Absco Industries

Assembly Instruction Manual

ABSCO WORKSHOP SHED

MODEL: 60303WK

5.96mW x 3.00mD x 2.10mH

Model: 60303WK

17/03/21

1.20

23

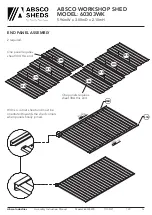

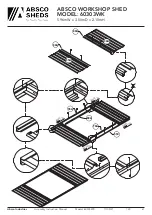

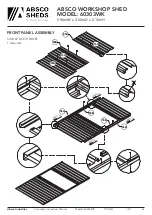

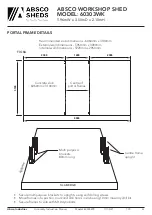

DOOR PANEL ASSEMBLY

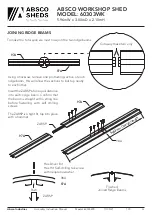

Vertical door channels are

installed in the opposite

orientation compared to the

horizontal door channels.

Short fl ange

of channel

Long

fl ange of

channel

SINGLE DOOR

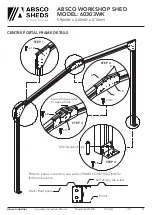

58C

58C

SNAPT

TE

i

SNAPT TE

i

12A

B

B

58B

58A

D

D

D

D

1 required.