Page 3–28

2101510 Rev. AG

15)

Insert the tubing with the ferrule into the corresponding input port located on the

NGC feed-through assembly. Move the Valco nut down onto the ferrule, screw

into the port and tighten.

16)

Repeat for each additional sample stream.

Do not over-tighten. After securing the tubing, check for gas

leaks.

17)

Measure and cut vent tubing to sufficient length to guarantee that purge coils

vent outside of enclosure. Feed vent tubing through the sample boot.

18)

Make necessary bends in the tubing to ease installation of the tubing into the

required fittings on the end of the sample conditioning module purge coil.

19)

Follow Heat Trace manufacturer’s suggested installation instructions for applying

Heat Trace equipment to additional sample streams.

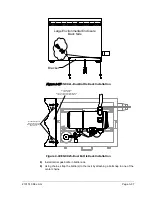

3.16 ENC82L Optional Pwr/Comm Outlet Box Assembly

If installing the NGC inside a ENC82, use this procedure to

install the optional RS-232/RS-485/RS-422 outlet box if

required; otherwise, continue to the next applicable

instructions. Before beginning, review the procedure and the

materials required for installation.

These instructions are only applicable to the large

environmental enclosure. This option is not available for the

small enclosure.

3.16.1 Materials

•

1 ea. outlet box assembly

•

1 ea. internal NGC connection assembly

•

1 ea. flexible cable assembly

•

1 ea. DC power switch box

•

1 ea. support bracket

•

2 ea. 10-32 x ¾” SS pan head screw, phillips

•

2 ea. #10 SST flat washer

•

2 ea. #20 SST split washer

3.16.2 Customer-Supplied Materials

•

14 AWG wire

•

Materials for external wiring (to outlet box) not provided by Totalflow. Quantity to

be determined by the technician based on installation and local codes.

3.16.3 Instructions

1)

Gain access to rear termination panel by loosening the countersunk hex

socket locking set screw in the rear end cap using a 1/16” hex wrench,

then unscrewing the end cap.

2)

Remove hub plug from the bottom most access hub.

3)

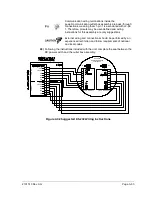

Beginning with the internal connection assembly (see

), feed the 13”

wire bundle (elbow end of assembly) through the open hub. Continue to pull wire

past the terminations until the nipple fitting is in position to screw into the hub.