Absco Industries

Assembly Instruction Manual

ABSCO PREMIER SHED

MODEL: 30232GK

3.00mW x 2.26mD x 2.10mH

Model: 30232GK

1.12

8

17/03/21

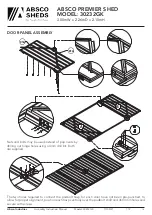

PRE-ASSEMBLY OF SPLICED CHANNELS

NOTE: Some channels may have holes in them - You will

need to redrill holes where CSJ joining channel covers

them.

Join together 20 x channel sections using 10 x channel joiners (Part CSJ)

2x 81AR

2x 81AL

2x 60AR

2x 60AL

1x 55AR

1x 55AL

1x 55CR

1x 55CL

1x 55BR

1x 55BL

1x 81BR

1x 81BL

2x 81CR

2x 81CL

2993mm (117.8”)

2253mm (88.7”)

81BL

55BL

55CL

55AL

60AL

81AL

81BR

55BR

55CR

55AR

60AR

81AR

= 2x 81A

= 2x 60A

= 1x 55A

= 1x 55C

= 1x 55B

= 1x 81B

= 2x 81C

81CL

81CR