Above

Air

™

MissionCritical

™

A/C’s

AboveAir

Technologies

(MC22-L12)

16

Guide Specifications

Guide Specifications -

MC

-

2x2

™

Mission

Critical

(1-3 Tons)

2.5 Accessories

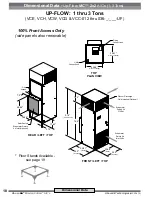

2.5.1 Plenum Discharge Box

(UF - Up-Flow Units)

A (2-way, 3-way or ducted) plenum

discharge box shall be provided for field

installation to the top of the up-flow unit.

The plenum box shall be 18.5 inches

high, insulated and powder-coat painted

to match the color of the unit.

2.5.2 Floor Stand

A ____ inch high floor stand shall be

factory provided for field installation. The

floor stand shall have adjustable legs

with vibration isolation.

2.5.2.1 Turning Vanes

Turning vanes shall be factory provided

with the floor stand to direct the dis

-

charge air either to the front or rear of

the unit.

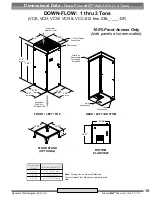

2.5.3 Condensate Pump

(Factory Installed - UpFlow)

A condensate pump shall be factory

provided and installed within the indoor

evaporator section

(Up-Flow Air Pattern

Configurations)

. The condensate pump

shall be provided with dual internal float

switches: one for pump operation initia

-

tion and the other for pump reservoir

overflow safety.

(

Note:

Down-Flow unit Condensate Pump

Option requires field installation of the pump

outside of the A/C unit. A condensate pump

fused power supply terminal connection

shall be factory provided within the A/C unit

evaporator.)

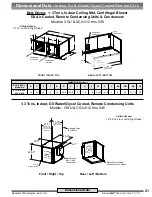

2.5.4 Hot Gas Bypass Systems

2.5.4.1 Hot Gas Bypass To

Evaporator Inlet

Each refrigerant circuit shall be pro

-

vided with a factory installed hot gas

(discharge) bypass valve. The hot gas

bypass valve shall be designed to supply

hot gas to evaporator inlet as required to

provide coil freeze-protection and capac

-

ity modulation under low load conditions.

2.5.4.2 Hot Gas Bypass To

Suction Line with

Quench Valve

(VCH/XPU-CCU/CWU-CGU

Remote Condensing Units

3

rd

Line Not Required!)

Each refrigerant circuit of the Split DX

system shall be provided with a fac

-

tory installed hot gas bypass system to

include: hot gas (discharge) bypass and

desuperheating quench. The hot gas

bypass system shall be designed to sup

-

ply hot gas and liquid refrigerant to the

suction line as required to provide coil

freeze-protection and capacity modula

-

tion under low load conditions. All hot

gas bypass components shall be factory

installed and shall not require additional

field refrigerant lines on split DX sys

-

tems.

2.5.5 Suction-Line Accumulator

Each refrigerant circuit shall be provided

with a factory installed Suction-Line Ac

-

cumulator to prevent liquid slugging of

the compressor and excessive refriger

-

ant dilution of the compressor oil during

low load conditions. The accumulator

shall return refrigerant and oil to the

compressor at a sufficient rate to main

-

tain both system operating efficiency and

proper oil level. The accumulators shall

be wrapped with a 1/2” closed-cell neo

-

prene insulation to prevent sweating.

2.5.6 Main Power, Non-Fused

Disconnects

(Remote Condenser Section)

The remote condensing unit (or con

-

denser) shall be factory provided with

a main power non-fused disconnect for

field installation. The disconnect shall be

NEMA rated for indoor or outdoor instal

-

lation as required.

2.5.7 Firestat

(Factory Installed)

A Firestat shall be factory installed in the

return air stream of the unit and wired to

the A/C unit electrical control panel. The

Firestat shall shut-down all A/C system

operations upon sensing a high return air

temperature condition.

2.5.8 Smoke Detector

(Factory Installed)

A Smoke Detector shall be factory

installed in the return air stream of the

unit and wired to the A/C unit electrical

control panel. The Smoke Detector shall

shut-down all A/C system operations

upon activation.

2.5.9 Remote Water-Leak

Detector

A remote water-leak detector shall be

factory provided for field installation. The

remote water-leak detector shall be wired

to shut down all A/C unit water producing

functions upon sensing a water leak.

2.5.10 Flow Switch -

Water/Glycol Condenser

A factory installed flow switch shall

shut-down / lockout compressor opera

-

tion prior to the high refrigerant pressure

switch alarm upon sensing a loss or low

dx condenser water/glycol flow. A flow

switch alarm shall be indicated both via

MC-2000 microprocessor display and

auxililary dry-contact terminal connec

-

tion.

2.5.11 Compressor Acoustic /

Sound Jacket

Each compressor shall be provided with

a factory installed compressor sound

jacket with snap closure system for ease

of removal and reinstallation. Sound

jackets shall have a noise reduction coef

-

ficient (NRC) of 85 per ASTM and C-423

and a sound transmission lost (STC) of

11 per ASTM E-90.