– 30 –

The procedure to enable the velocity feature is outlined below:

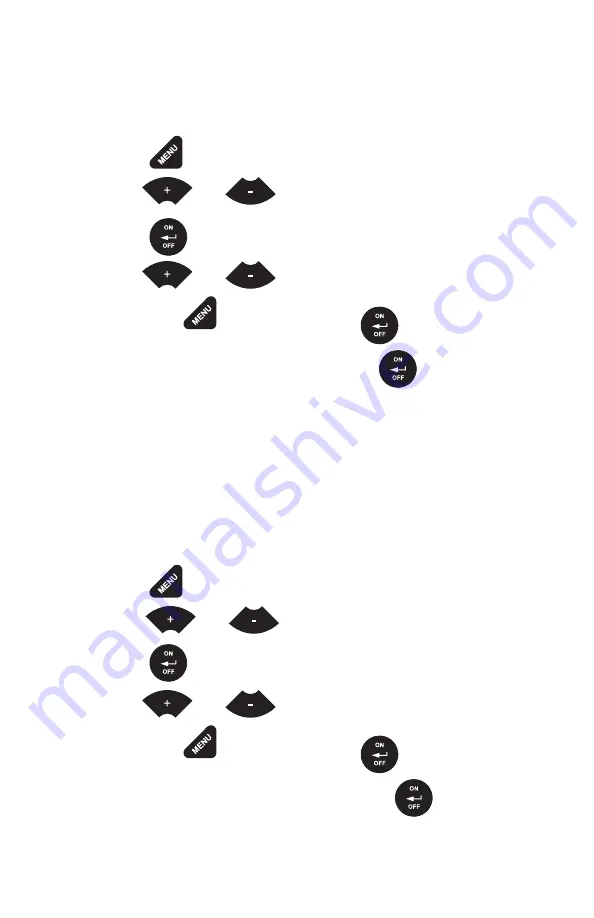

1. Press the

key to access the menu items/features.

2. Use the

and

keys to scroll through the items/features until the

VX feature isbeing displayed.

3. Press the

key to edit the setting. The edit icon will be illuminated and

flashing.

4. Use the

and

keys to select the on/off option.

Note

: Pressing the

key prior to pressing the

key will abort to the

measurement screen without saving changes.

5. When the desired VX setting is displayed, press the

key to set the status

and return to the measurement screen.

7.10 Probe Diameter

The PROB feature was added to improve linearity when using a specific probe diameter.

The default standard setting is (.250”), and works reasonably well using a general

correction curve for all of our dual element transducers in our range. However, selecting

the exact diameter of the transducer being used will offer additional linearity (accuracy).

The three options found in our range of transducers are (.187, .250, .500) inches. All of

our transducer diameters and frequencies are marked on top of the transducer housing.

The procedure to select the probe/transducer diameter is outlined below:

1. Press the

key to access the menu items/features.

2) Use the

and

keys to scroll through the items/features until the

PROB feature is being displayed.

3. Press the

key to edit the diameter setting. The edit icon will be illuminated

and flashing.

4. Use the

and

keys to select the diameter option.

Note

: Pressing the

key prior to pressing the

key will abort to the

measurement screen without saving changes

5. When the desired PROB setting is displayed, press the

key to set the

diameter and return to the measurement screen.