Assembly Instructions / Turbochargers A131-R, A136-R

4 Installing the turbocharger / 4.4 Placing the turbocharger on the bracket

© Copyright 2023 Turbo Systems Switzerland Ltd. All rights reserved.

HZTL455311P0044_EN

Rev. A

April 2023

4.4

Placing the turbocharger on the bracket

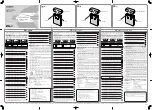

Fig. 10: Placing the turbocharger on the bracket

A

Standard nut

u

Before placing, ensure that the oil and water connection covers are removed.

u

Before placing, make sure that the oil inlet holes on the bearing casing are correctly positioned

opposite the bracket and that the oil supply is ensured during operation.

1.

Make sure that the O-rings (03) are undamaged and positioned correctly in the slots.

2. Attach the lifting gear to the swivel lifting eyes (S) and loop around the gas outlet casing.

3. Position the turbocharger on the bracket (04) and align it. If present, observe the positioning

pin (05) or positioning sleeve (07) in the bracket.

Safeguard against wrong fitting (only for water-cooled bearing casings)

Depending on the bracket version (04), two positioning pins (05) can be used for positioning and

safeguarding against wrong fitting of the turbocharger. Therefore the turbocharger must always be

removed from and installed on the bracket vertically.

Page

13

/

17

Summary of Contents for Turbocharger A131-R

Page 2: ......