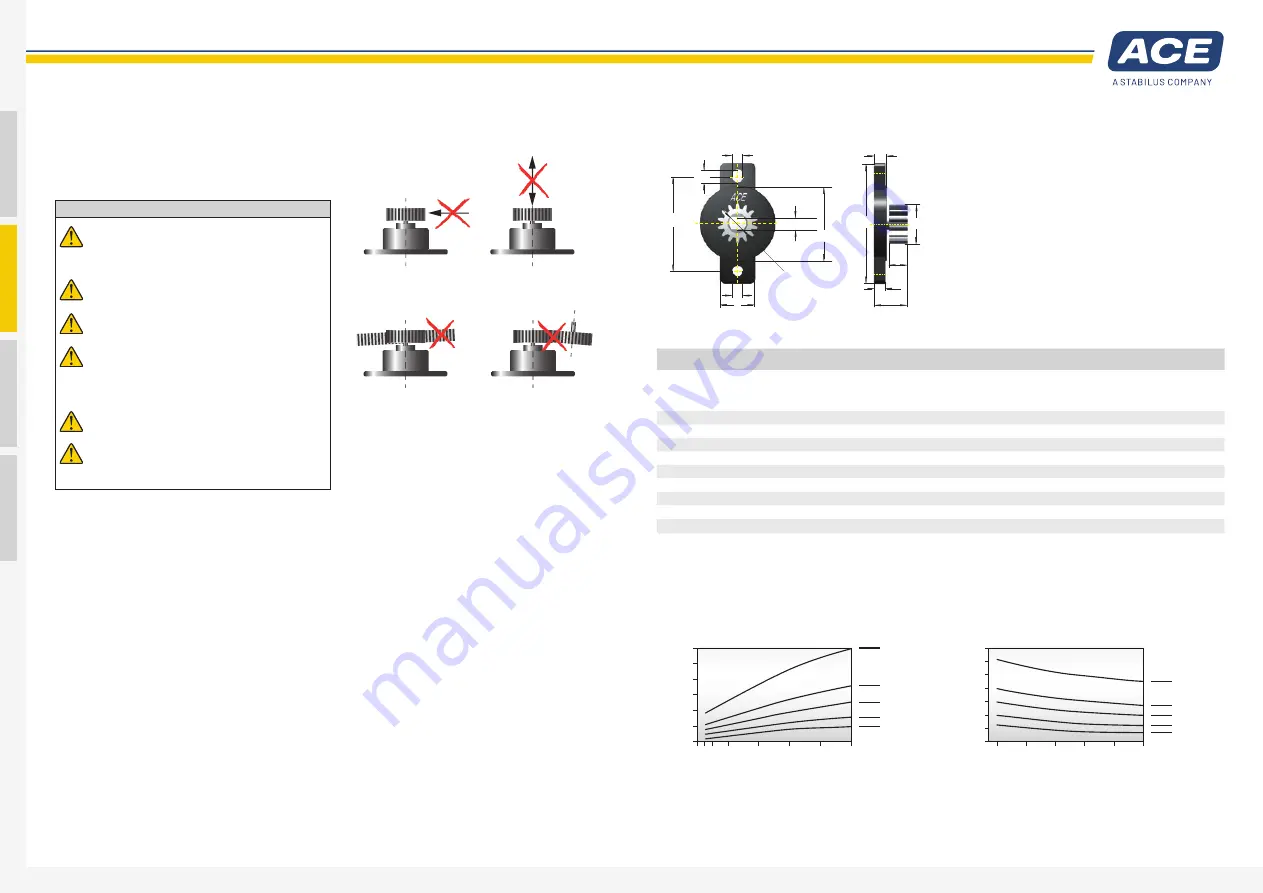

Mounting instructions and mounting accessories

Construction size:

Ø 15 mm

Max. speed:

50 rpm

Lifetime:

50,000 cycles (1 cycle = 360° left-hand,

360° right-hand), at least 80 % of the original damping torque

after this. The service life may be significantly higher or lower,

depending on the application.

