22

UniGear ZS1

I N S T A L L A T I O N , O P E R A T I O N A N D M A I N T E N A N C E

—

5 Assembly of the switchgear on site

In order to obtain an optimum installation sequence

and ensure high quality standards, on-site

installation of the switchgear should only be

carried out by specially trained and skilled

personnel, or at least by personnel supervised

and monitored by responsible persons.

5.1 General

On commencement of installation on site, the

switch room must be completely finished. This

means it must be provided with lighting and an

electricity supply. In addition, it must be lockable,

dry and with facilities for ventilation. All the

necessary preparations, such as wall openings,

ducts, etc., for routing the power and control

cables up to the switchgear must already be

complete. The ceiling height must be sufficient

for the opening travel of the pressure relief plates

(Higher than 3 m).

The ceiling must be high enough for the assembly

of a pressure relief duct (Higher than 3 m).

Compliance with the conditions for indoor

switchgear according to IEC 62271-1, including

the conditions for the indoor temperature class

must be ensured.

5.2 Foundations

It is recommended that the switchgear is installed

on the base irons of a “C” profile shape set into

the concrete floor of switch room.

Further structural data guidelines enable a rough

calculation of the space required to be made and

the planning of the room design for a switchgear

project.

When the final construction documents are

compiled for the execution of a building, the

binding data supplied by ABB for a particular

case must always be taken into account!

5.2.1 Method of installation A – Installation of

the base irons

Due to different switchgear dimensions, one or

more parts make up the base irons. Their

installation is usually carried out by site personnel

and should, if possible, be performed under the

supervision of an ABB specialist.

Method of installation - Installation of the base

irons:

•

When base irons are composed of several parts,

connect them with a bolt in the required order

and position them horizontally

•

Lay the irons in the specified position on the

concrete floor as shown in the relevant foundation

drawing

•

Mark out holes for drilling. These holes are

for the anchoring bolts that will fix the base

irons in the floor

•

Put the plugs in the holes and use the bolts

to attach the base irons to the floor. Do not

tighten the bolts until the base irons have been

correctly leveled

•

Carefully level the base irons both longitudinally

and transversally over the entire length and

correct the height by using strips with a suitable

thickness and a levelling instrument. Usually

the top edge of floor frame should be 2 mm

above the finished floor surface (Fig. 26, 29)

Tolerances for laying the floor frame are:

•

Evenness tolerance: ±1 mm within a measuring

length of 1 m

•

Straightness tolerance: 1 mm per 1 m, but not

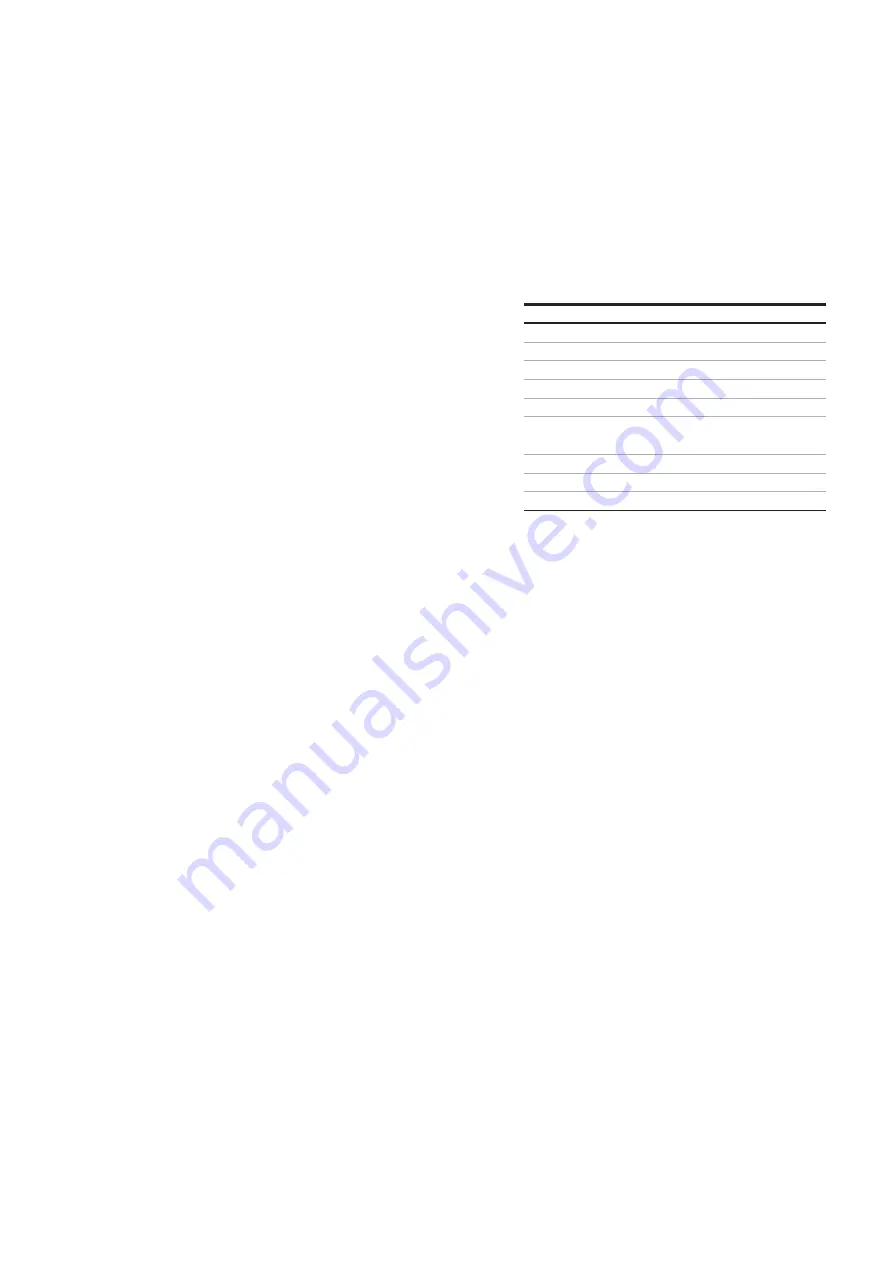

Rated voltage

Panel width FT

Aisle width

1)

G

Switchgear room door width

Switchgear room door height

2)

Opening in ceiling if transported

through roof:

Width

Length

Ceiling load

3)

kV

mm

mm

mm

mm

mm

mm

kg/m

2

12

500

1300

700/1200

2400

1000

1500

1200

Dimension chart of structural data (Also see figures 5/1 to 5/11)

1) Pay attention to the appropriate national standards.

2) Applies to low-voltage compartments of standard height.

3) Approximate numbers depending on the type of panels.

more than 2 mm over the entire length of the

frame

•

After levelling the base irons, the bolts can be

tightened. The adjusted position of the base

irons on the concrete floor must not be changed

during this operation

Check again and, if need be, correct any deviations.

•

Weld the individual parts of the base irons

inside the “C” profile together at the seams

so that a conductive connection is achieved

•

When the floor top covering is applied, carefully

backfill the floor frame, leaving no gaps

•

The base irons must not be subjected to any

harmful impacts or pressures, particularly during

the installation phase

If these conditions are not respected, problems

during switchgear assembly and possibly with

movement of the withdrawable parts, as well as

with the opening and closing of the doors cannot

be ruled out.

5.2.2 Method B – installation on the levelled

concrete floor

Installation directly on the levelled concrete floor

makes much higher demands on the floor levelling,

which must, in this case, fulfil the same tolerances

as the base irons during method A installation.

Fastening is carried out by anchoring bolts in the

concrete floor.

•

Clean the switchgear installation area carefully

•

On the slab, visibly trace the perimeter of all

the units making up the switchgear according

to the relevant draw-ing, taking the minimum

wall and obstacle clearances into account

•

Level the floor both longitudinally and

transversally, evenness tolerance is ±1 mm over

a measuring length of 1 m

•

Drill the floor at the intended fixing points,

referring to the slab drilling drawings. To make

the holes, use a hammer drill with a bit according

to the steel plugs used

•

Insert the plugs in the holes and put the individual

panels on the traced perimeters of the units

to create the switchgear

•

Level the units and then bolt them together

in the front and rear part

•

Fix the units with bolts with special washers

(the coupling material is supplied on request)

•

In the case of a metal floor - to make the holes,

use a drill with a suitable bit for the type of

fixing to be made (through or threaded hole)

5.2.3 Method C – installation on a raised false floor

In this case, fastening of the units is carried out

by welding outside panels to the steel floor frame

in the places where the frame is larger than the

base of the switchgear, i.e. on the outside lateral

walls of the unit row. This method of installation

is not recommended if seismic resistance is

required.

•

Clean the installation area

•

After installation of the frame, take any necessary

measures for perfect earthing of the frame with

galvanized steel strips with min. dimensions

30x4 mm. Two earthing connections are

recommended for a panel row longer than

approx. 5 panels

•

Place the units on the frame according to the

relevant foundation drawings, taking the

minimum wall and obstacle clearances into

account

•

Level the units and then bolt them together

in the front and rear part

•

Carry out attachment by welding the outside

panels to the steel floor frame in the place

where the frame juts out from the switchgear

bottom, i.e. on the outside lateral walls of the

unit row. This method of installation is not

recommended if seismic resistance is required

•

In the case of a metal floor - to make the holes,

use a drill with a suitable bit for the type of

fixing to be made (through or threaded hole)