Absco Industries

Assembly Instruction Manual

ABSCO REGENT SHED

MODEL: 30222RK

3.00mW x 2.18mD x 2.10mH

Model: 30222RK

1.1

18

17/03/21

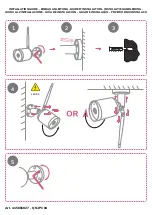

DOOR PANEL ASSEMBLY

Nuts and bolts may be used instead of pop rivets by

drilling out hinge holes using a 4mm drill bit. Both

are supplied.

The two holes required to connect the padbolt hasp for each door have not been pre-punched, to

allow for proper alignment, position each hasp centrally over the padbolt shaft and drill 3mm holes and

secure with screws.

91A

91A

A

B