Operating temperature range:

0 °C to +50 °C

Pressure angle:

20°

Material:

Outer body, shaft, gear: Plastic

Mounting:

in any position

Tooth:

Involute gearing

P.C.D.:

7 mm

Number of teeth:

14

Module:

0.5

Damping medium:

Silicone oil

Mounting information:

Attach the damper to the securing tabs

in such a way that the part to be braked cannot exert any side

forces on the damper. Turn the shaft opposite to the damping

direction to avoid damaging the free-wheel mount. No axial or

radial forces may be introduced via the shaft. The rotary axis was

not designed for side loading (see diagrams).

Safety instructions:

Do not use rotary dampers as supports.

Packaging disposal:

Please dispose of the transportation pack-

aging in an environmentally-friendly manner. Recycling packaging

materials saves raw materials and reduces waste. The packaging

materials do not contain any prohibited materials.

Angular offset

Misalignment

Side loading

End loading

Note! The rotary axes, square mounts or free-wheel

mounts are not designed for side loading.

Installation instructions

Before installation and use check whether the identification num-

ber on the product or on the packaging matches the respective

designation on the delivery note.

Rotary dampers are maintenance-free and ready-to-in-

stall.

WARNING

The specified rated damping torque

applies at a temperature of 23 °C or a

speed of 20 rpm.

The damping torque can change depending

on the temperature or speed. Please observe the characteristic

curves in the mounting instructions.

The flap/mass can fall off during installation and removal

of the rotary damper.

Secure moving flap/mass against falling

down!

Depending on the application, failure of the product could

lead to personal injuries and/or material damage.

Use

additional safety elements.

Exceeding the permissible temperature range, the max.

speed, the cycle number and the specified damping torque

can lead to premature failure or destruction of the rotary

damper.

Operating temperature range, speed of 50 rpm, cycle

number of

10/min. and the specified damping torque must be maintained.

Dirt, swarf and aggressive liquids can cause premature

failure of the rotary damper.

Protect or encapsulate rotary

damper from external materials in the surrounding area.

Do not use rotary dampers in high-pressure or vacuum

range.

1.5

1.0

0.5

0

101

600

450

300

200

Ncm

0 3 5 10

20

30

40

50

rpm

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

0 10 20 30 40 50

101

600

450

300

200

Ncm

°C

2.6

19 +/- 0.05

2.1

2.1

7

2.5 +/- 0.05

15

3.6 +/- 0.05

Ø

Ø

Ø

8

24

2.2

3.7

2.5

6.6 (5.4)

Ø

Dims. in ( ) without gear

Performance data

TYPES

1

Damping torque

Ncm

Damping direction

Gear

Module

Number of

teeth

Pressure

angle

°

P.C.D.

mm

Weight

kg

FRT-G2-200

0.20 +/- 0.07

two-sided

without

-

-

-

-

0.00060

FRT-G2-300

0.30 +/- 0.08

two-sided

without

-

-

-

-

0.00060

FRT-G2-450

0.45 +/- 0.10

two-sided

without

-

-

-

-

0.00060

FRT-G2-600

0.60 +/- 0.12

two-sided

without

-

-

-

-

0.00060

FRT-G2-101

1.00 +/- 0.20

two-sided

without

-

-

-

-

0.00060

FRT-G2-200-G1

0.20 +/- 0.07

two-sided

with

0.5

14

20

7

0.00080

FRT-G2-300-G1

0.30 +/- 0.08

two-sided

with

0.5

14

20

7

0.00080

FRT-G2-450-G1

0.45 +/- 0.10

two-sided

with

0.5

14

20

7

0.00080

FRT-G2-600-G1

0.60 +/- 0.12

two-sided

with

0.5

14

20

7

0.00080

FRT-G2-101-G1

1.00 +/- 0.20

two-sided

with

0.5

14

20

7

0.00080

1

The indicated damping torques refer to a rotational speed of 20 rpm and an ambient temperature of 23 °C.

Characteristic curves

At 23 °C ambient temperature

FRT-G2

At 20 rpm speed

Provide an external guide or support.

On request:

Special designs available on request. Toothed

plastic racks (modules 0.5 to 1.0) are available for the rotary

dampers with pinions.

Rotary Damper FRT-G2 (continuous rotation)